Chili product production equipment

A technology for production equipment and products, applied in the field of pepper product production equipment, can solve the problems of inability to filter peppers, inability to grind peppers, and chili powder easily choking on staff, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

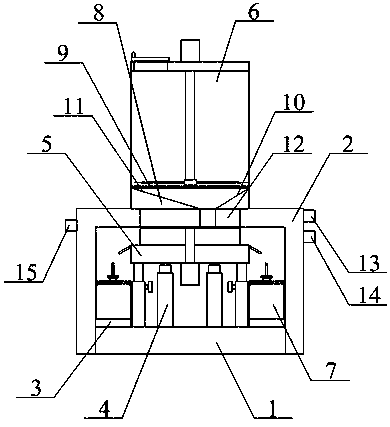

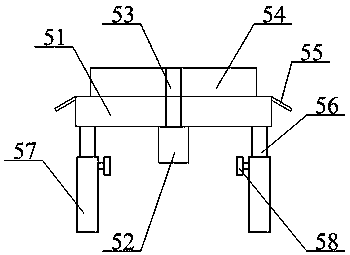

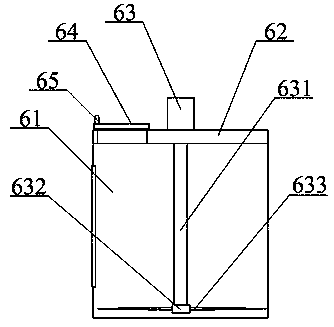

[0039] as attached figure 1 To attach Figure 4 shown

[0040]The invention provides a pepper product production equipment, comprising a base 1, a U-shaped fixed seat 2, a socket 3, a cylinder 4, a grinding adjustment grinding wheel structure 5, an anti-scattering crushing barrel structure 6, a windproof collection sampling box structure 7, and a discharge Bucket 8, material leakage plate 9, blanking plate 10, inclined plate 11, fixed grinding wheel 12, crushing switch 13, grinding wheel switch 14 and adjustment switch 15, the base 1 is bolted to the lower part of the inner wall of the U-shaped fixing seat 2 The sockets 3 are respectively welded on the left and right sides of the upper end of the base 1; the cylinder 4 is bolted to the left and right sides of the upper end of the base 1; the grinding adjustment grinding wheel structure 5 is installed on the upper end of the base 1; The anti-scattering crushing bucket structure 6 is installed on the upper end of the dump buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com