A kind of production method of polyurethane foam powder solid waste particles

A technology of polyurethane foam and production method, applied in coating and other directions, can solve the problems of increased transportation and storage costs, low solid waste density, increased production costs, etc., so as to reduce transportation costs and storage costs, reduce dust generation, reduce The effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

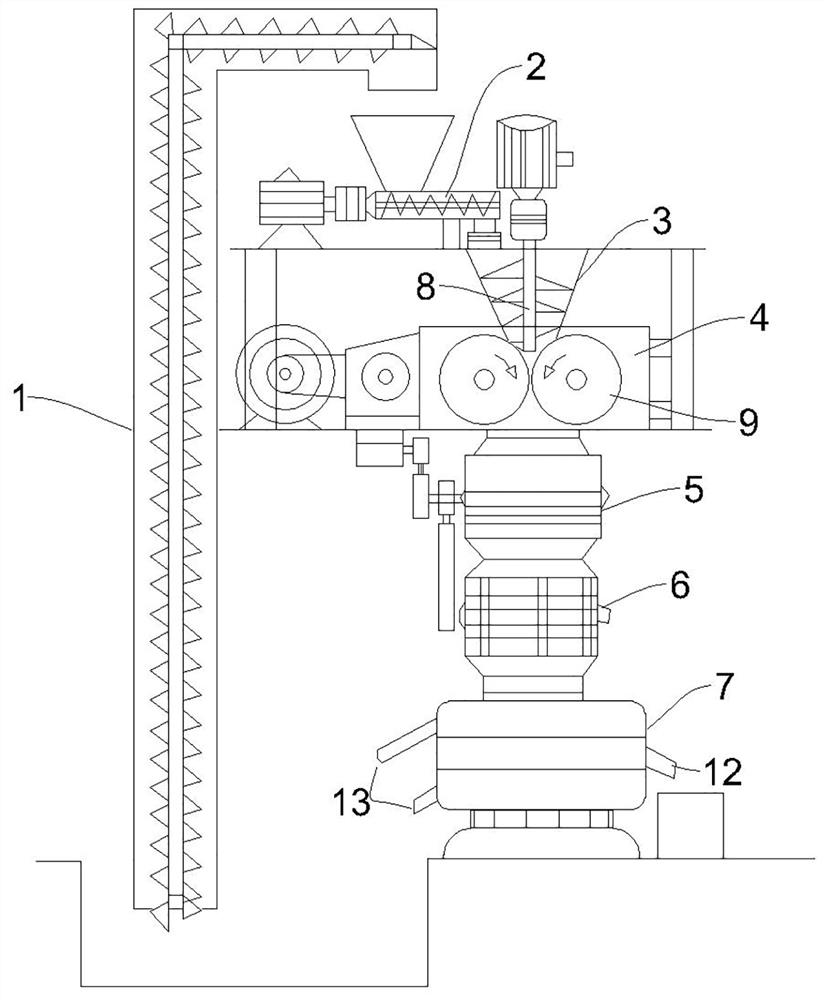

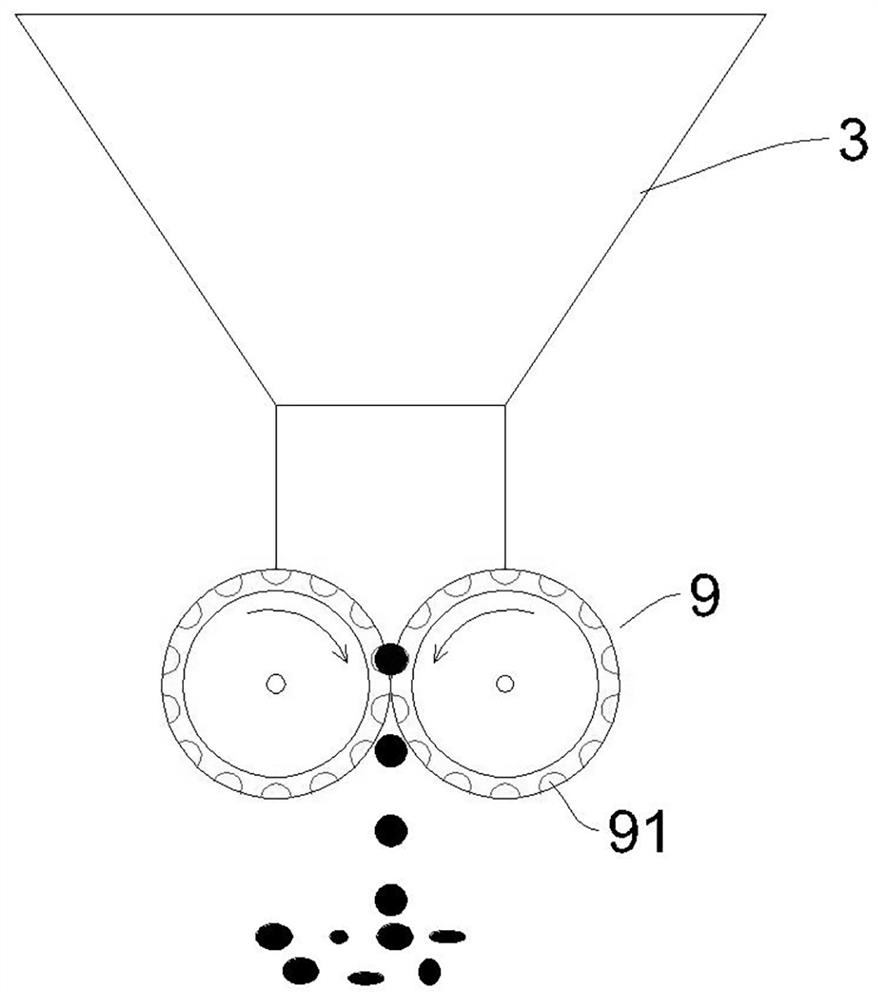

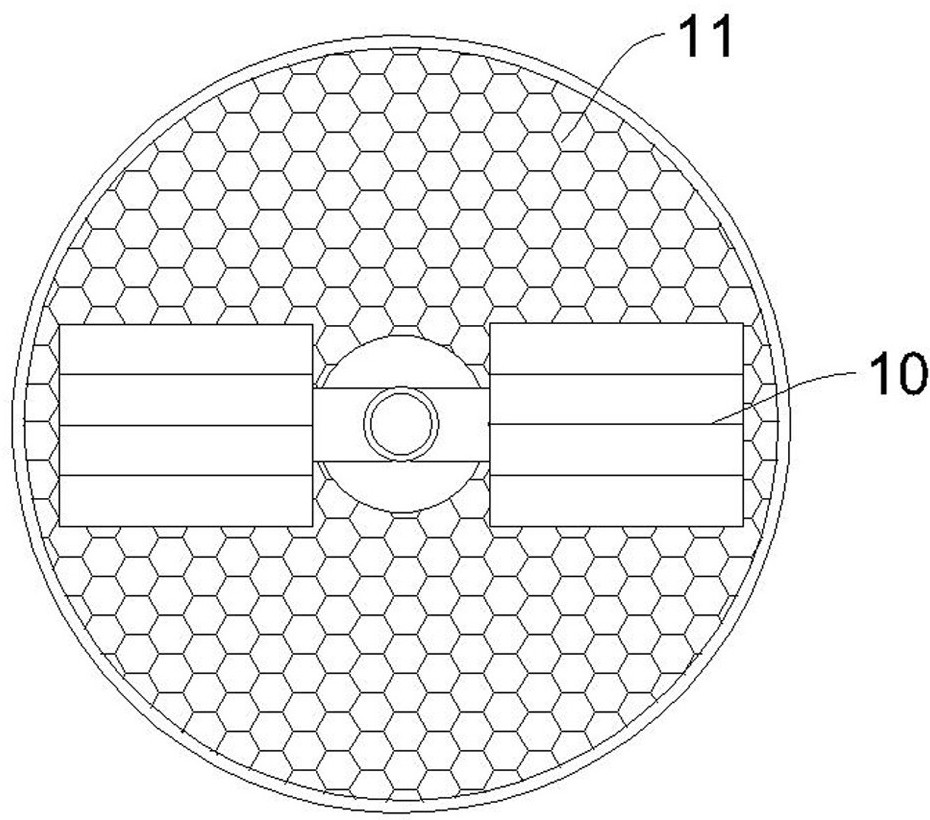

[0031] A kind of production method of polyurethane foam powder solid waste particle, the equipment that needs to use such as figure 1 As shown, it includes an elevator 1, a screw compressor 2, a pressurized hopper 3, a counter-roll granulator 4, a first roller granulator 5, a second roller granulator 6, and a sieving machine 7 arranged in sequence. ; The discharge end of the screw compressor 2 is provided with a briquetting block for adjusting the discharge density; the pressurized hopper 3 is provided with a spiral stirring paddle 8, which is used to stir and pressurize the initially agglomerated material to the pair of rollers Granulator 4, the paddle distribution of screw paddle 8 is dense at the top and sparse at the bottom; the roller granulator 4 includes the pair of rollers 9 with die holes 91 on the surface, and the two pairs of rollers 9 are bonded and extruded The material is molded into granules (such as figure 2 shown); the first roller granulator 5 and the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com