Folding tent eave frame mechanism

A tent frame, tent technology, applied in tents/canopies, building types, buildings, etc., can solve problems such as inconvenience in unfolding or folding, and achieve the effect of stable, firm and reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

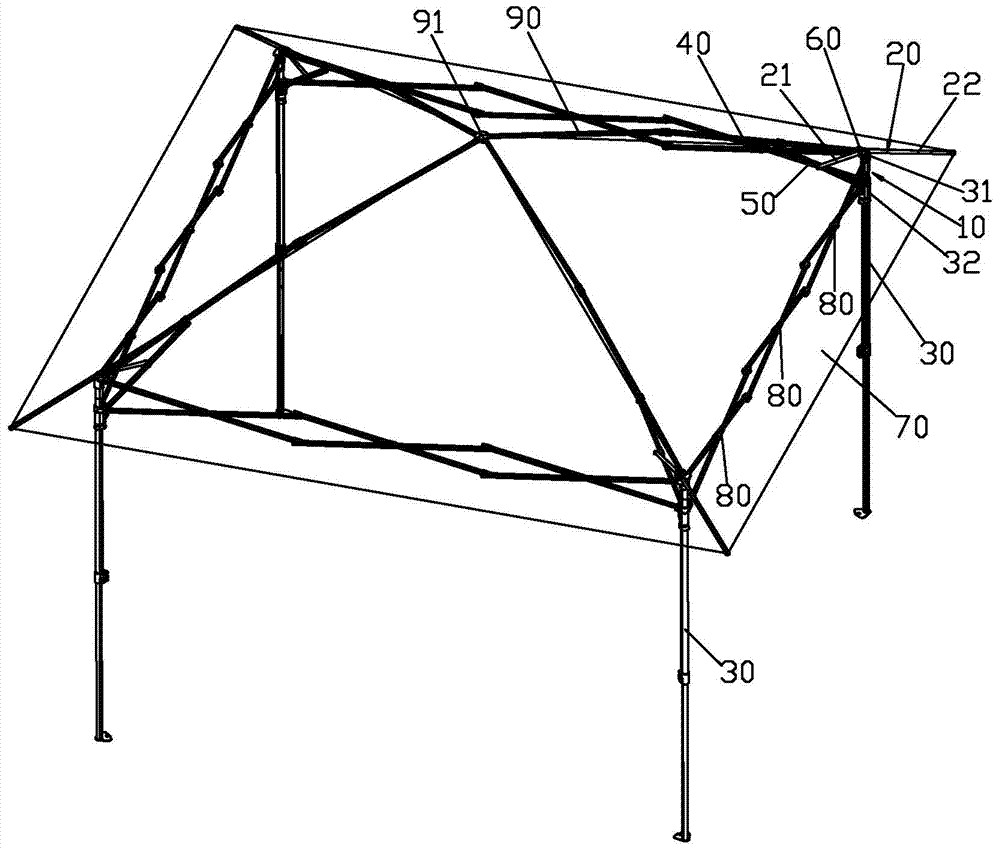

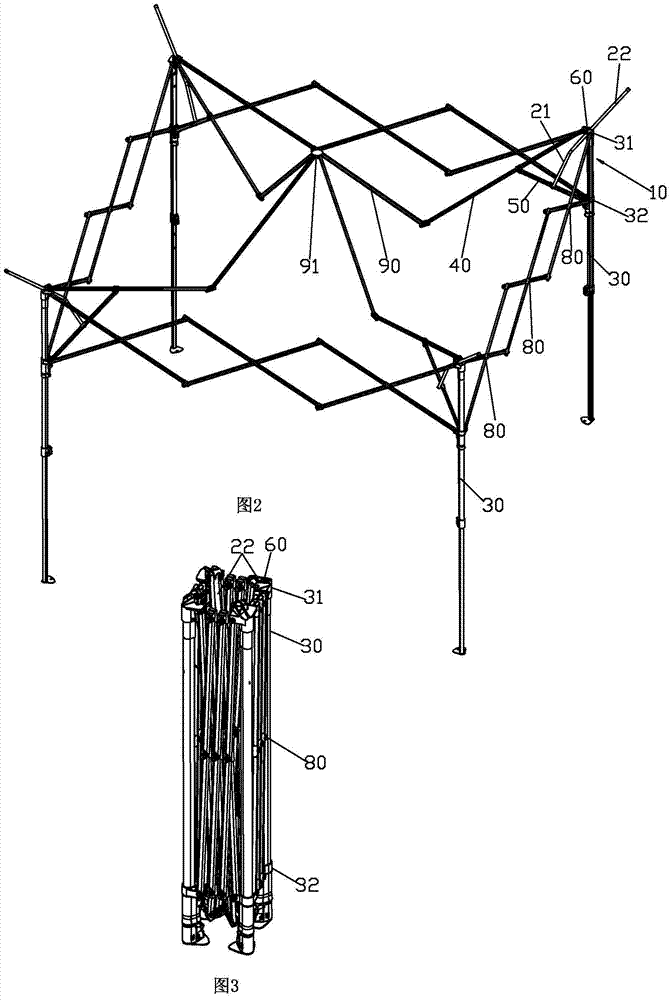

[0035] Please check Figure 4 , Figure 5 , Figure 6 and Figure 7 , a folding tent eave frame mechanism 10, comprising a tent frame and eave poles 20.

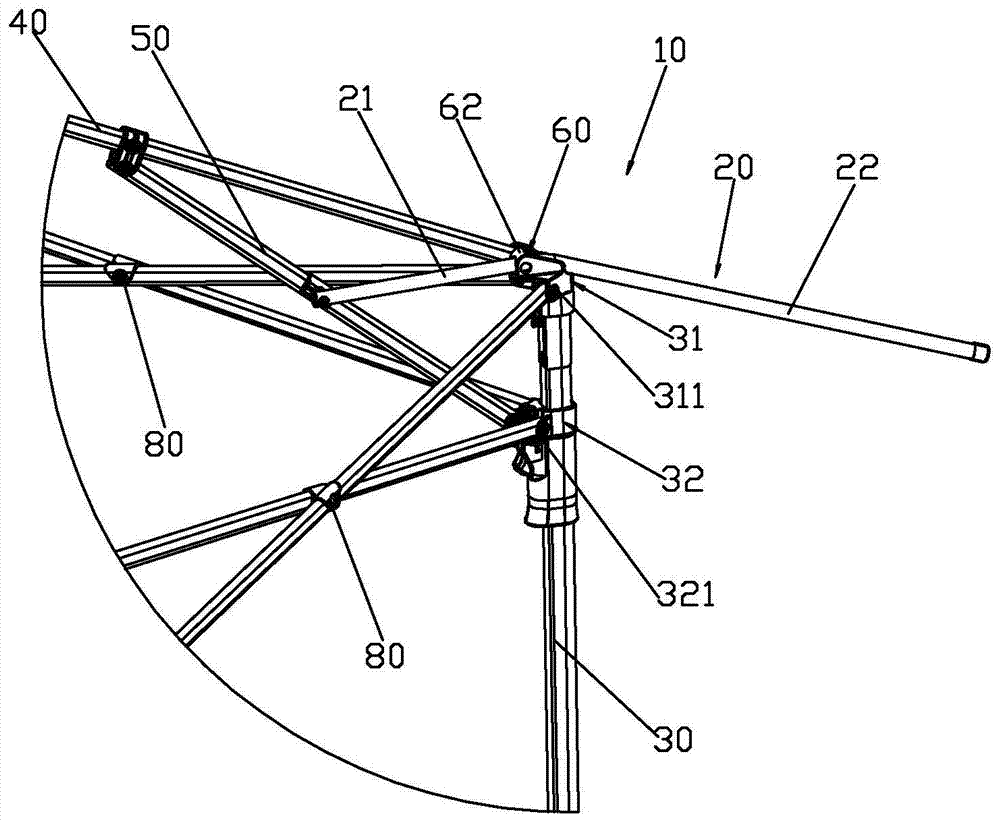

[0036] The tent frame includes a column 30, a tent pole 40 and an oblique pole 50, the top of the column 30 is fixed with a fixed seat 31, and the column 30 is slidably connected with a sliding seat 32 that can slide up and down along the column 30; the sliding seat 32 and A locking position is also provided between the uprights 30, and the locking position can keep the sliding seat 32 in a position so that the tent frame remains in an unfolded state. Of course, releasing the locking position can make the sliding seat 32 slide up and down along the uprights. The first end of the tent pole 40 is pivotally connected to the solid seat 31, the first end of the inclined pole 50 is pivotally connected to the slide seat 32, and the second end of the inclined pole 50 is pivotally connected to the middle part of the tent pole 40, ...

Embodiment 2

[0044] Please check Figure 8 , Figure 9 , Figure 10 and Figure 11 , it differs from Embodiment 1 in that: the eaves rack mechanism 10 also includes a pivotal seat 64, the pivotal seat 64 is pivotally connected to the fixed seat 31, the slideway 60 is arranged on the pivotal seat 64, and the eave rod The second straight section 22 of 20 is adapted to the slideway 60, and the relative movement between the slideway and the second straight section constitutes a translation structure. The angle between the first straight section and the second straight section corresponds to the slideway when the eave rod is deployed. The correspondence means that the angle just abuts against the pivot seat, and the angle is just close to the entrance of the slideway 60 . In this embodiment, the pivotal seat is pivotally connected to the solid seat, but it is not limited thereto. According to needs, it can also be pivotally connected to the part near the top of the column or to the part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com