Expanding rust-preventing spot welding structural sealant for car, and preparation method thereof

An expansion type sealant technology, applied in the chemical industry, can solve the problems of difficulty in controlling the uniformity of pores and foaming, reducing the corrosion resistance of foamed antirust sealants, polluting the environment and the health of operators, etc., to achieve good elasticity, Excellent rust resistance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

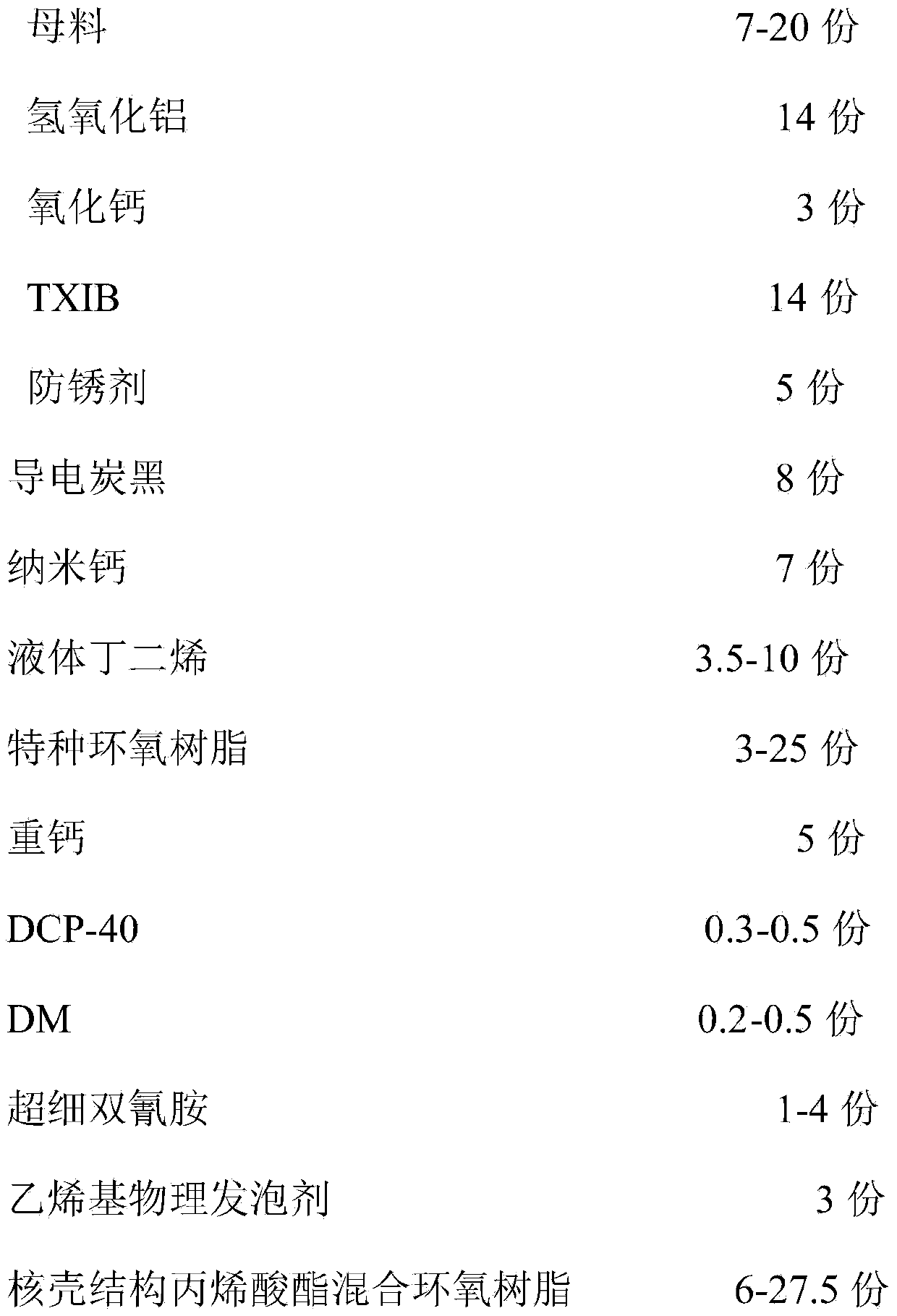

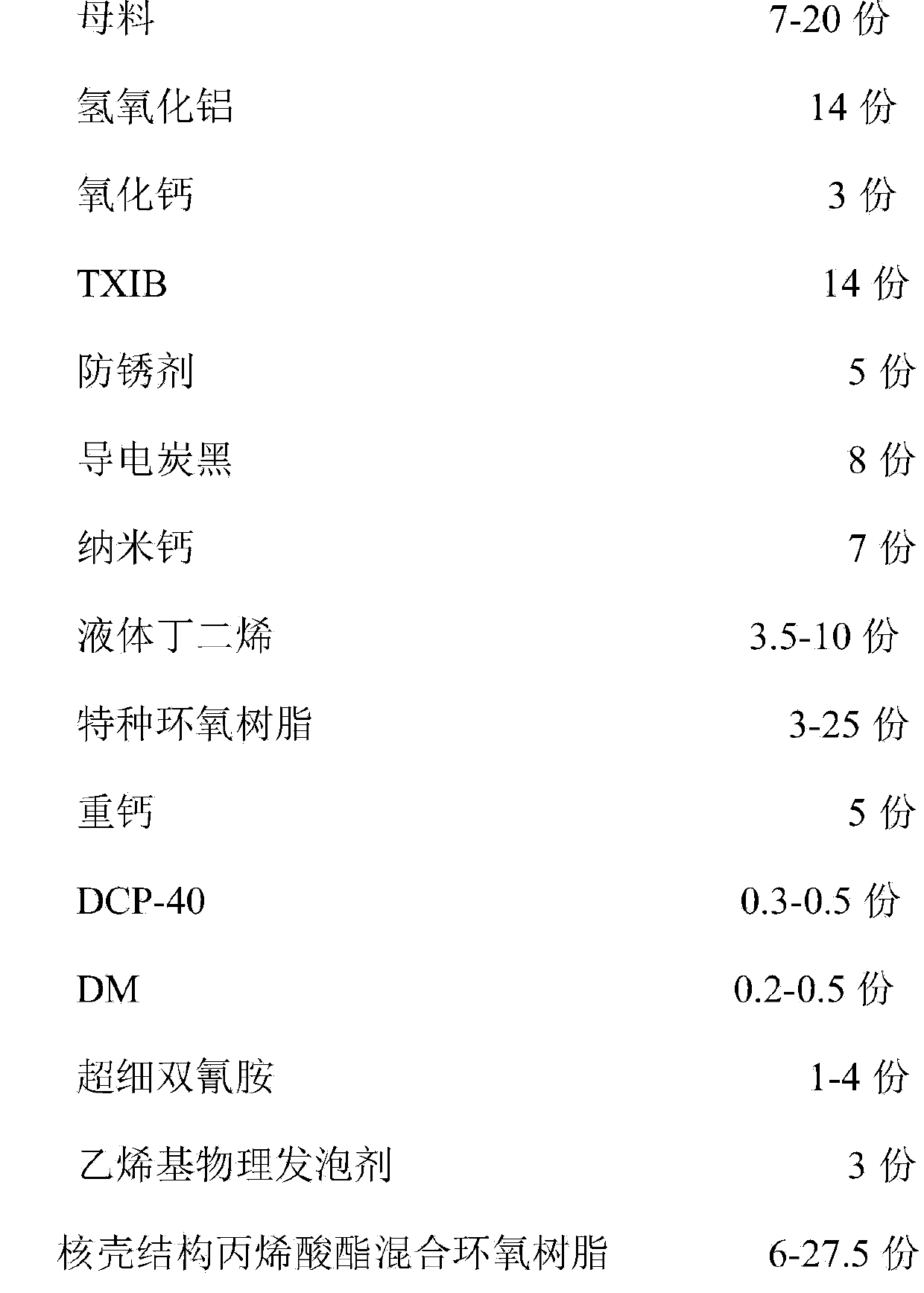

Examples

preparation example Construction

[0029] The preparation method of masterbatch one is:

[0030] Put 20 parts of low-molecular BR rubber and 30 parts of SBR rubber into the internal mixer for 20 minutes, then add 20 parts of heavy calcium into the internal mixer and mix for 30 minutes, then add 30 parts of TXIB, and add in 3 times, 10 parts each time, every addition is 10 minutes apart, and finally mixed in the internal mixer for 30 minutes and discharged for later use.

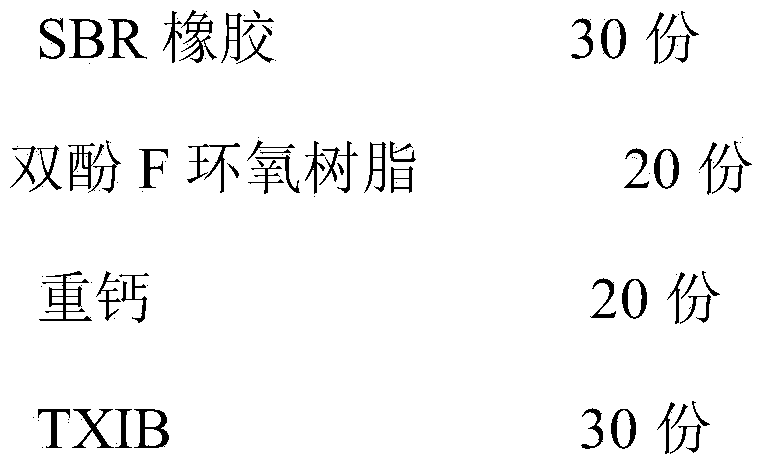

[0031] Masterbatch two parts by weight raw material composition is:

[0032]

[0033] The preparation method of masterbatch two is:

[0034] Put 30 parts of SBR rubber and 20 parts of bisphenol F epoxy resin into the internal mixer for 20 minutes, and then

[0035] Add 20 parts of heavy calcium to the internal mixer and knead for 30 minutes, then add 30 parts of TXIB, add in 3 times

[0036] Add, 10 parts each time, every addition is 10 minutes apart, and finally after 30 minutes of internal mixing in the internal mixer

[0037] The mat...

Embodiment 1

[0040] Intumescent automobile antirust spot welding structure sealant, its preparation method is:

[0041] Knead 20 parts of the prepared masterbatch, 8 parts of aluminum hydroxide, 3 parts of calcium oxide, and 3 parts of TXIB on the kneader for 30 minutes, then add 6 parts of aluminum hydroxide, 5 parts of antirust agent, and 8 parts of conductive carbon black , 5 parts of TXIB kneaded in a kneader for 15 minutes to make the material group, and then added 7 parts of nano-calcium, 10 parts of liquid butadiene, 3 parts of bisphenol F epoxy resin, and 3 parts of TXIB and kneaded in a kneader for 25 minutes. Then add 5 parts of heavy calcium, 0.5 parts of DCP-400, 0.5 parts of DM, 1 part of ultra-fine dicyandiamide, 3 parts of vinyl physical foaming agent and knead in a kneader for 20 minutes, add core-shell structure acrylate mixed epoxy resin Knead 6 parts in a kneader for 10 minutes, then add 1.5 parts of TXIB to adjust the viscosity, and finally reserve 1.5 parts of TXIB to ...

Embodiment 2

[0043] Intumescent automobile antirust spot welding structure sealant, its preparation method is:

[0044] Knead 20 parts of the prepared masterbatch, 8 parts of aluminum hydroxide, 3 parts of calcium oxide, and 3 parts of TXIB on the kneader for 30 minutes, then add 6 parts of aluminum hydroxide, 5 parts of antirust agent, and 8 parts of conductive carbon black , 5 parts of TXIB kneaded in a kneader for 15 minutes to make the material group, and then added 7 parts of nano-calcium, 10 parts of liquid butadiene, 3 parts of bisphenol F epoxy resin, and 3 parts of TXIB and kneaded in a kneader for 25 minutes. Then add 5 parts of heavy calcium, 0.5 parts of DCP-400, 0.5 parts of DM, 1 part of ultra-fine dicyandiamide, 3 parts of vinyl physical foaming agent and knead in a kneader for 20 minutes, add core-shell structure acrylate mixed epoxy resin Knead 6 parts in a kneader for 10 minutes, then add 1.5 parts of TXIB to adjust the viscosity, and finally reserve 1.5 parts of TXIB to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com