High-efficiency intelligent exhaust gas treatment system

A waste gas treatment and intelligent technology, applied in the direction of steam condensation, cleaning method using gas flow, removing smoke and dust, etc., can solve problems such as hidden dangers to personal health and safety, and achieve the effects of reducing health threats, convenient disassembly and assembly, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

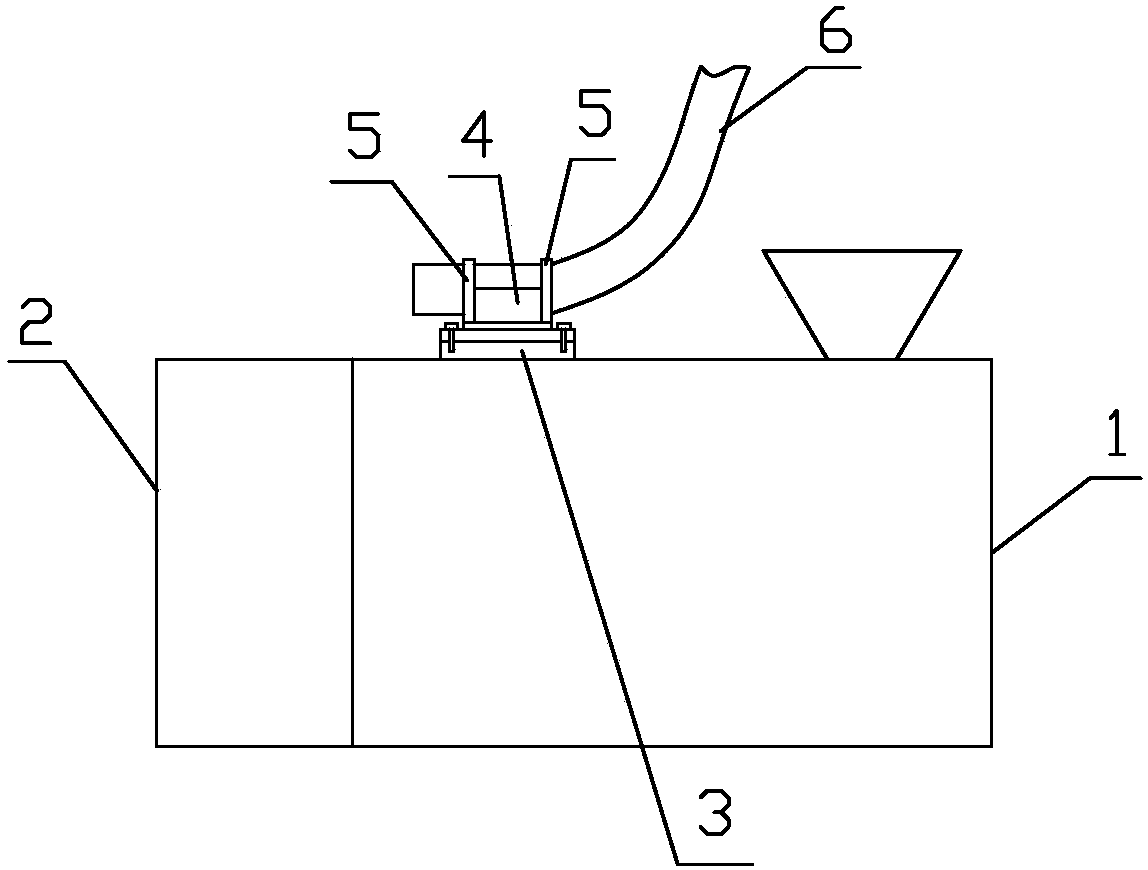

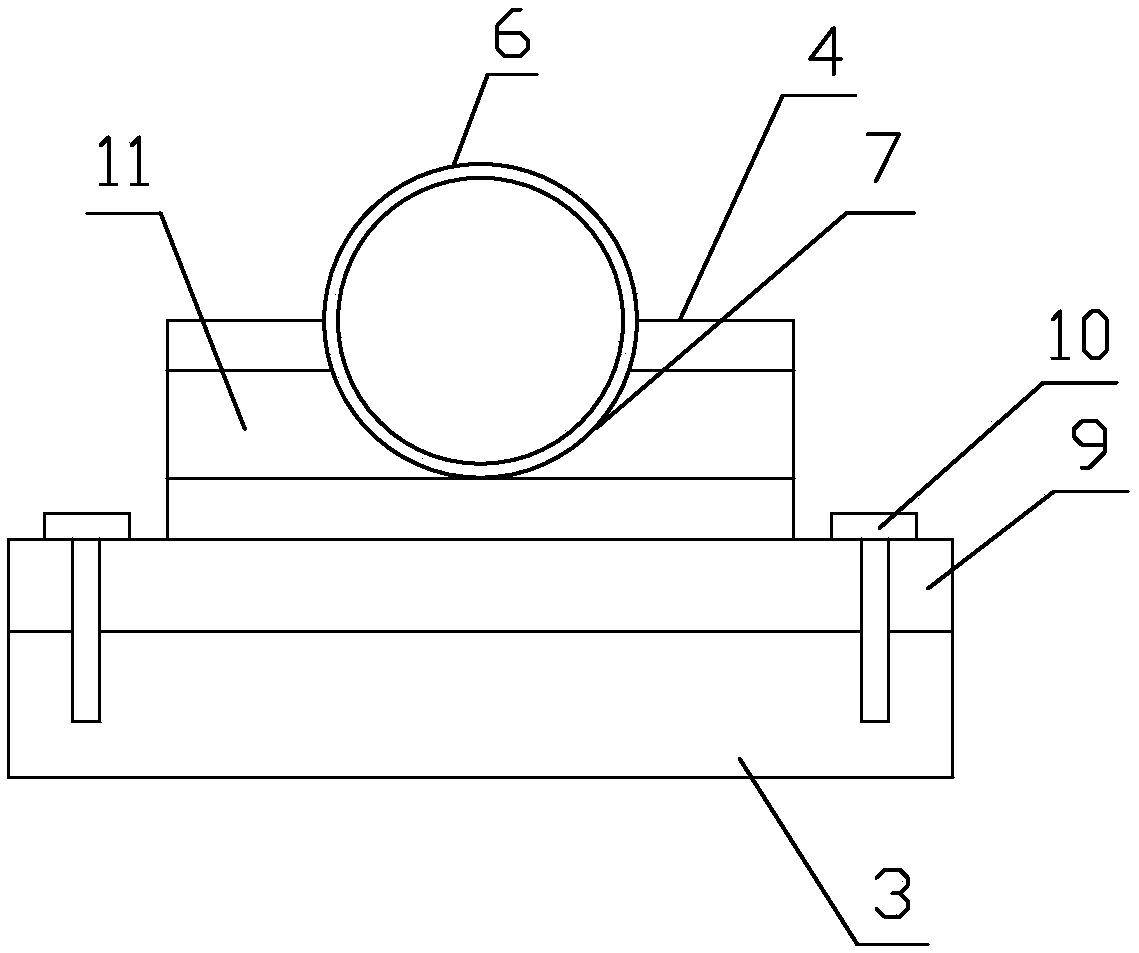

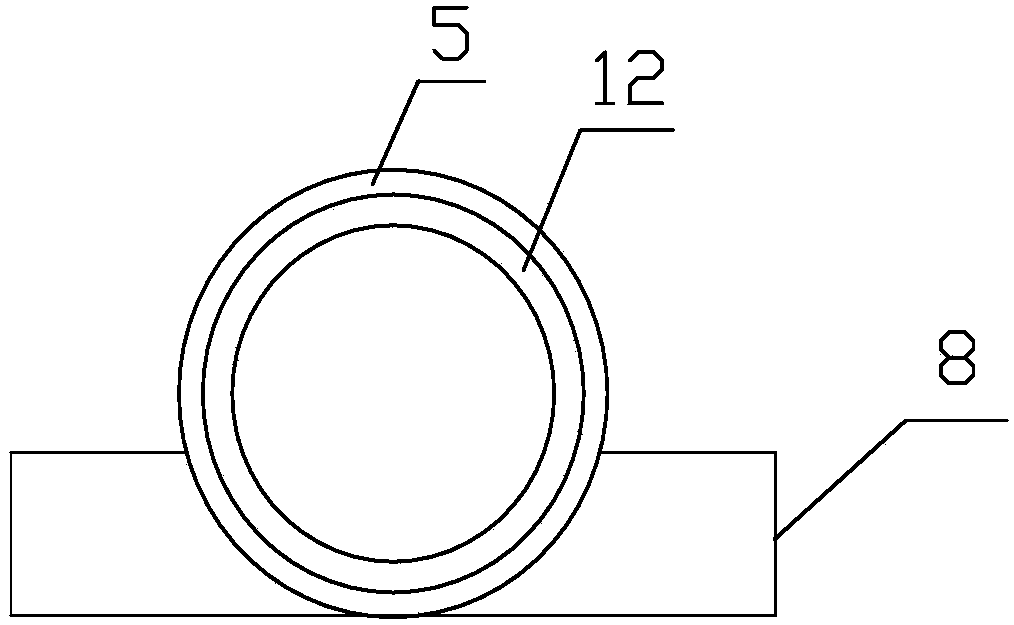

[0033] Such as Figure 1-5 As shown, an efficient and intelligent exhaust gas treatment system includes an injection molding machine body 1. A mounting base 3 is provided on the casing of the injection molding machine body 1 and close to the mold 2, and also includes a mounting block 4, a snap ring 5 and a suction The bottom surface of the mounting block 4 is detachably set on the mounting base 3, and the top surface of the mounting block 4 is provided with a semicircular groove 7 for receiving the suction collection tube 6; Two snap rings 5 are provided on the transitional fitting sleeve of the input end pipe section of the suction collection tube 6, when the suction collection tube 6 is inserted into the groove 7, the mounting block 4 is located between the two snap rings 5, The outer diameter of the snap ring 5 is larger than the inner diameter of the groove 7, and the side wall of the snap ring 5 is provided with a limiting plate 8, and the limiting plate 8 is detachably ...

Embodiment 2

[0035] Further improved on the basis of embodiment 1, the suction collection pipe 6 is composed of a number of short pipes 17 which are connected end-to-end through flanges 18, and is from the input end of the injection molding machine body 1 to the output end of the connecting pipeline 13 The tube inner diameter of each short tube 17 decreases sequentially.

Embodiment 3

[0037] It is further improved on the basis of Embodiment 2, and further includes a buffer chamber 19, the side wall of the buffer chamber 19 at the top is provided with a number of air inlets distributed along the circumferential direction, and a number of suction collectors installed on the body 1 of the injection molding machine The output end of the pipe 6 is installed at the air inlet through a flange 18, and a second suction pump 21 is provided on the suction collecting pipe 6, and the air inlet where the suction collecting pipe 6 is not installed is blinded Blue seal; the top side wall of the buffer chamber 19 is also provided with an exhaust port, and the exhaust port is located above the air inlet, and the exhaust port is in communication with the connecting pipe 13. The exhaust pipe 16 is provided with an adsorption packing layer, and the adsorption packing layer is filled with activated carbon or molecular sieve solid adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com