Reinforced concrete crusher

A reinforced concrete and pulverizer technology, applied in mechanical equipment, using liquid separating agent, solid separation and other directions, can solve the problems of time-consuming and laborious recycling of steel bars, easy occurrence of a large amount of dust, inconvenience in recycling steel bars, etc. The effect of improving the crushing effect and crushing efficiency, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

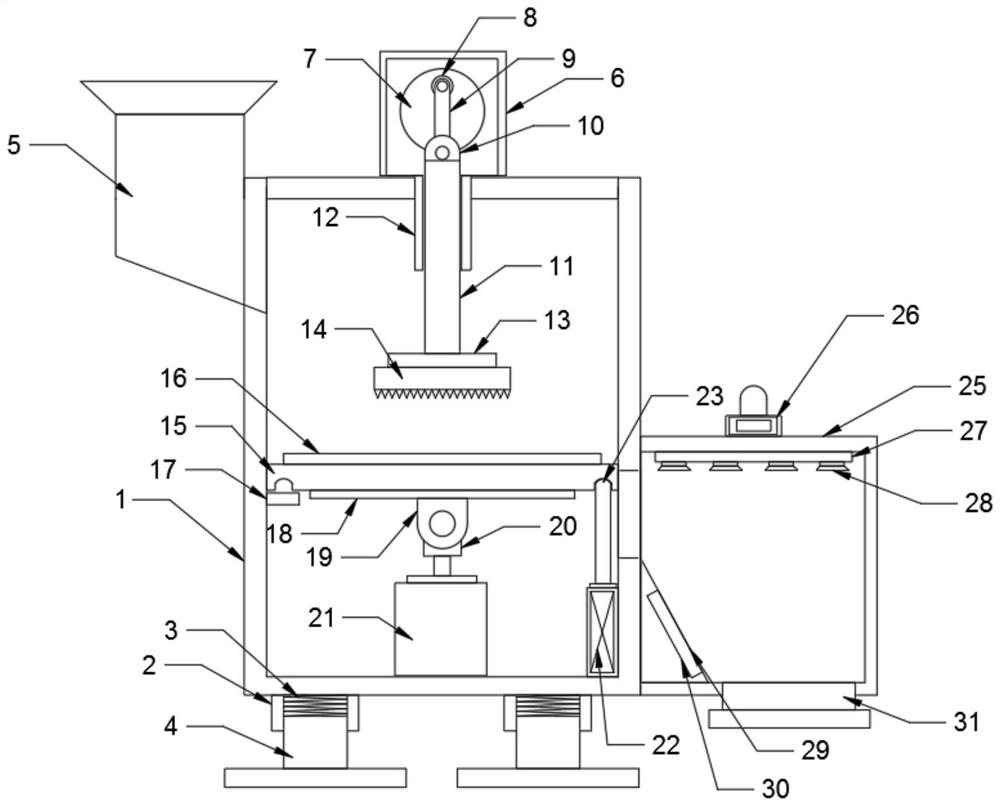

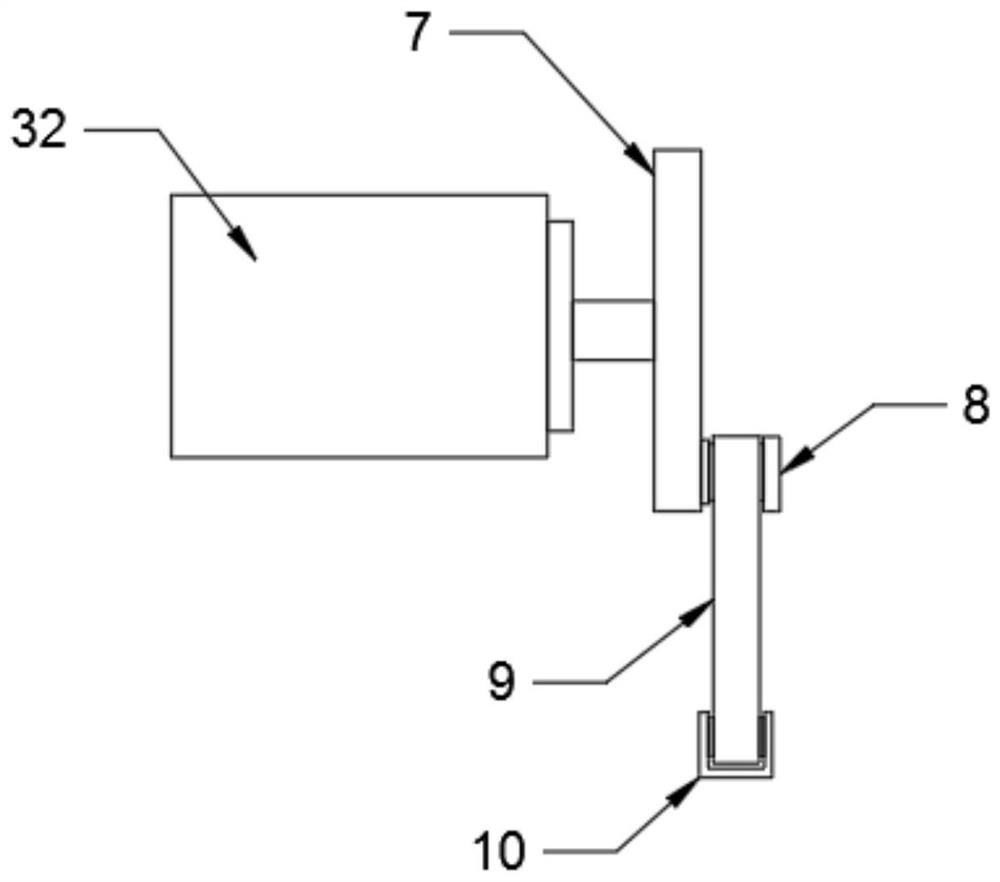

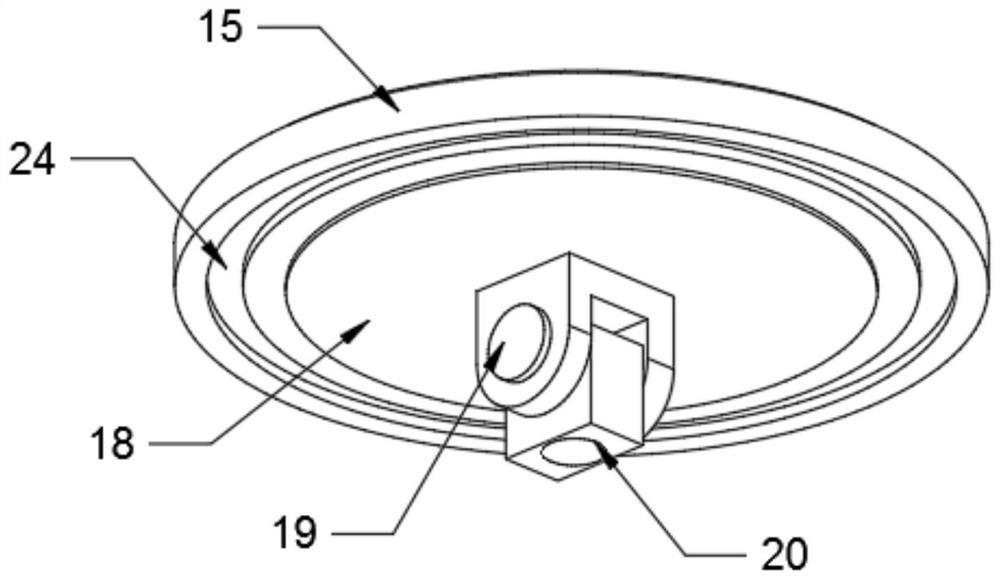

[0022] see Figure 1~3 , in an embodiment of the present invention, a pulverizer for reinforced concrete includes a crushing box 1, a discharge box 25 and a crushing hammer 14, a cylinder 2 is installed at the bottom of the crushing box 1, and a spring 3 is installed inside the cylinder 2 , the base 4 is installed at the bottom of the spring 3, and there are four cylinders 2, springs 3 and base 4, which are divided into four groups and evenly distributed at the four corners of the bottom of the crushing box 1. The cylinder 2, spring 3 and base 4 , can effectively slow down the vibration of the crushing box 1, and improve the service life of the crushing box 1; the upper left side of the crushing box 1 is provided with a feed port 5, and a motor frame 6 is installed in the middle of the top of the crushing box 1, and a second motor frame is installed inside the motor frame 6. Motor 32, rotating disk 7 is installed on the front end of second motor 32 rotating shafts, and rotatin...

Embodiment 2

[0026] see Figure 4 , in an embodiment of the present invention, a pulverizer for reinforced concrete includes a crushing box 1, a discharge box 25 and a crushing hammer 14, a cylinder 2 is installed at the bottom of the crushing box 1, and a spring 3 is installed inside the cylinder 2 , the base 4 is installed at the bottom of the spring 3, the upper left side of the crushing box 1 is provided with a feed port 5, the middle part of the top of the crushing box 1 is equipped with a motor frame 6, and the inner side of the motor frame 6 is equipped with a second motor 32, the second motor 32 shaft The front end is equipped with a turntable 7, the edge of the turntable 7 is equipped with a rotating shaft 8, the outer side of the rotating shaft 8 is equipped with a connecting rod 9, the bottom end of the connecting rod 9 is equipped with a first fixed frame 10, and the bottom end of the first fixed frame 10 is equipped with a long rod 11 , the outer side of the long rod 11 is pro...

Embodiment 3

[0028]In the embodiment of the present invention, a pulverizer for reinforced concrete includes a crushing box 1, a discharge box 25 and a crushing hammer 14. A cylinder 2 is installed at the bottom of the crushing box 1, and a spring 3 is installed inside the cylinder 2. The base 4 is installed on the bottom of the spring 3, the upper left side of the crushing box 1 is provided with a feed port 5, the middle part of the top of the crushing box 1 is installed with a motor frame 6, the inner side of the motor frame 6 is installed with a second motor 32, and the front end of the second motor 32 shaft Rotating disk 7 is installed, rotating shaft 8 is installed on the edge of rotating disk 7, and connecting rod 9 is installed on the outer side of rotating shaft 8, and the bottom end of connecting rod 9 is installed with the first fixed frame 10, and the bottom end of the first fixed frame 10 is equipped with long rod 11, The outer side of the long rod 11 is provided with a limit tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com