Stapling machine

A stapler and sheath technology, applied in the field of staplers, can solve problems such as damage, too fast, too strong, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

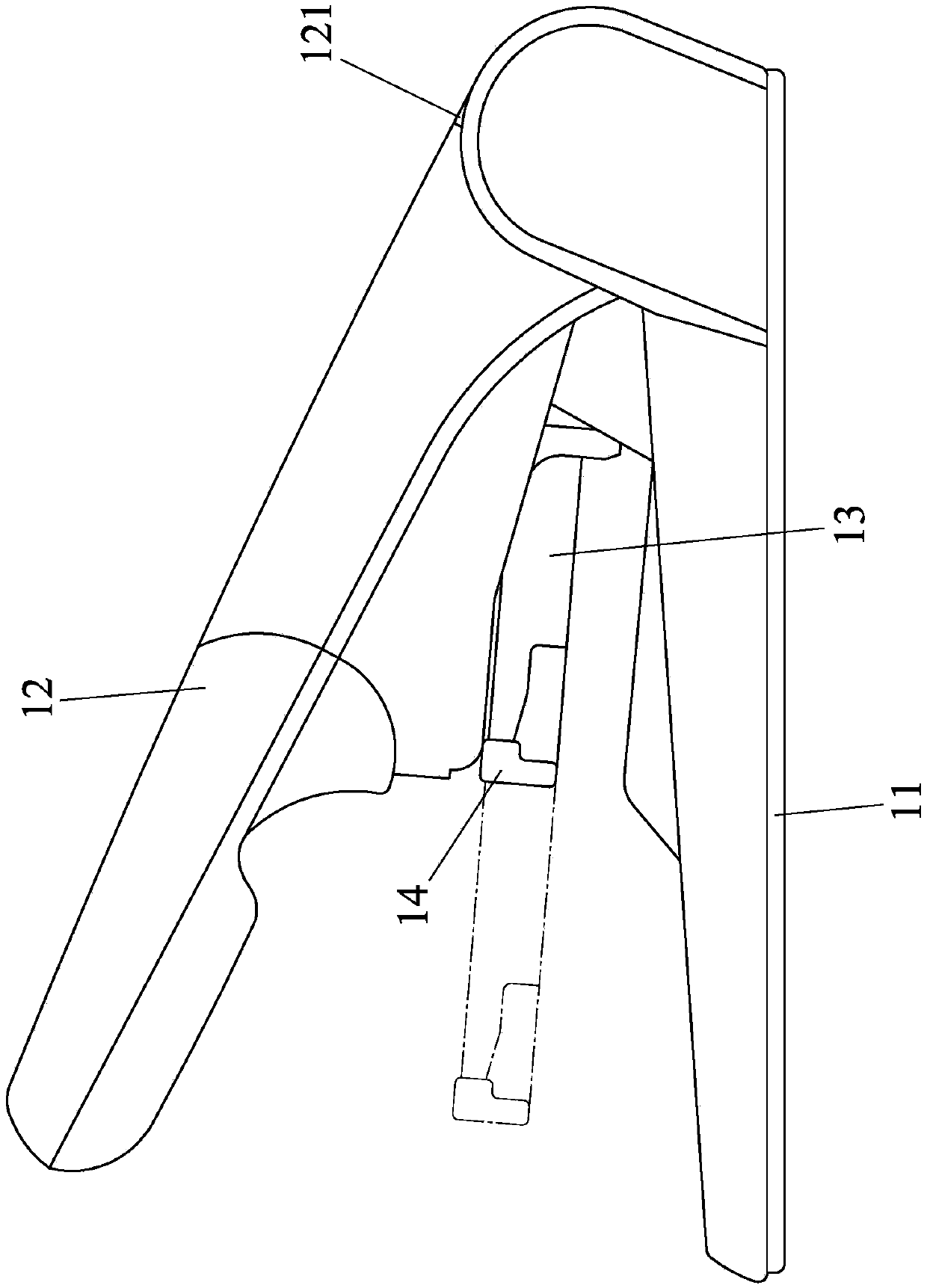

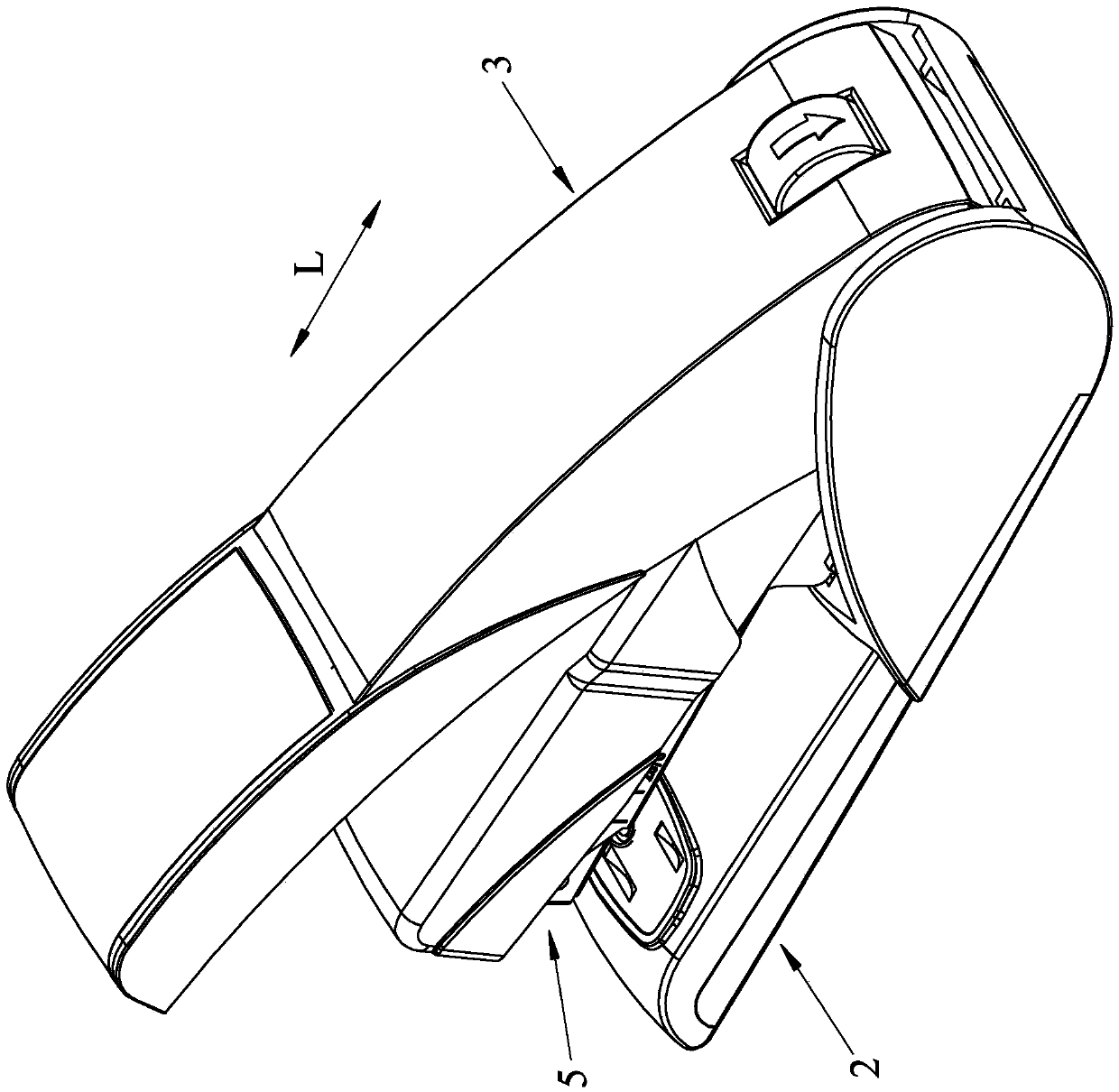

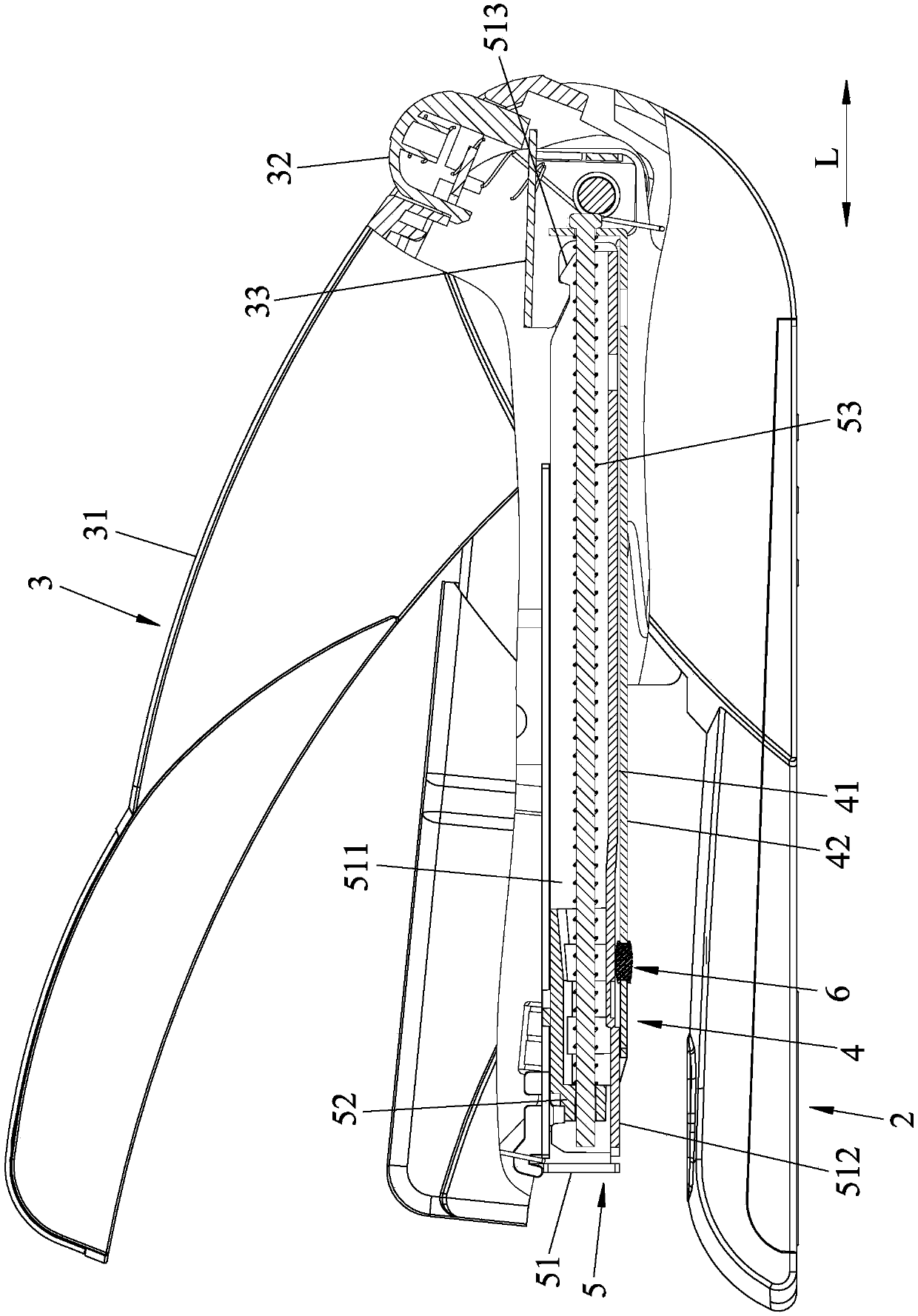

[0032] refer to figure 2 and image 3 , a first embodiment of the stapler of the present invention, defined image 3 The center left is a front, and defines image 3 The middle right is a rear opposite to the front, and the first embodiment includes a base 2 , a handle module 3 , a sheath 4 , a middle branch module 5 , and a buffer elastic member 6 .

[0033] The handle module 3 includes a handle 31 , a pressing member 32 disposed on the handle 31 , and a positioning member 33 that is abutted against by the pressing member 32 and rotates.

[0034] refer to image 3 , Figure 4 and Figure 5 , the sheath 4 extends along a front-rear direction L and is pivotally mounted on the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com