Bayonet connection type fluid connector

A bayonet connection and connector technology, which is applied to connections with fluid cut-off devices, couplings, pipes/pipe joints/pipe fittings, etc., to achieve simple assembly procedures, fast positioning, and good sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

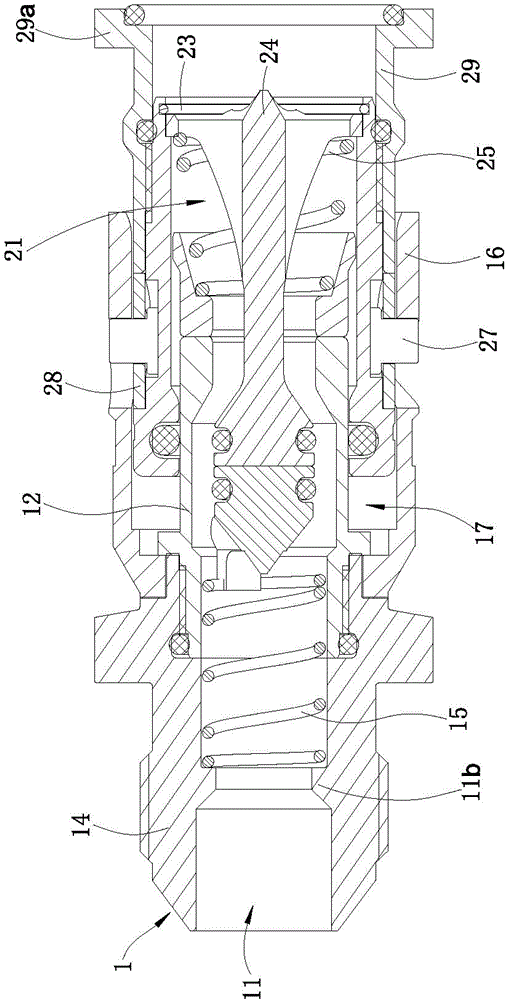

[0038] Such as figure 1 shown

[0039] The fluid connector includes a socket 2 and a plug 1 matched with the socket 2 .

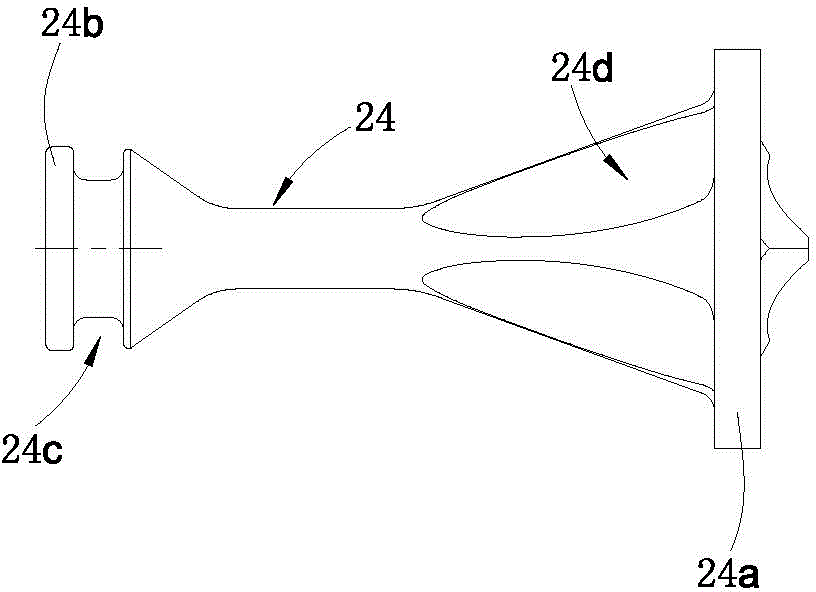

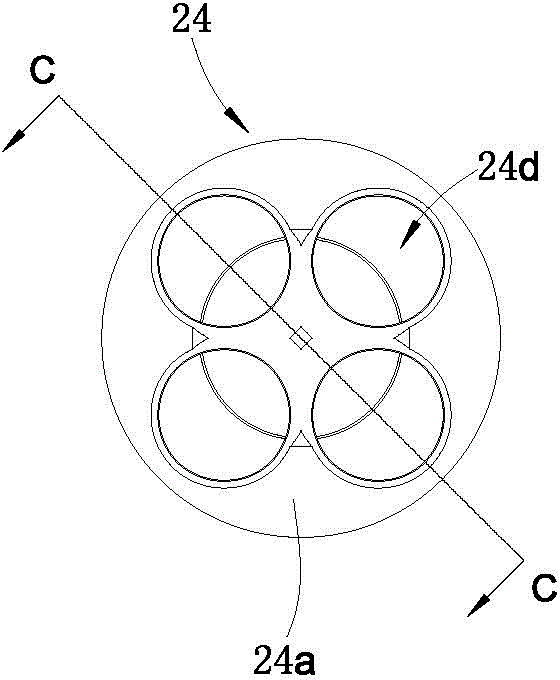

[0040] Such as Figures 2 to 6 shown

[0041] The plug 1 includes a valve body 12 at the front and a housing 14 at the rear. The valve body 12 and the housing 14 are fixed by threaded connections. The plug 1 has a valve body that runs through the front end of the valve body 12 and the rear end of the housing 14. The first diversion hole 11, the front end of the first diversion hole 11 has a first inner convex ring 11a extending inward, the rear side wall of the first diversion hole 11 has a first shoulder 11b extending inward, the first A first spring 15 and a first spool 13 are arranged in the diversion hole 11;

[0042] The front part of the first valve core 13 is sleeved in the first inner convex ring 11a, and the first valve core 13 has a first sealing ring groove 13a on the front side wall, and a sealing ring is placed in the first sealing ring gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com