Waste recovery device for automotive interior trim production

A technology for recycling automobile interior parts and scraps, which is applied in the field of scrap recycling devices for the production of automobile interior parts, can solve the problems that the volume of plastic workpieces cannot be effectively reduced, the workpieces cannot be broken and relieved, etc., and can optimize the crushing effect and reduce the volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

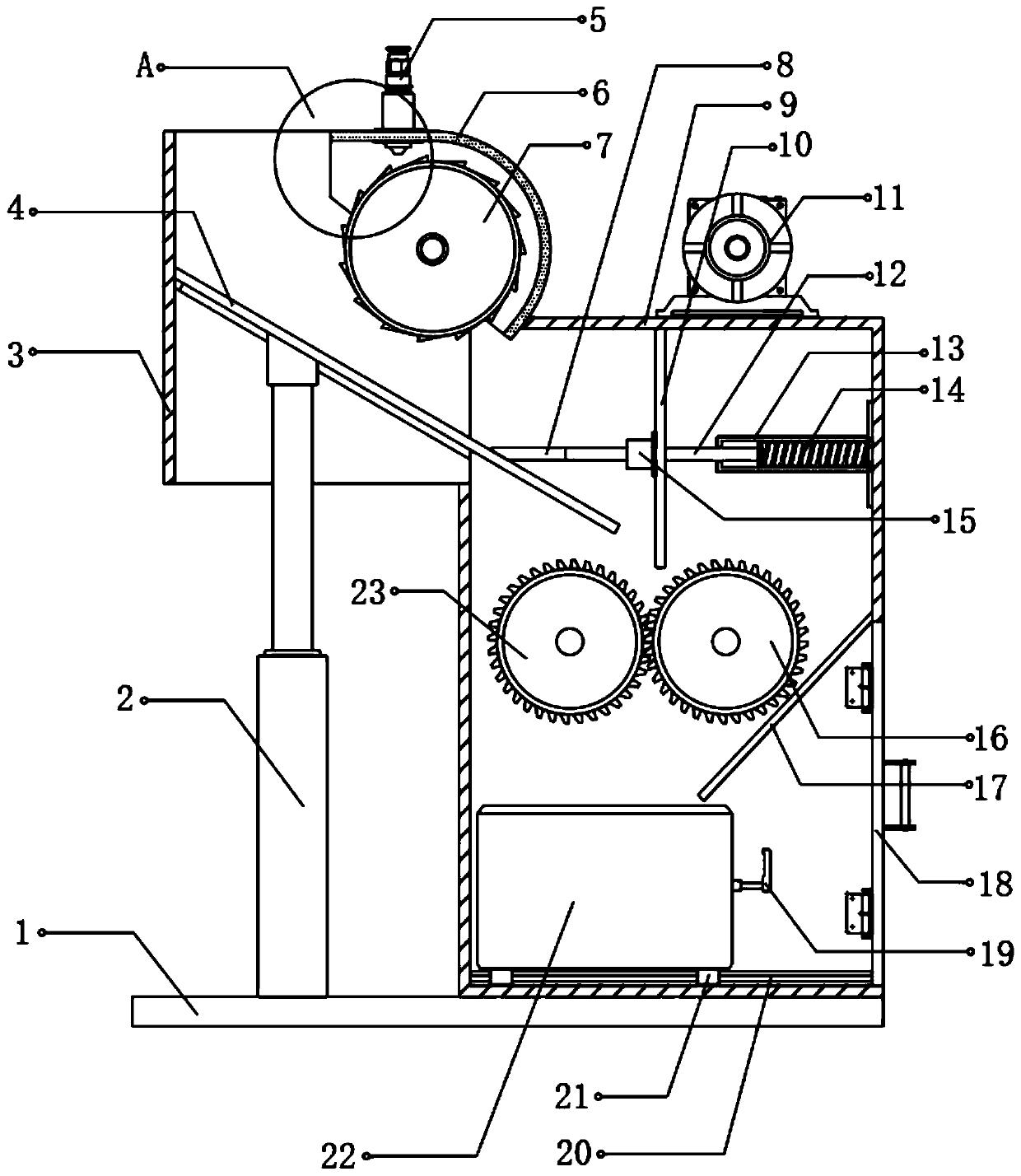

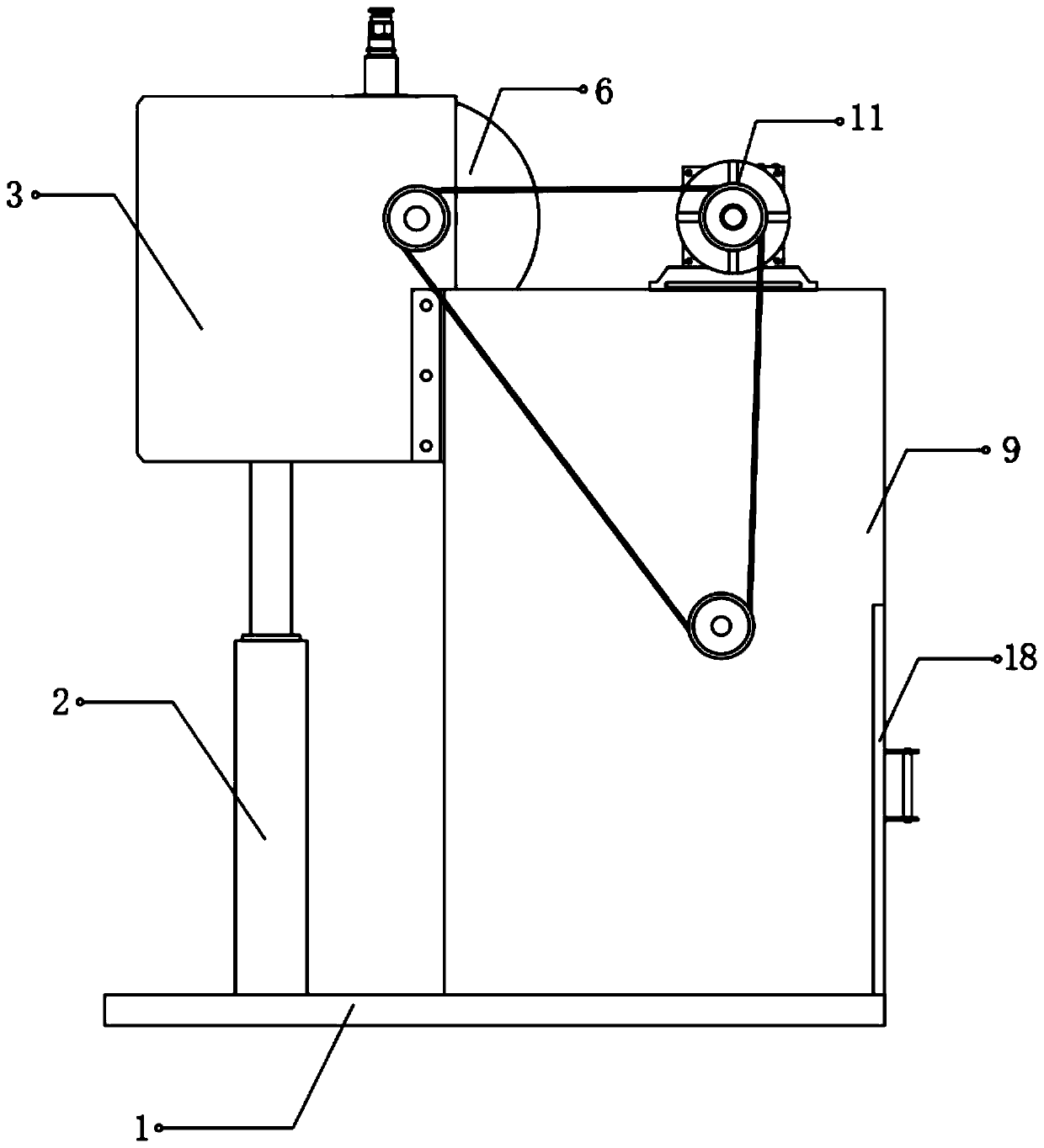

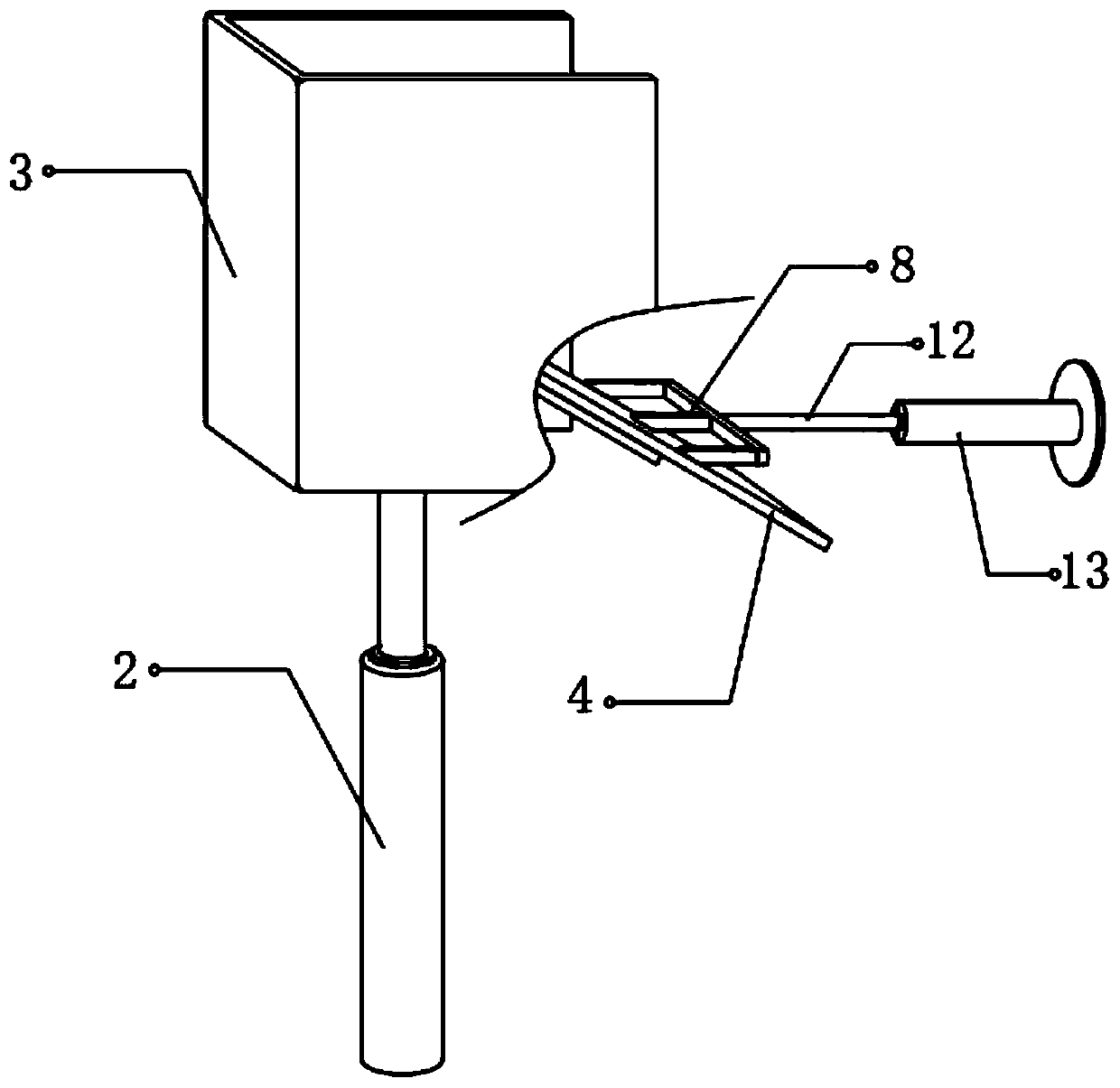

[0032] refer to Figure 1-4 , a waste recycling device for the production of automotive interior parts, comprising a base 1, one side of the top of the base 1 is fixedly connected with a box body 9, and the top of one side of the box body 9 is connected with an upper material cylinder 3 by bolts, and the upper material cylinder The inner wall of the middle part of 3 is fixedly connected with a blanking plate 4, and the bottom of the blanking plate 4 extends to the inside of the box body 9, and one side of the inner wall of the top of the upper barrel 3 is fixedly connected with a shield 6, and the inside of the shield 6 passes through The bearing is rotatably connected with a crushing roller 7, and the outer wall of the crushing roller 7 is welded with evenly distributed scrap teeth 25, and the top of the shield 6 is fixedly connected with a gas pipe joint 5, and the bottom end of the gas pipe joint 5 is fixedly connected with a nozzle 24, and the box The inner wall of body 9 ...

Embodiment 2

[0042] refer to Figure 5 , a waste recycling device for the production of automotive interior parts. Compared with Embodiment 1, the bottom of the inner wall on one side of the box body 9 is fixedly connected with an electromagnet 28, and the middle part of the material box 22 is close to the side of the electromagnet 28. Open arc groove, the inwall of arc groove middle part is welded with positioning block 27, and positioning block 27 adopts steel material, and the height of positioning block 27 is identical with the height of electromagnet 28, and the length of positioning block 27 and electromagnet 28 The sum is greater than the distance between the inner wall of the middle part of the arc groove and the inner wall of the box body 9, and the inner wall on one side of the box body 9 is bonded with two buffer pads 26, and the two buffer pads 26 are symmetrically distributed on both sides of the electromagnet 28 , the thickness of the buffer pad 26 is greater than the length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com