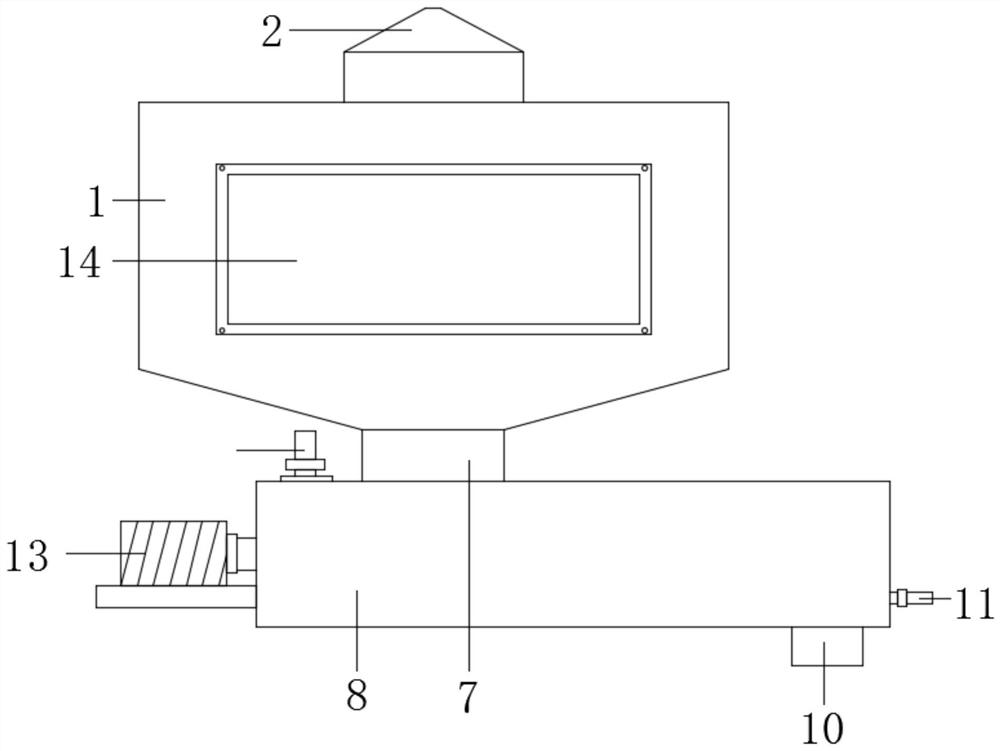

Environment-friendly wet paper shredder

A technology of paper shredding and wet method, which is applied in transportation and packaging, chemical instruments and methods, and dissolution, etc. It can solve problems such as poor crushing effect, unsatisfactory waste paper recycling effect, poor wetting effect and efficiency, etc. , achieve good wear resistance, reduce maintenance difficulty, and achieve good wetting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

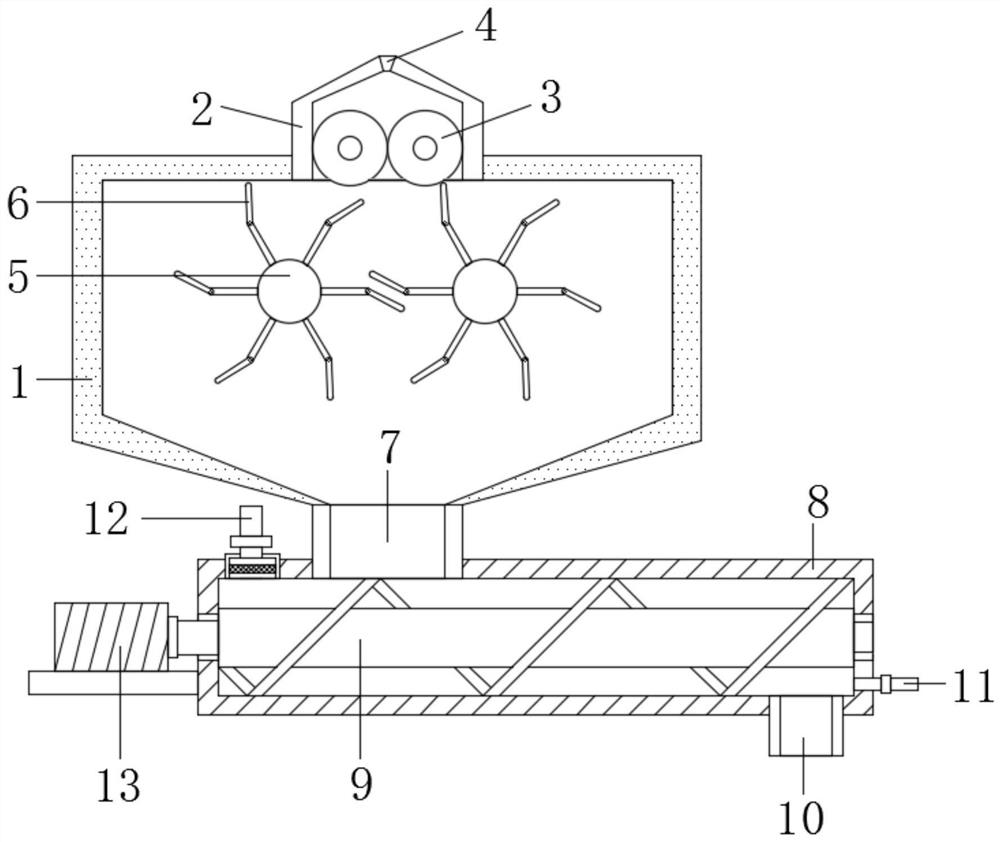

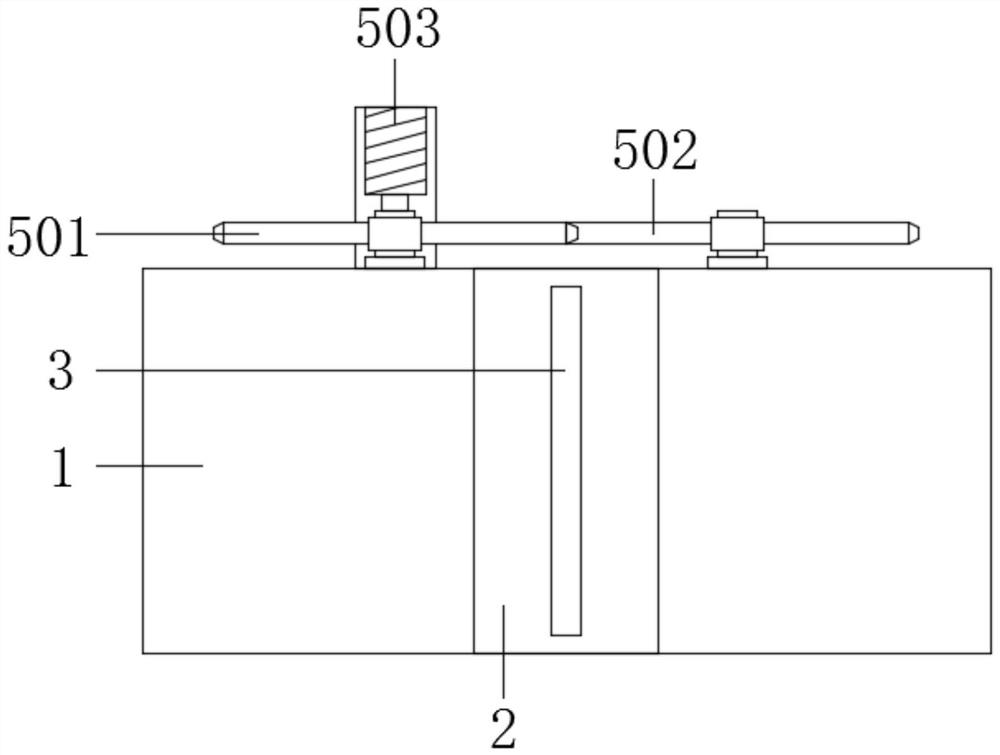

[0041] When the guide roller 3 was a common roller (referring to the accompanying drawings Figure 4 ), when in use, the waste paper is conveyed into the feed chamber 2 through the feed port 4, and the left guide drive shaft 301 is driven to rotate by the guide drive motor 304, while the guide drive gear 302 and the guide driven gear 303 mesh connected so that the two groups of guide rollers 3 are moving inwards, and the waste paper is squeezed and guided through the guide rollers 3, so that the waste paper can be kept in a vertical direction with the crushing teeth 6, which can facilitate the crushing teeth to carry out Crushing work, and the rotation direction of the two groups of crushing teeth is opposite, which can make the crushing effect better. The crushing drive motor 503 drives a group of crushing rollers 5 to rotate, and the crushing driving gear 501 on it drives the crushing driven gear to rotate , so that the two sets of crushing rollers 5 move in opposite directi...

Embodiment 2

[0043] When material guide roller 3 has friction protrusion 305 (referring to description accompanying drawing Figure 5 ), when in use, the waste paper is conveyed into the feed chamber 2 through the feed port 4, and the left guide drive shaft 301 is driven to rotate by the guide drive motor 304, while the guide drive gear 302 and the guide driven gear 303 mesh connected so that the two sets of guide rollers 3 are moving inwardly, and the waste paper is squeezed and guided through the guide rollers 3, and at the same time, the friction protrusions 305 arranged in a staggered manner can rub and fluff the paper, which is convenient Subsequent crushing allows the waste paper to be kept vertically perpendicular to the crushing teeth 6, which facilitates the crushing work of the crushing teeth, and the rotation direction of the two groups of crushing teeth is opposite, which can make the crushing effect better. The crushing drive motor 503 drives a The group of crushing rollers 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com