High-safety car airbag in acceleration popping

An automotive safety and high-security technology, applied in vehicle safety arrangement, pedestrian/occupant safety arrangement, vehicle parts, etc. The probability of debris, the speed of ejection, and the effect of preventing airbag jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

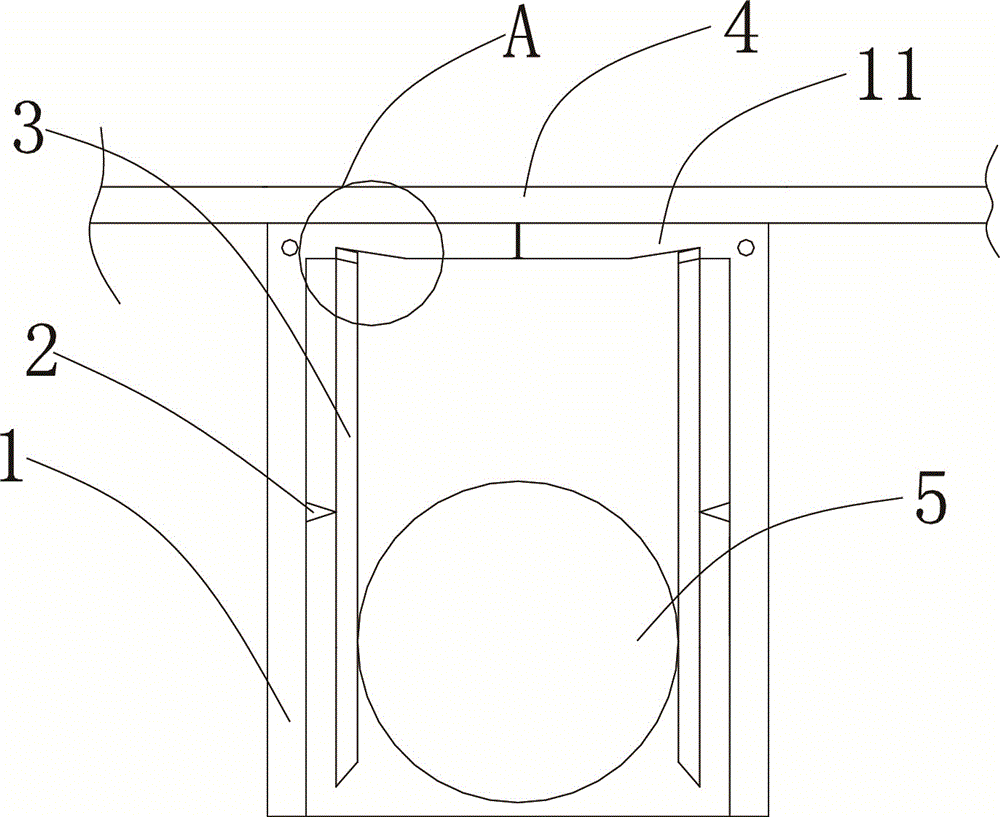

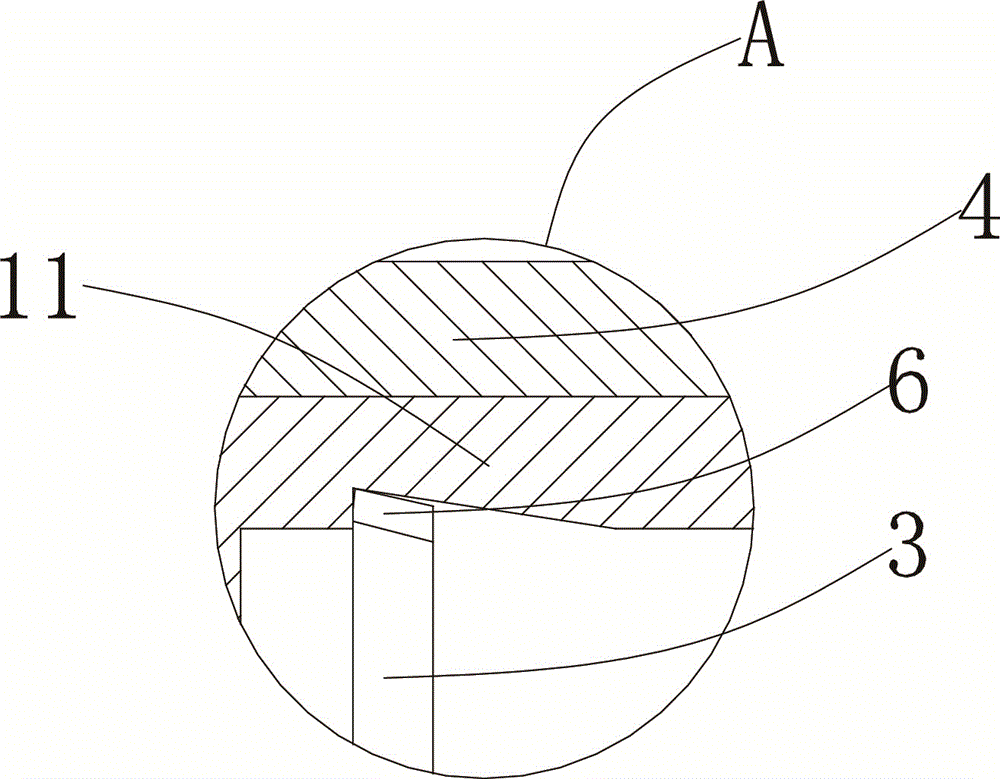

[0023] In embodiment 2, when the airbag 5 is inflated and expanded, the airbag 5 is positioned at the bottom of the airbag frame 1, and the airbag 5 first touches the horizontal bar of the L-shaped lever A3 at close range when the airbag 5 expands. The angle is 80 degrees. During the extrusion process, the overall rotation is 10 degrees, so that the end 6 of the lever A3 slides to the right. Since the inclination of the groove 11 gradually becomes shallower from the side to the central engraved line of the upper end cover, the end Part 6 slides to the right to jack up the upper end cover, the central engraved line is opened, and the engraved line of the car dashboard also has a preliminary opening tendency.

Embodiment 3

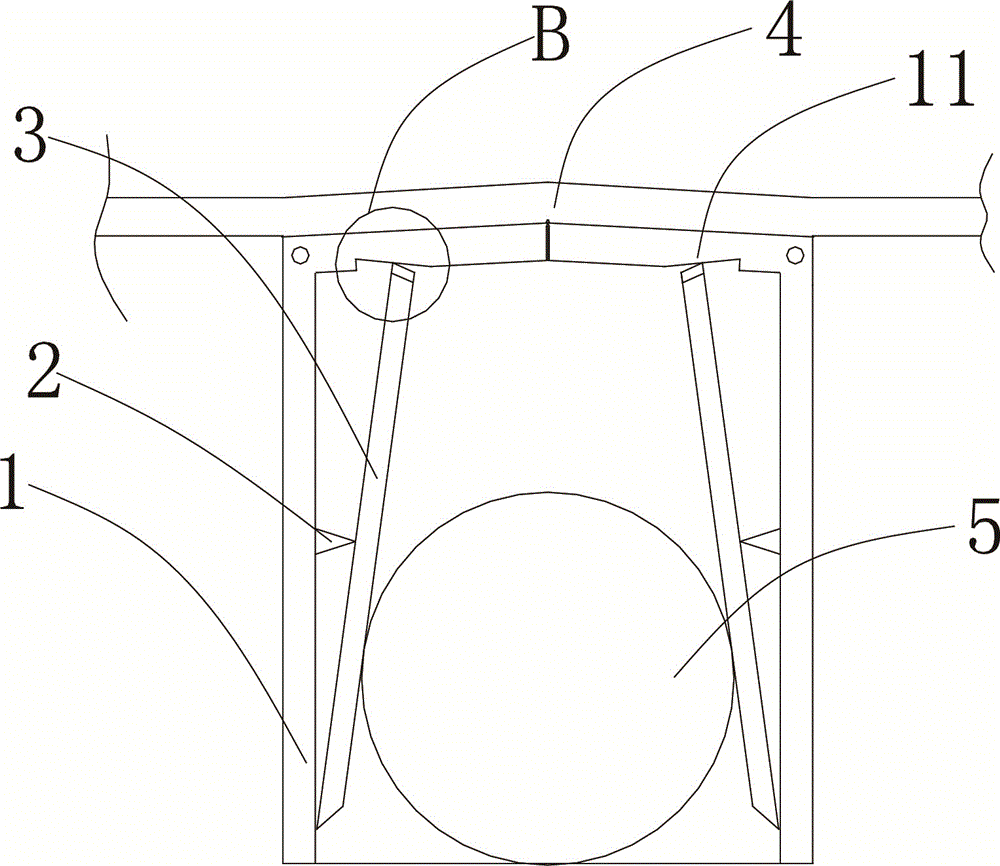

[0024] In Embodiment 3, when the airbag 5 is inflated and inflated, the airbag 5 is located at the bottom of the airbag frame 1. When the airbag 5 inflates, it first touches the inclined lever B31 at a close distance, so that the lever B31 is inclined by force after being stressed. It becomes horizontal, and the horizontal distance becomes longer. Apply force to the side of the lever A3 with the notch, so that the end 6 of the lever A3 slides to the right. Due to the inclination of the groove 11, the center line of the upper end cover is drawn from the side gradually become shallower, so the end 6 slides to the right to jack up the upper end cover, the central engraved line is opened, and the engraved line of the car dashboard also has a preliminary opening tendency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com