PPS (polyphenylene sulfide) composite material and preparation method thereof

A polyphenylene sulfide and composite material technology, applied in the field of polymer materials, can solve the problems of unfavorable environment and personnel health, low content of thermally conductive fillers, affecting the flame retardant performance of PPS, etc., so as to reduce workplace pollution and personnel health threats. , Improve processability and thermal conductivity, and facilitate the effect of thermal network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

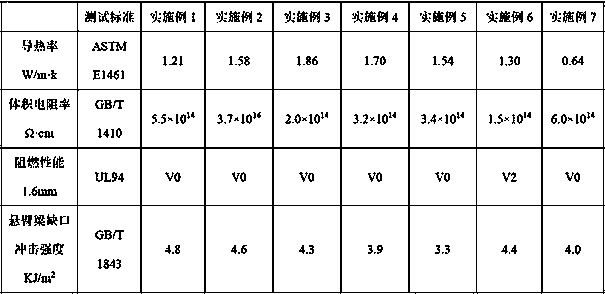

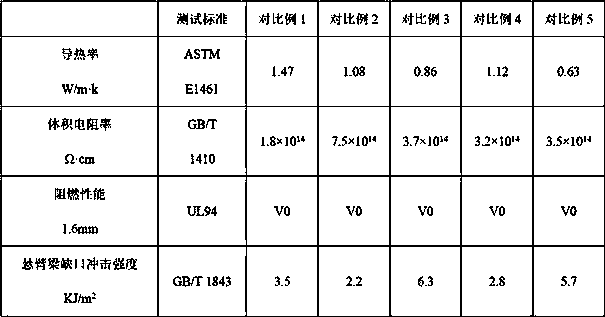

Examples

preparation example Construction

[0046] The preparation method of the thermally conductive masterbatch in the step S1 is as follows:

[0047] S11. Prepare raw materials. Provide PA12, magnesium oxide, antioxidant, dispersant and lubricant in the following weight percentages,

[0048] PA12 13.5~19%

[0049] Small particle size magnesium oxide (magnesia-S) 20~65%

[0050] Large particle size magnesium oxide (magnesia-L) 20~65%

[0051] Antioxidant 0.2~0.5%

[0052] Lubricant 0.5~1.0%;

[0053] S12. Mixing raw materials. Add the prepared PA12, large particle size magnesium oxide, antioxidant, dispersant and lubricant into the pressurized rotary mixer, control the temperature of the mixing room at 160~200°C, and the screw speed at 40~100r / min, the banburying time is 5~15min; after the raw materials form into agglomerates, then add the small particle size magnesium oxide into the banbury mixer, and then banbury for 5~15min;

[0054] S13. Preparation of thermally conductive masterbatch. The dough after ban...

Embodiment 1

[0058] (1) Preparation of thermally conductive masterbatch 1 with PA12 as the substrate, the raw material formula of its weight percentage (%):

[0059] PA12 (5g / 10min) 13.5

[0060] Magnesium oxide-S (5μm) 85

[0061] 1098 0.1

[0062] 168 0.2

[0063] H3336 0.2

[0064] PETS 1.0

[0065] Processing process: Add the prepared PA12, half the amount (50%) of magnesium oxide-S, antioxidant, dispersant and lubricant into the pressurized rotary internal mixer, and control the temperature of the internal mixing chamber to 160° C, banburying for 5 minutes at a screw speed of 40r / min; after the raw materials form agglomerates, add the remaining magnesium oxide-S into the internal mixer, and then banbury for 5min; send the above-mentioned agglomerates through the conveyor belt into the hopper of the single-screw extruder, cut into pieces by the hopper cutter, and then enter the barrel of the extruder through extrusion and gravity, and melt, knead and extrude through the single-scr...

Embodiment 2

[0072] (1) Preparation of thermally conductive masterbatch 2 with PA12 as the substrate, the raw material formula (%) of its weight percentage:

[0073] PA12 (9g / 10min) 13.5

[0074] Magnesium Oxide-L (40μm) 20

[0075] Magnesium oxide-S (5μm) 65

[0076] 1098 0.1

[0077] 168 0.2

[0078] H3336 0.2

[0079] PETS 1.0

[0080] Processing process: Add the prepared PA12, magnesium oxide-L, antioxidant, dispersant and lubricant into the pressurized rotary mixer, control the temperature of the mixing chamber to 160°C, and the screw speed to 40r / min Banbury for 5 minutes; after the raw materials form a ball, add magnesium oxide-S to the internal mixer, and then banbury for 5 minutes; send the above-mentioned ball after banburying to the hopper of the single-screw extruder through the conveyor belt, Cut into pieces through the hopper cutter, then enter the barrel of the extruder through extrusion and gravity, and melt, knead and extrude through a single-screw extruder (the spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com