Paint production dispersion machine

A disperser and paint technology, applied in the direction of mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve the problem of volatilization of paint raw materials into the air, reduce air pollution, reduce volatilization, and improve gas collection volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

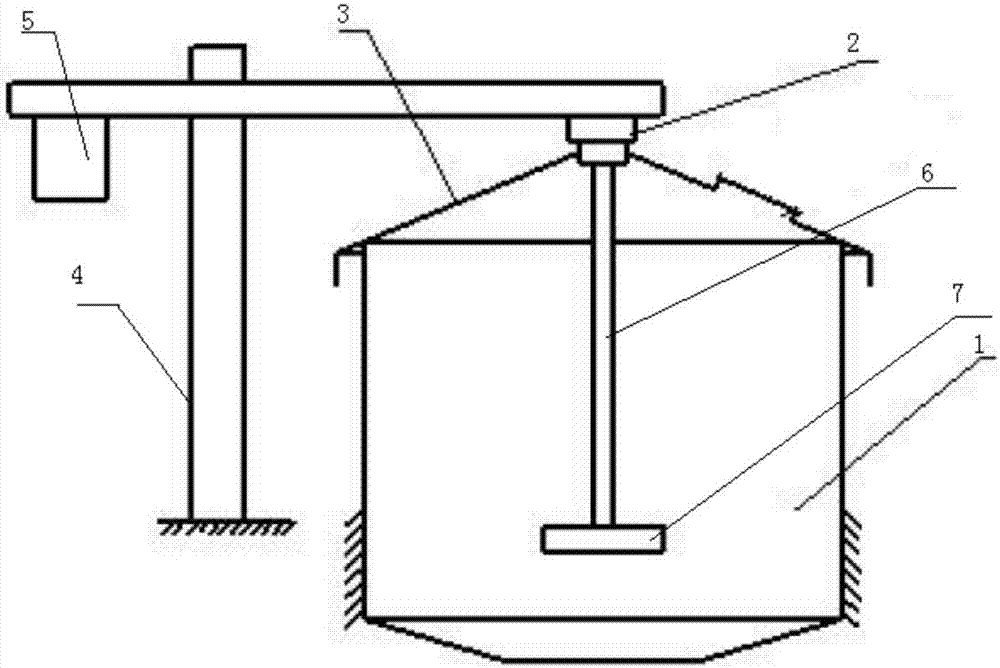

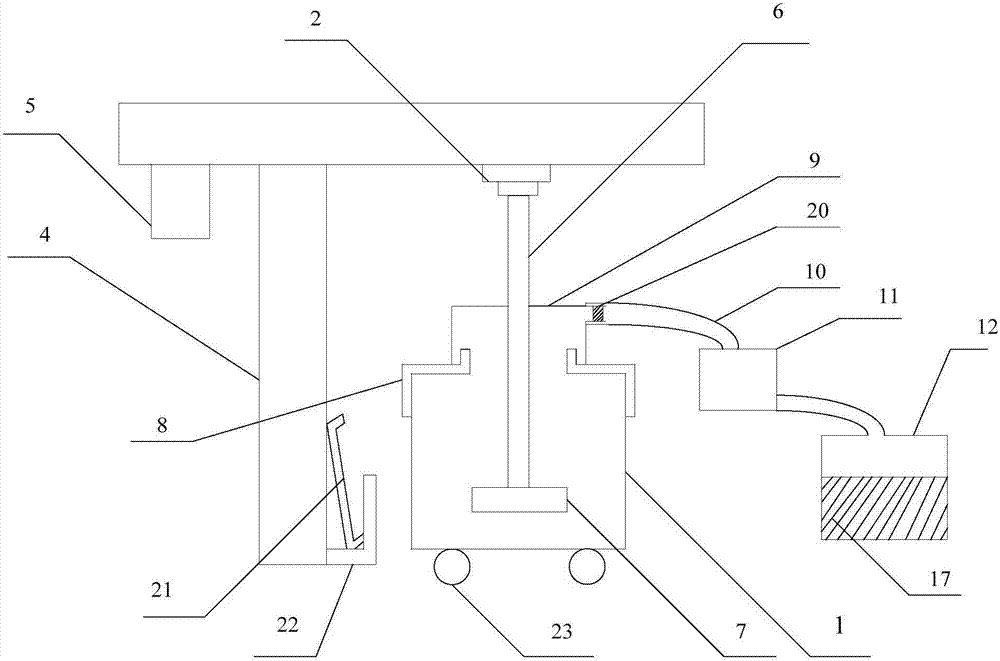

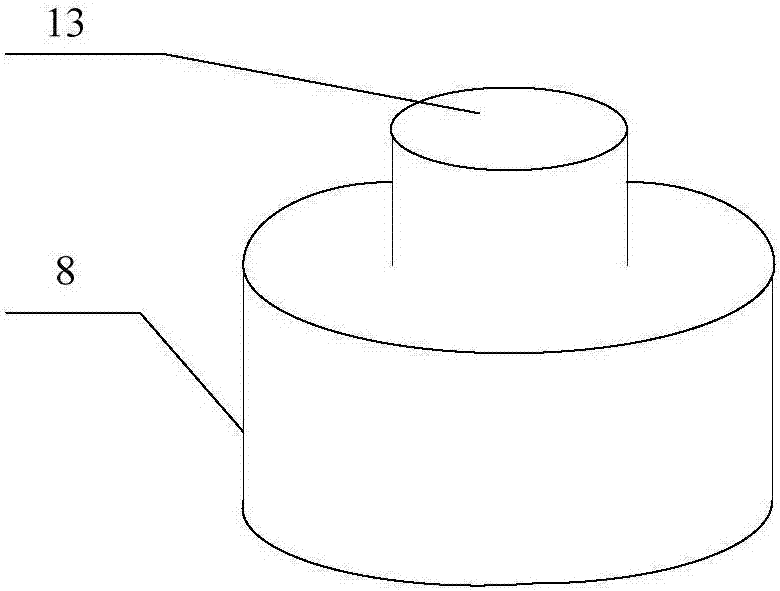

[0028] see figure 2 , a schematic structural diagram of a paint production disperser provided in the embodiment of the present application, such as figure 2 As shown, the paint production dispersion machine provided by the embodiment of the present application includes a dispersion tank 1, a paddle rod seat 2, a fixed bracket 4, a motor 5, a paddle rod 6, a dispersion disc 7, an open tank cover 8, and a multi-port connection Part 9, exhaust pipe 10, fan 11, gas collecting device 12, filter plug 20, top cover 21, top cover bracket 22 and universal wheel 23.

[0029] Specifically, the fixed bracket 4 is provided with a motor 5 , a paddle rod 6 seat 2 and a top cover bracket 22 . Wherein, the paddle rod 6 seat 2 is provided with a paddle rod 6 , and the end of the paddle rod 6 is provided with a dispersion disc 7 . The paddle rod 6 can go deep into the dispersion tank 1 along with the rotation of the motor 5, and disperse the paint raw materials in the dispersion tank 1 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com