Electronic product recycling device

A technology for recycling and electronic products, applied in grain processing, non-rotational vibration suppression, etc., can solve problems such as energy waste, high device load, and difficult crushing, achieve good crushing effect, reduce separation costs, and reduce workpiece loss and the effect on energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

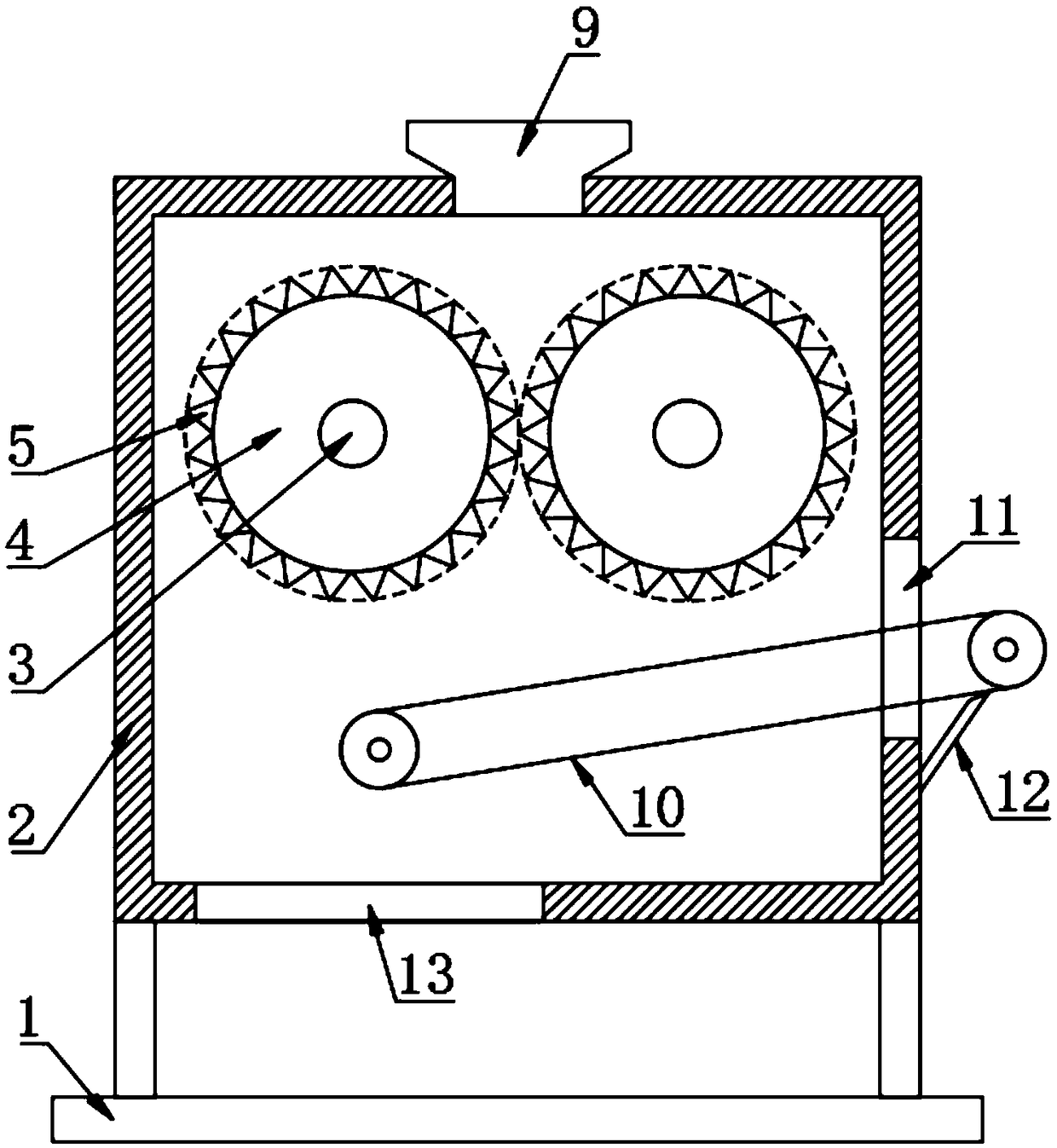

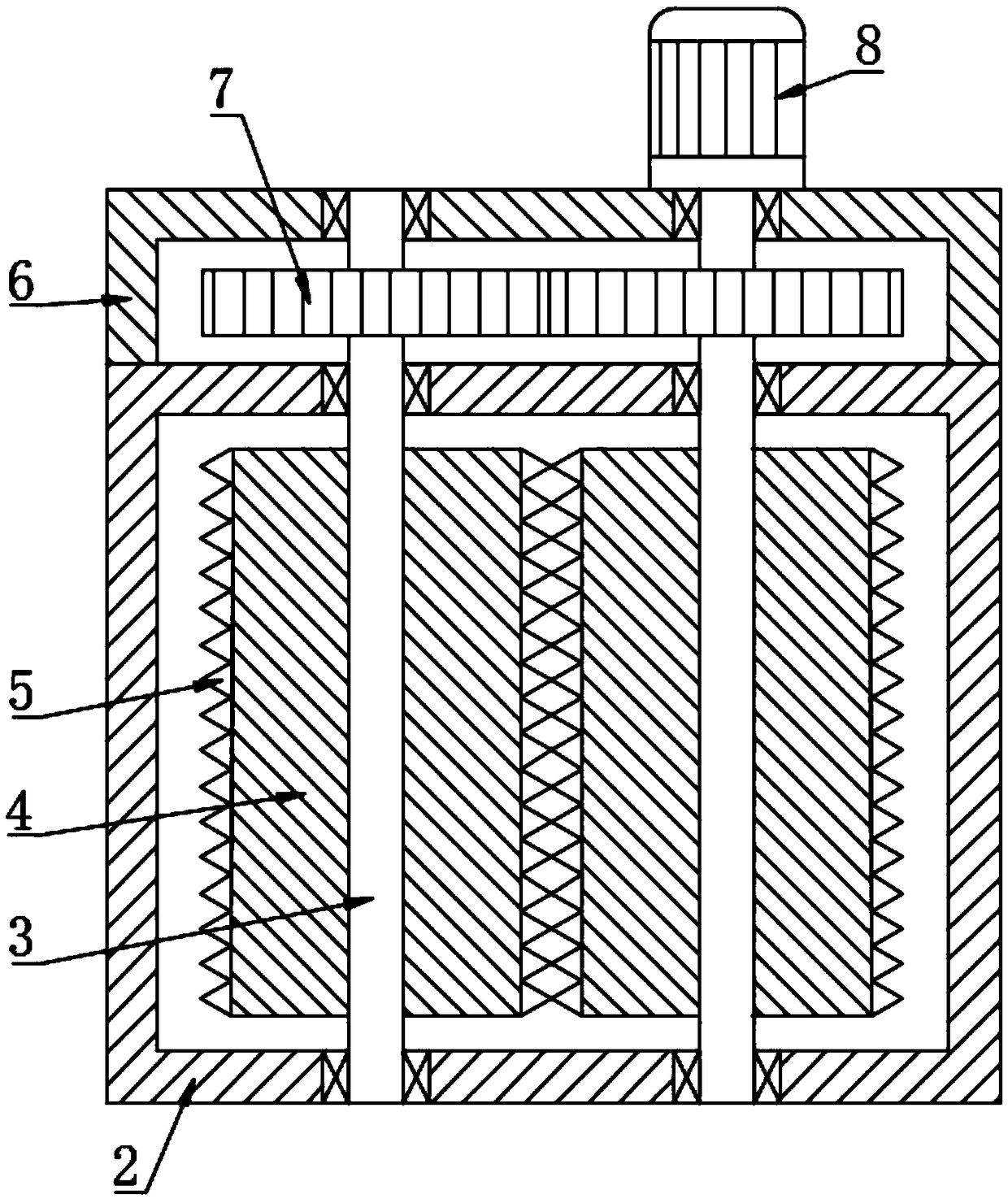

[0021] see Figure 1~2 , an electronic product recovery processing device, comprising a base 1, the top of the base 1 is fixed with a crushing box 2 through a bracket; the top of the crushing box 2 is provided with a feeding hopper 9; There are two left and right rotating shafts 3, and the left and right rotating shafts 3 are respectively connected to the front and rear walls of the crushing box 2 in rotation. The left and right rotating shafts 3 are located in the inner part of the crushing box 2 and are fixedly equipped with crushing rollers 4. The side walls of the crushing rollers 4 are evenly equipped with a number of crushing teeth 5, so that Improve the crushing effect; the rear wall of the crushing box 2 is fixedly equipped with a gear box 6, the rear end of the rotating shaft 3 passes through the rear wall of the gear box 6 and is rotationally connected with the rear wall of the gear box 6, and the left and right rotating shafts 3 are fixed in the gear box 6 Gears 7 m...

Embodiment 2

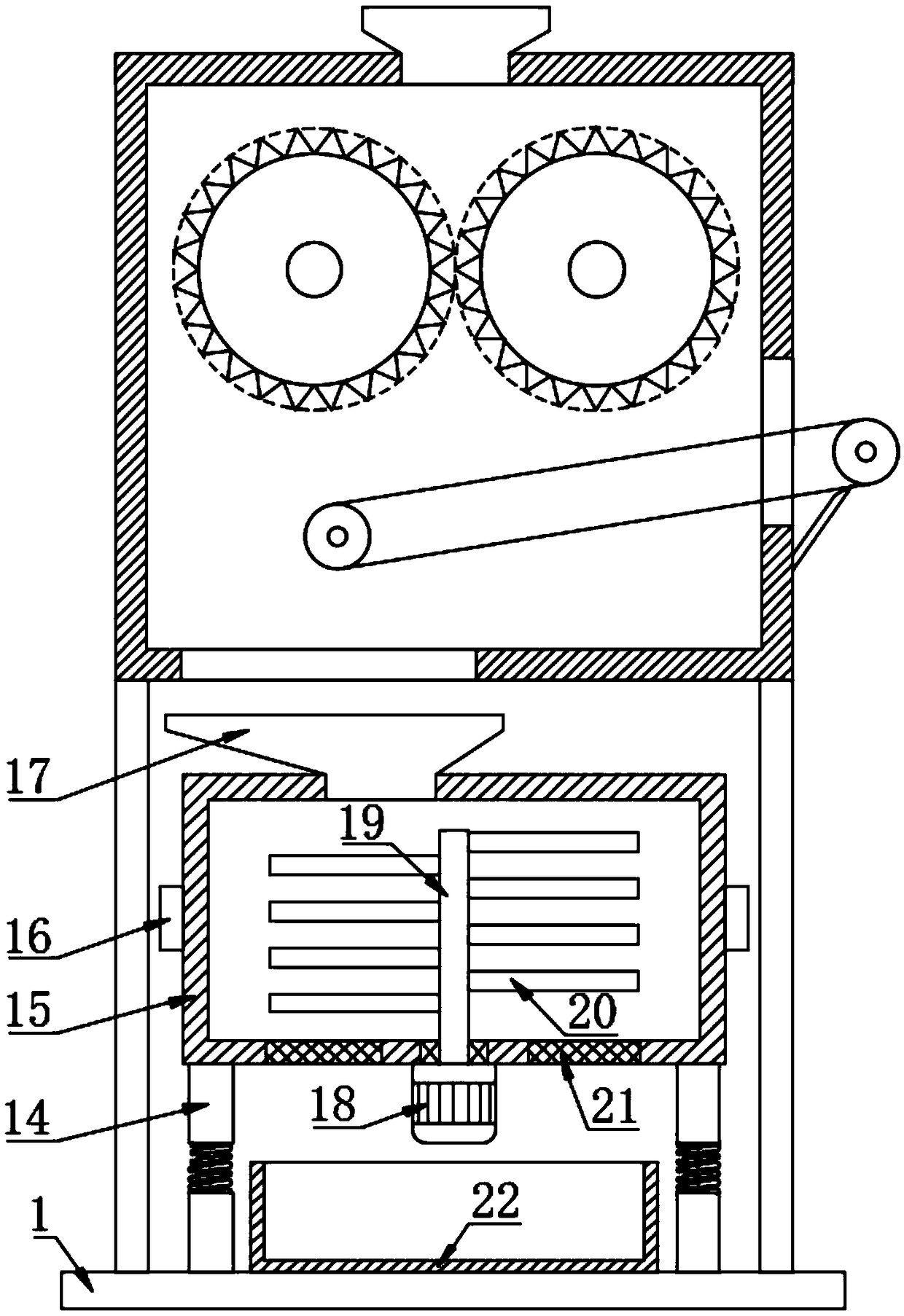

[0023] see image 3 , on the basis of embodiment 1, a crushing barrel 15 is also provided above the base 1, and the crushing barrel 15 is located below the crushing box 2. The bottom of the crushing barrel 15 is fixedly connected with a pole 14, and the bottom end of the pole 14 is connected to the base 1 fixedly connected, the pole 14 includes three sections, the upper and lower sections are round rods, the middle section is a spring, and the upper and lower ends of the spring are fixedly connected with the upper and lower round rods respectively, so that the crushing bucket 15 can vibrate; the crushing bucket 15 The top is fixedly connected with a hopper 17, the hopper 17 is located below the discharge port 13, the non-magnetic material falls into the crushing bucket 15 through the hopper 17, and the bottom wall of the crushing bucket 15 is rotatably connected with a second rotating shaft 19 through a sealed bearing. A number of crushing blades 20 are fixedly installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com