Floating blind-mating flow connector

A connector and fluid technology, which is applied in the direction of connection with fluid cut-off device, pipe/pipe joint/pipe fitting, passing element, etc., to achieve the effect of good sealing effect, simple assembly process and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

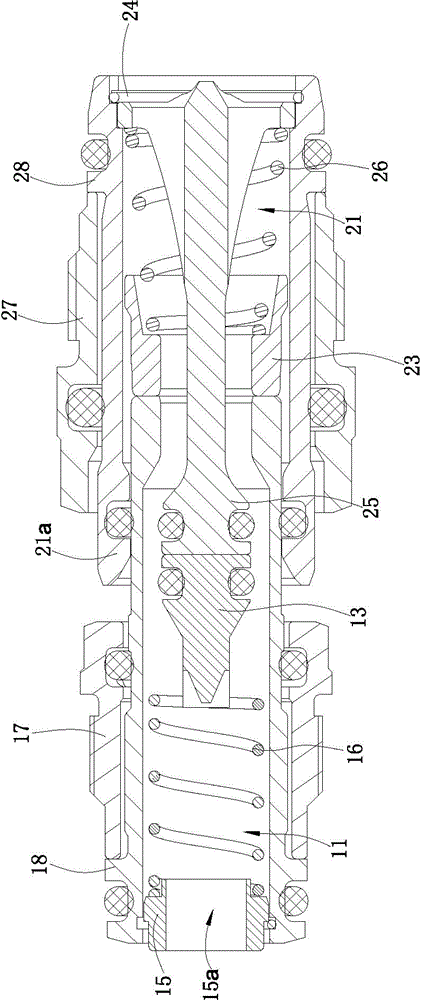

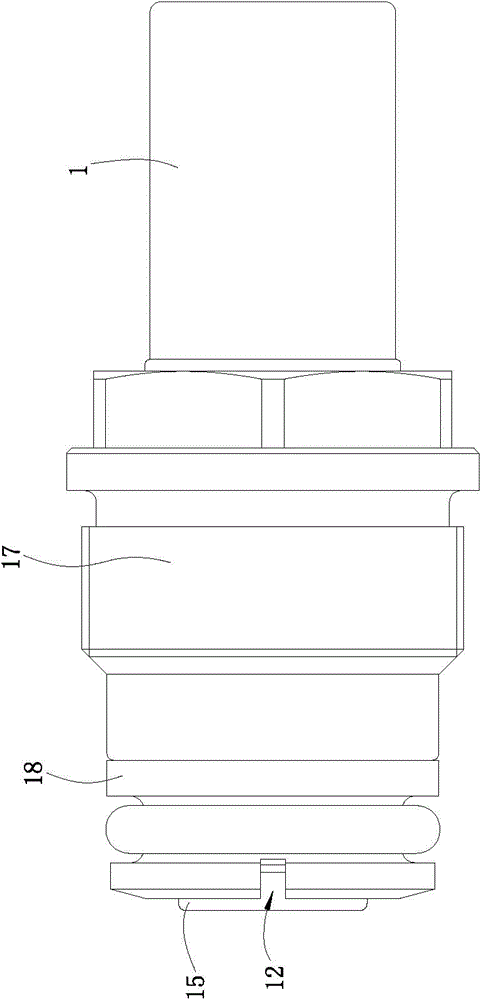

[0035] Such as figure 1 shown

[0036] The fluid connector includes a socket 2 and a plug 1 matched with the socket 2 .

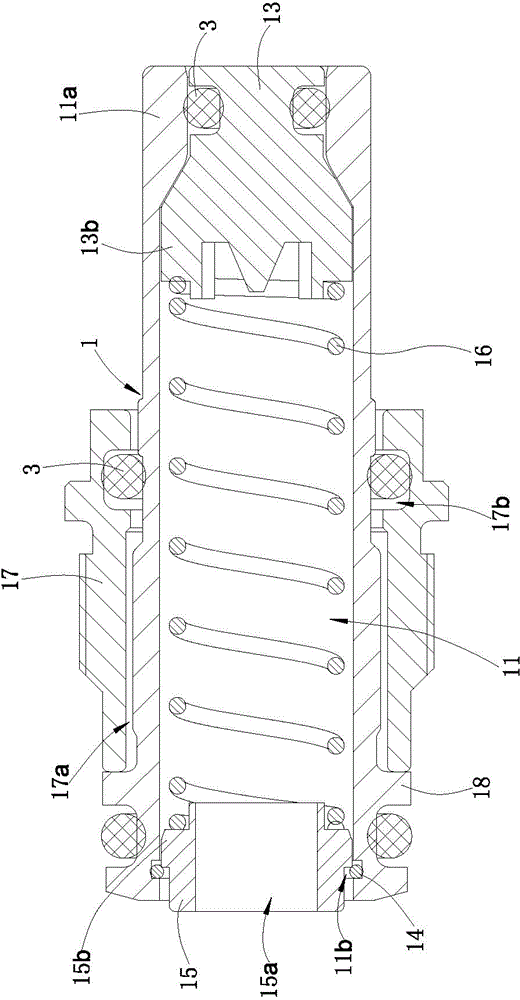

[0037] Such as Figures 2 to 6 shown

[0038] Inside the plug 1, there is a first guide hole 11 that runs through the front and rear end faces of the plug 1. The front end of the first guide hole 11 has a first inner convex ring 11a extending inward. The rear end side wall of the first guide hole 11 is provided There is a first snap ring groove 11b, the rear end surface of the plug 1 has a first disassembly notch 12, the first disassembly notch 12 extends to the first snap ring groove 11b, and the first guide hole 11 is provided with a first Snap ring 14, valve sleeve 15, first spring 16 and first valve core 13;

[0039] The front part of the first valve core 13 is sleeved in the first inner convex ring 11a, and the first valve core 13 has a first sealing ring groove 13a on the side wall of the front part, and a sealing ring is placed in the first seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com