Shell cutting device for electric connector production and machining

A technology of electrical connectors and cutting devices, which is applied in the field of shell cutting devices for the production and processing of electrical connectors, can solve the problems of inconvenient continuous cutting, inconvenient shell, and low cutting efficiency, and achieve convenient continuous cutting, high cutting efficiency, The effect of ensuring cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

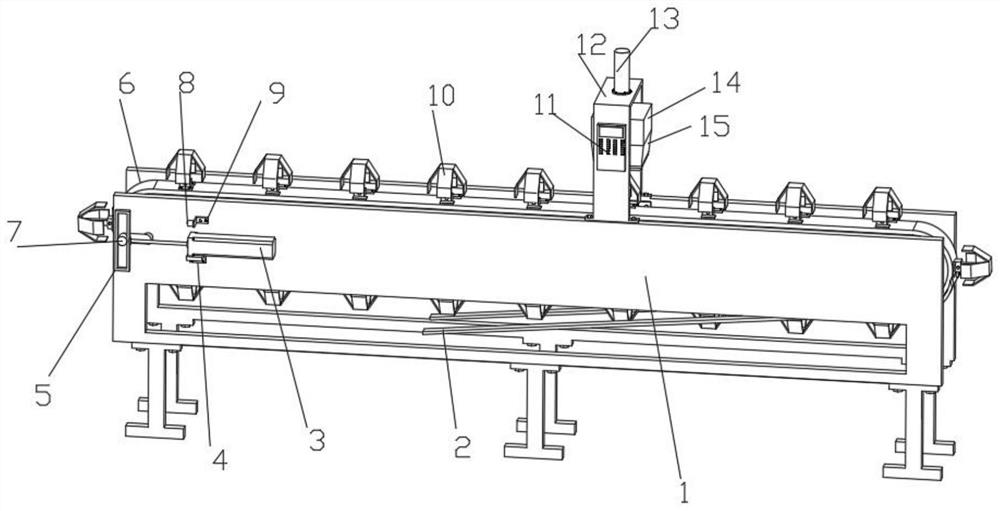

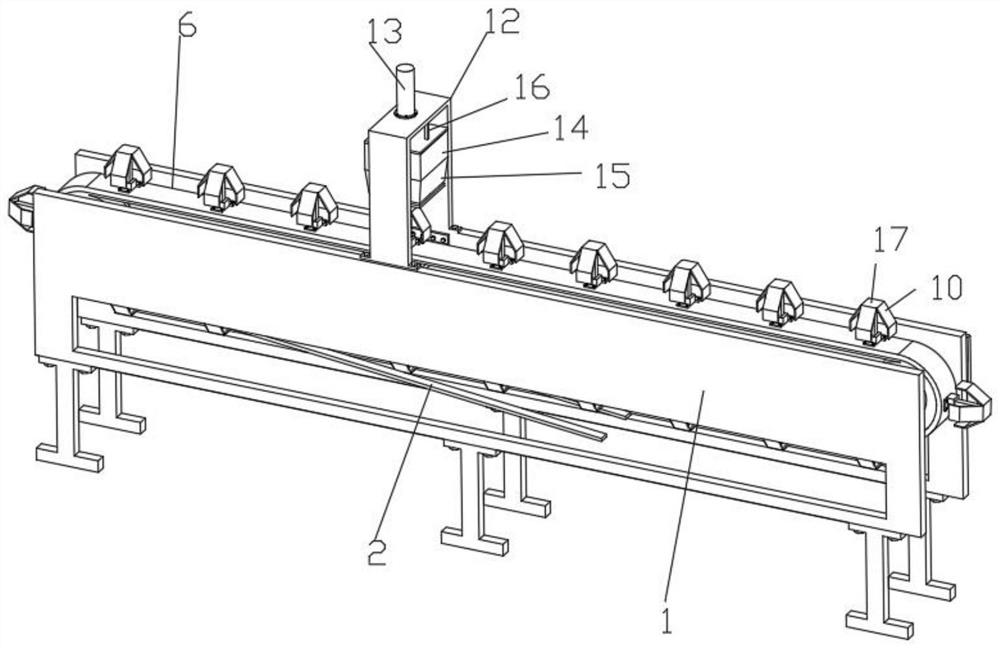

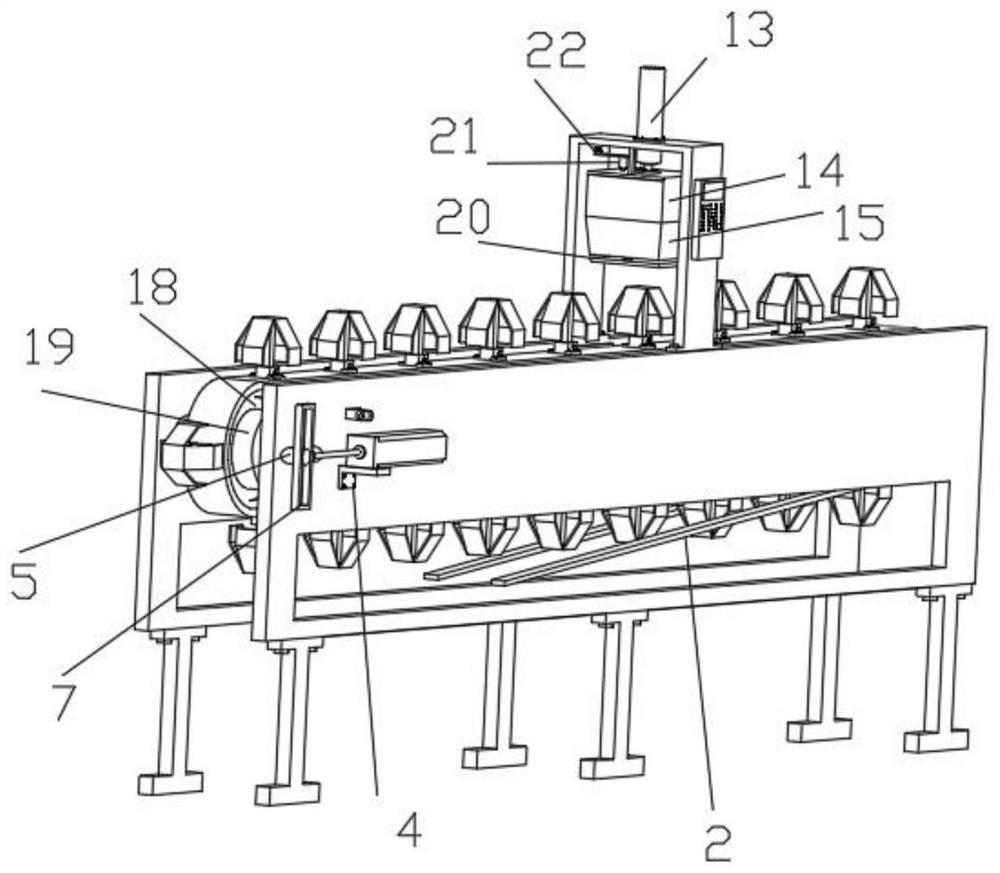

[0030] like figure 1 , 2 , 3, 4, 5, and 6, a shell cutting device for the production and processing of electrical connectors, including a support frame 1, the support frame 1 is connected with an intermittent movement structure for the intermittent movement of the shell, and the intermittent movement structure includes a first cylinder 3 , the first support seat 4, the square frame 5, the square frame 5, the conveyor belt 6, the Z-shaped shaft 7, the ring gear 18, the rotating roller 19 and the timing belt 23, the first support seat 4 is fixedly installed on the outer wall of the support frame 1, The top of the first support base 4 is fixedly connected with the first cylinder 3, the output end of the first cylinder 3 is fixedly connected with the square frame 5, and the inner wall of the support frame 1 is evenly and fixedly connected with the rotating roller 19 through the fixedly connected bearing, and the rotating roller 19 The outer wall is fixedly connected with a ring g...

Embodiment 2

[0036] Embodiment 2 is a further improvement to Embodiment 1.

[0037] like figure 1 , 3 As shown, the support frame 1 is also connected with an automatic control structure, the automatic control structure includes a first contact switch 8, a first mounting base 9, a second contact switch 21 and a second mounting base 22, the left side wall of the first mounting base 9 The first contact switch 8 is fixedly connected, and the first mount 9 is fixedly mounted on the side wall of the support frame 1, the second mount 22 is fixedly mounted on the top of the n-shaped plate 12, and the bottom of the second mount 22 is fixedly connected with The second contact switch 21, after the square frame 5 contacts the first contact switch 8, the controller 11 controls the first cylinder 3 to stop and the second cylinder 13 to start, and after the square cylinder 14 contacts the second contact switch 21, the controller 11 controls the first cylinder 3 to stop. Cylinder 3 starts and second cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com