H-shaped support pile and preparation method thereof

A technology for supporting piles and a manufacturing method, which is applied to sheet pile walls, buildings, infrastructure engineering, etc., can solve the problems of uneven stress, environmental pollution by construction mud, low production efficiency, etc., so as to improve production efficiency and reduce anchorage. The effect of high process and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described in detail below through examples, but the present invention is not limited only to the following examples.

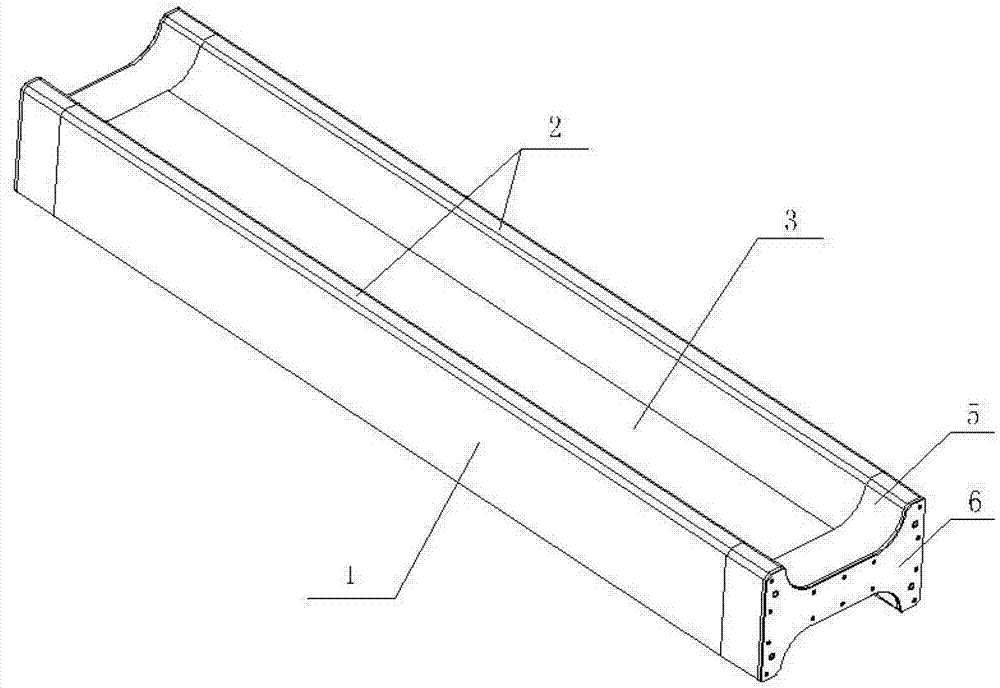

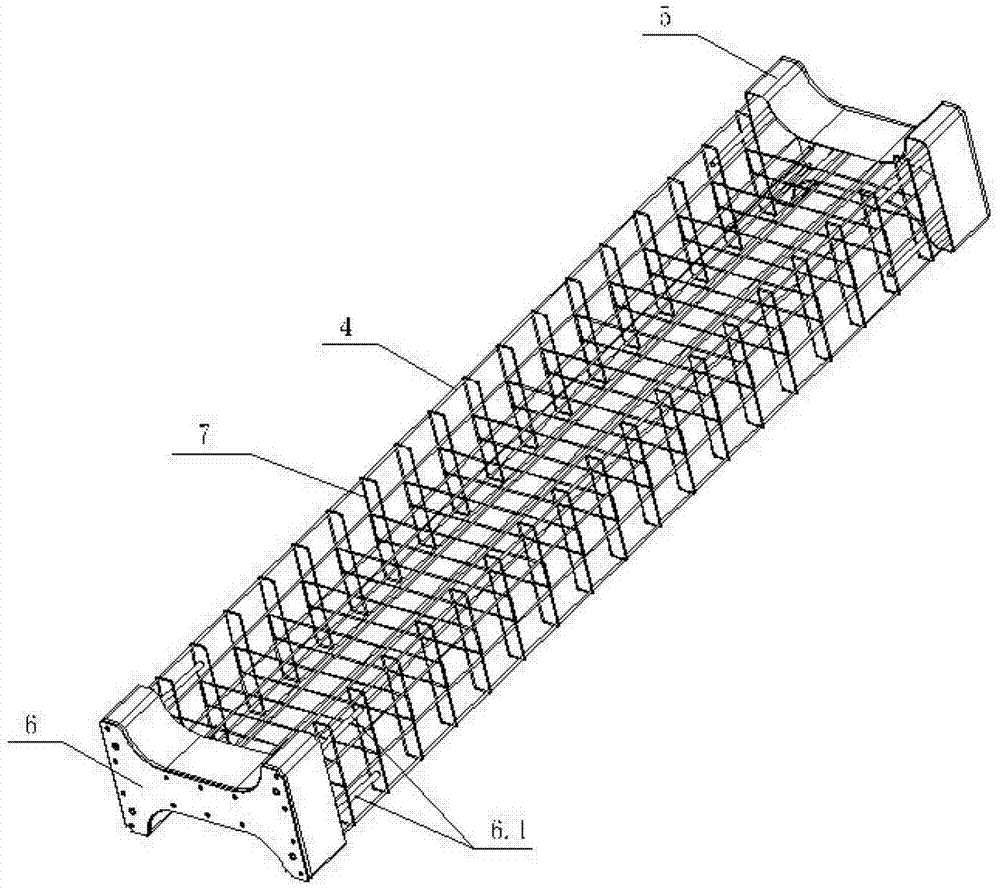

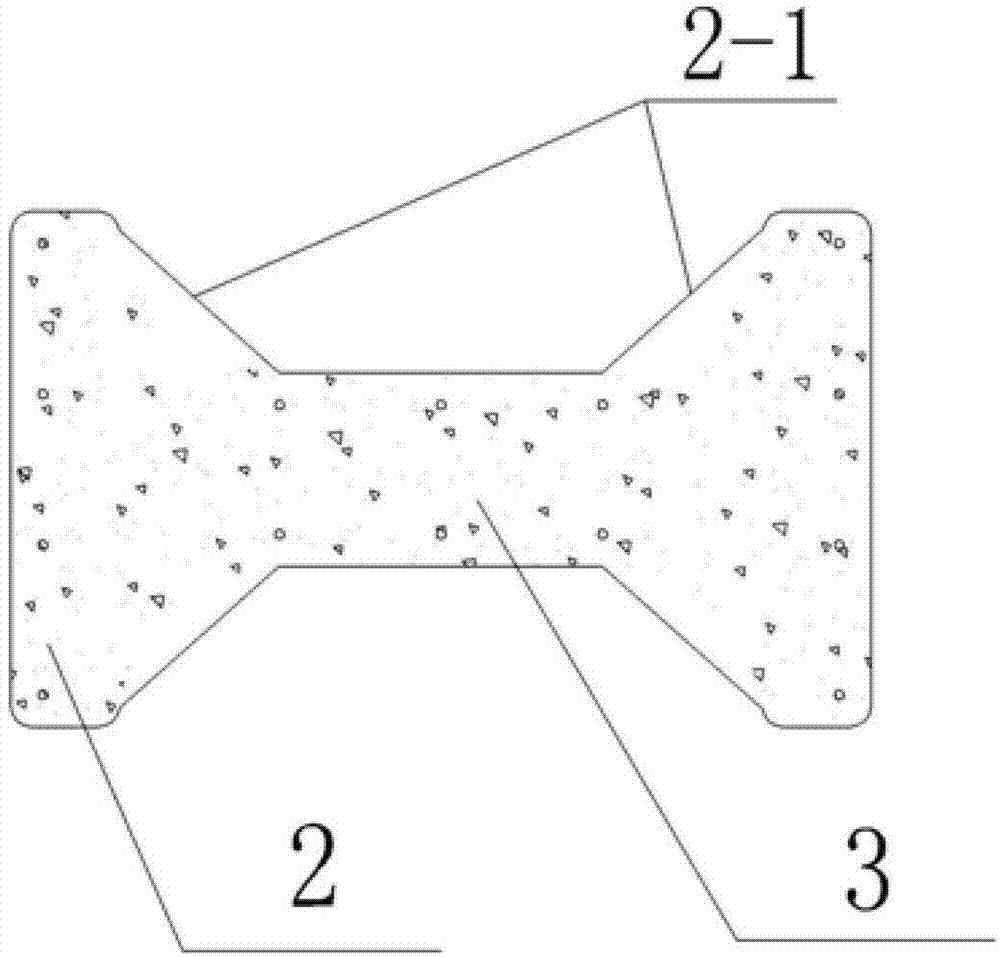

[0037] Such as Figure 1-5 As shown, a kind of H-shaped support pile of the present invention comprises a support pile body 1 formed by prestressed steel bars 4, stirrups 7 and concrete pouring, and is characterized in that: the cross section of the support pile body 1 It is an H shape consisting of two flanges 2 and a web 3 connected between the two flanges; at least one end of the support pile body 1 is provided with an end plate 6 and a pile collar 5, and the end plate 6 It is arranged on the end surface of the support pile body 1, and the end plate 6 is provided with a hole, and the prestressed steel bar 4 is placed in the hole; the pile hoop 5 is fixedly connected with the end plate 6 (welding can be used) Or it is integrally formed and fitted on the end of the support pile body 1, and the pile hoop 5 or the end pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com