Composite type pavement structure and pavement method thereof

A composite and pavement technology, which is applied to cohesive pavement paved on site, bridge parts, roads, etc., can solve problems such as easy peeling of the waterproof adhesive layer, shorten the service life of the pavement, and weaken the strength of the underlying layer. Improve the anti-fatigue and anti-reflection crack performance, improve the stiffness of the bridge deck, and reduce the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Composite Pavement Structure and Construction Technology of Sliding Connection on Old Cement Concrete Pavement

[0048] (1) Structure and material

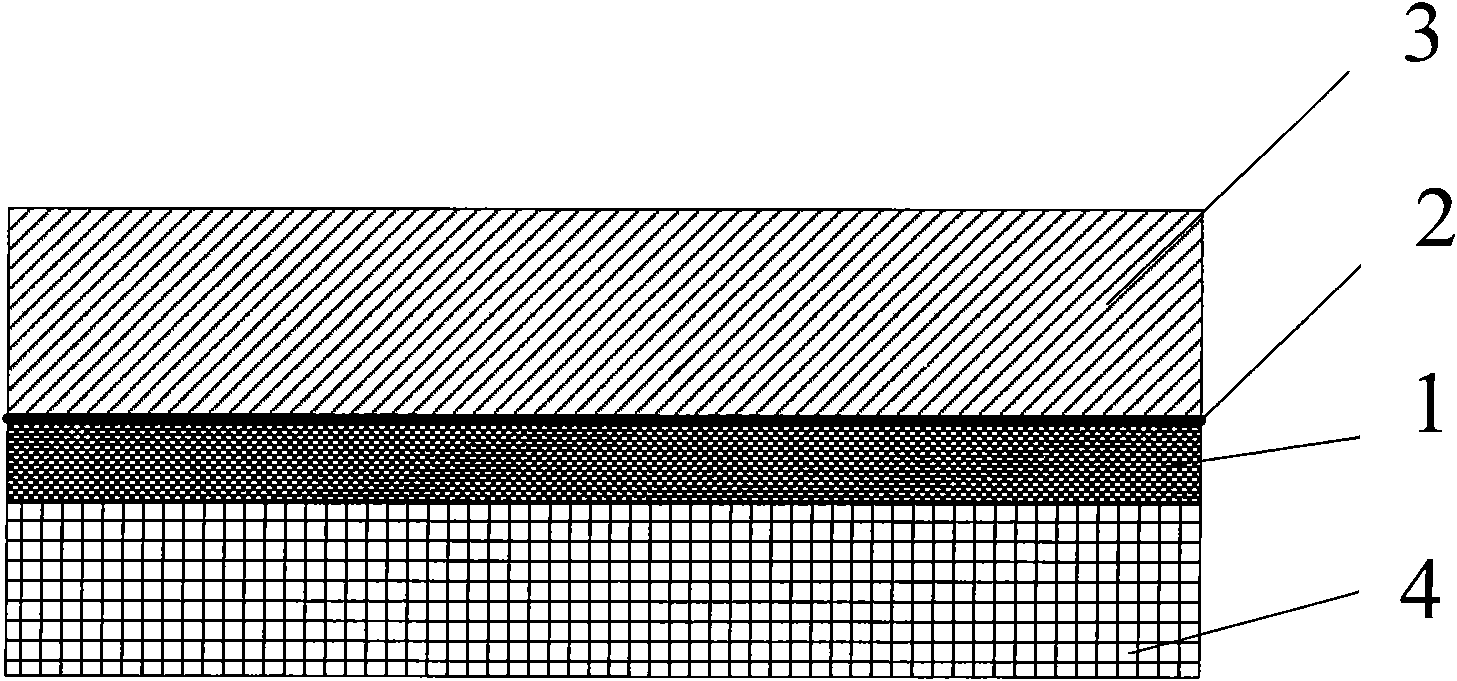

[0049] use figure 1 The pavement structure shown includes a base plate 1 , an adhesive layer 2 on the plate and an asphalt surface layer 3 from bottom to top.

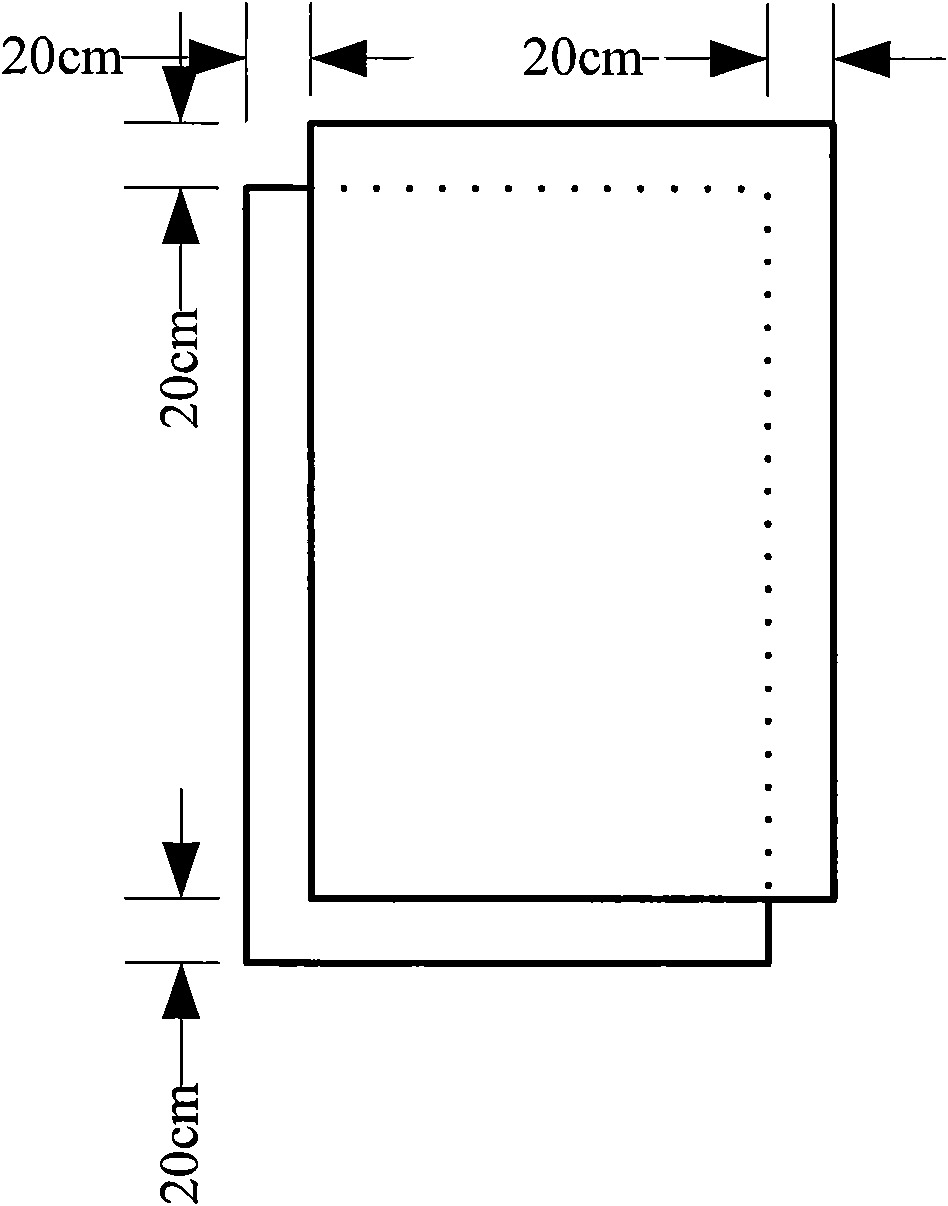

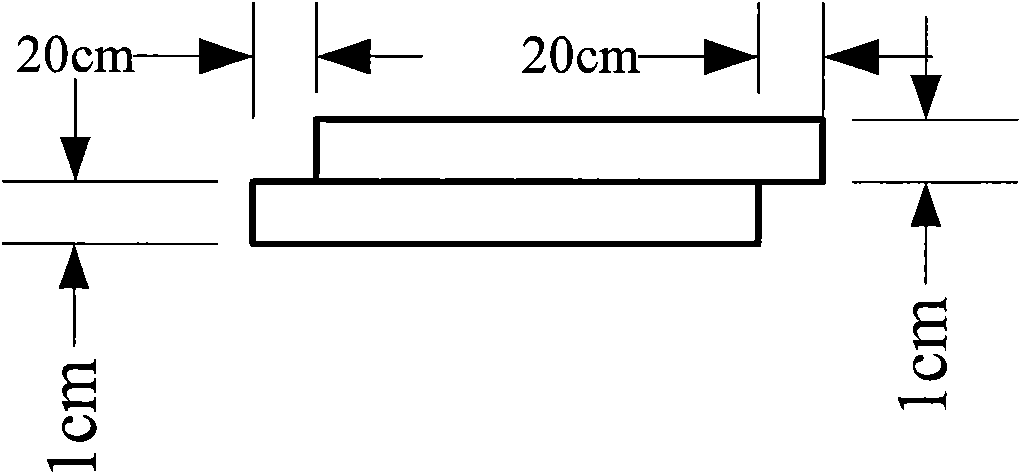

[0050] Substrate 1 uses a glass steel plate with a thermal expansion coefficient close to that of cement concrete; the technical specifications of the substrate of fiber-reinforced composite materials are shown in Table 1, as shown in figure 2 , image 3 As shown, the substrate 1 is an integrated structure, and the shape of the substrate 1 is that two overlapping cuboids are staggered in parallel along the contact surface, and the original overlapping sides are all staggered by the same distance, and the distance is 20 cm. The thickness of the substrate is 20mm; the length of each board is 30m and the width is 3.75m;

[0051] The sticky layer on the board adopt...

Embodiment 2

[0066] Composite pavement structure bonded to steel bridge deck with epoxy resin and its construction technology

[0067] (1) Structure and material

[0068] use Figure 5 The pavement structure shown is composed of a base plate 1 , an adhesive layer 2 on the upper plate, an adhesive layer 7 under the plate and an asphalt surface layer 3 . The substrate adopts a glass steel plate with a thermal expansion coefficient close to that of the steel plate. See Table 1 for technical indicators. Such as figure 2 , image 3 As shown, the substrate 1 is an integrated structure, and the shape of the substrate 1 is that two overlapping cuboids are staggered in parallel along the contact surface, and the original overlapping sides are all staggered by the same distance, and the distance is 20 cm. The thickness of the substrate is 20mm; the length of each board is 30m and the width is 3.75m.

[0069] The sticky layer on the board adopts a sprinkling amount of 2.0kg / m 2 SBS modified a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com