Numerical control turning machining center based on flexible manufacturing

A flexible manufacturing and machining center technology, used in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as affecting the normal grinding of grinding components, inaccurate parts, and unable to rotate normally, to avoid jamming The effect of gap action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

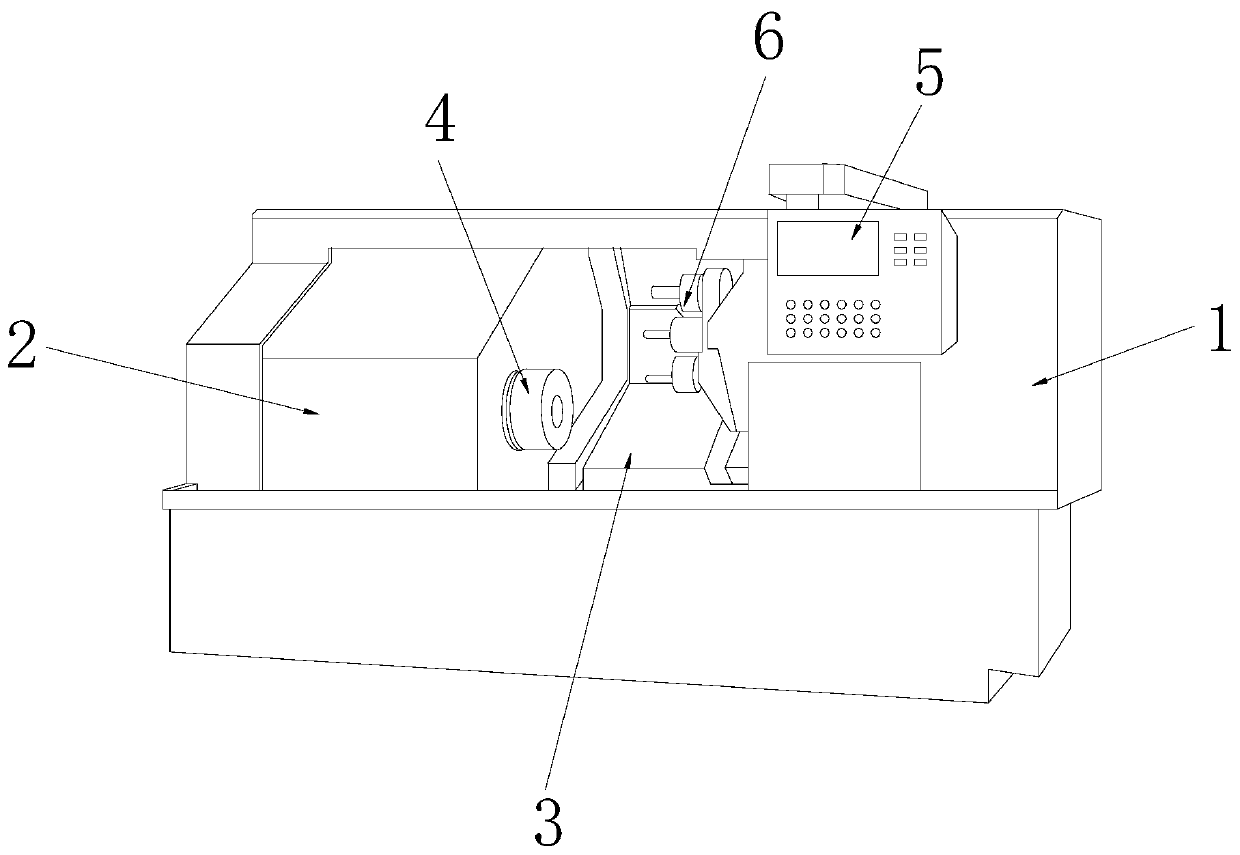

[0030] like Figure 1-Figure 5 As shown, the present invention provides a technical scheme based on flexible manufacturing of CNC turning machining center:

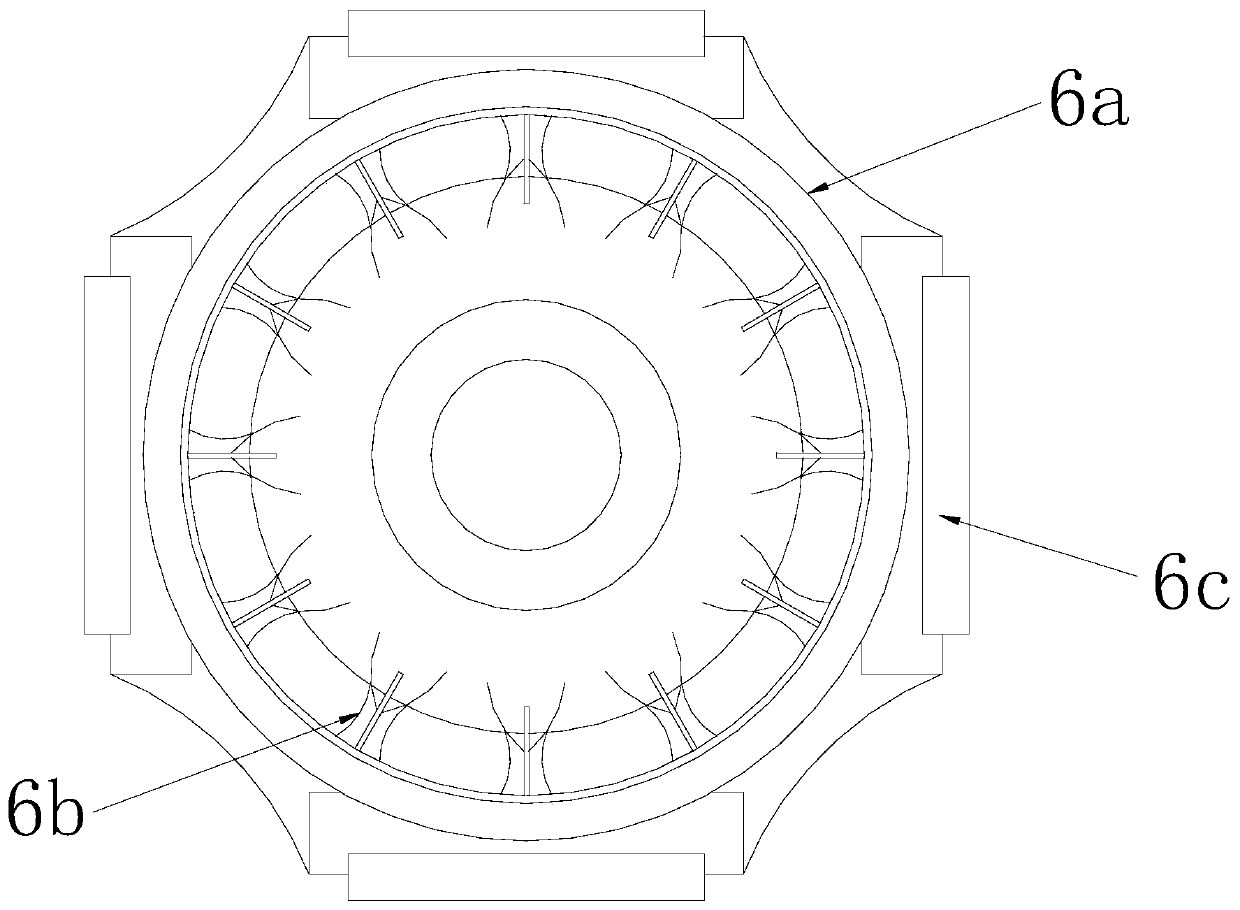

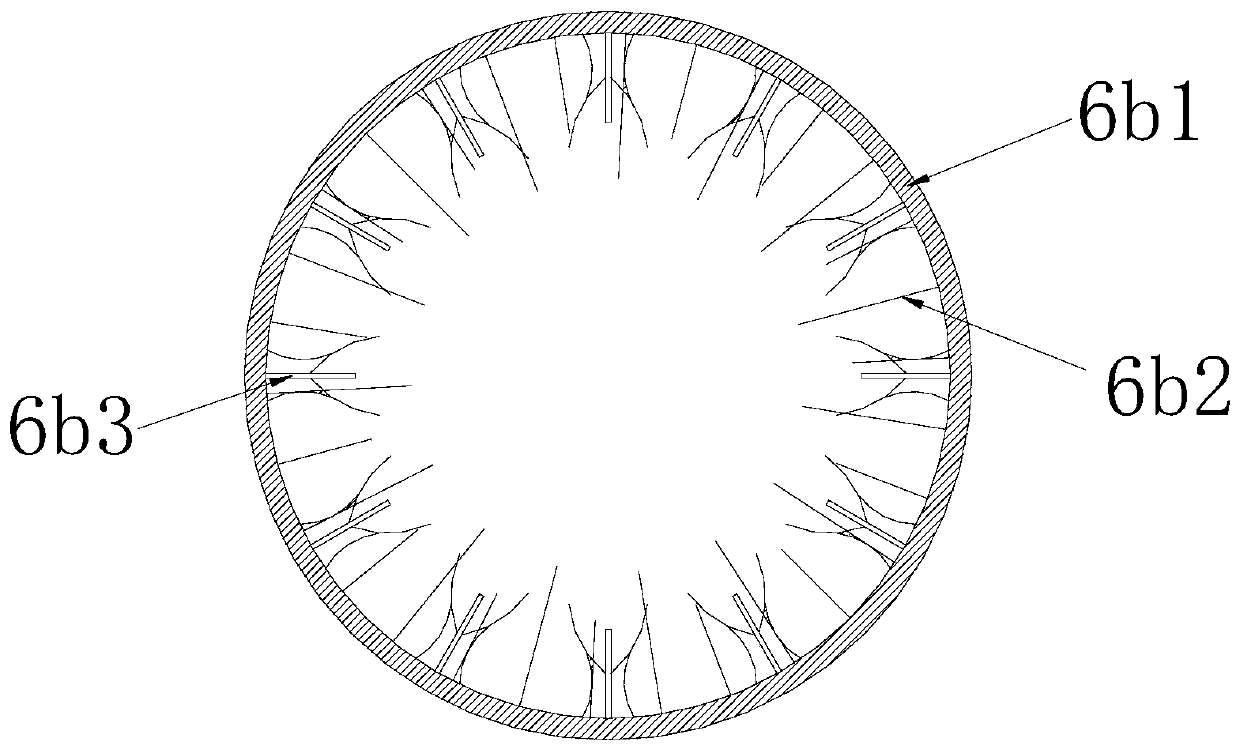

[0031] like Figure 1-Figure 2 As shown, a CNC turning machining center based on flexible manufacturing, its structure includes a device main body 1, a drive box 2, a workbench 3, an adapter plate 4, a controller 5, and a processing component 6, and the drive box 2 is installed on the device body The upper surface of 1 is connected by electric welding, the workbench 3 is installed in the middle of the upper surface of the equipment main body 1 and connected by electric welding, the connecting plate 4 is set on the left side of the middle of the drive box 2 and connected by electric welding, the control The device 5 is installed on the right side of the front surface of the drive box 2 and connected by electric welding. The processing assembly 6 is arranged on the left side of the middle part of the drive box 2 and connec...

no. 2 example

[0043] like figure 1 , figure 2 , Image 6 As shown, the present invention provides a technical scheme based on flexible manufacturing of CNC turning machining center:

[0044] like Figure 1-Figure 2 As shown, a CNC turning machining center based on flexible manufacturing, its structure includes a device main body 1, a drive box 2, a workbench 3, an adapter plate 4, a controller 5, and a processing component 6, and the drive box 2 is installed on the device body The upper surface of 1 is connected by electric welding, the workbench 3 is installed in the middle of the upper surface of the equipment main body 1 and connected by electric welding, the connecting plate 4 is set on the left side of the middle of the drive box 2 and connected by electric welding, the control The device 5 is installed on the right side of the front surface of the drive box 2 and connected by electric welding. The processing assembly 6 is arranged on the left side of the middle part of the drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com