Feeding equipment for solid waste disposal equipment

A technology of processing equipment and feeding equipment, which is applied in the field of feeding equipment and solid material feeding equipment, can solve problems such as difficult feeding, uneven feeding, and increased energy consumption, so as to avoid damage, improve processing efficiency, and solve Difficult cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

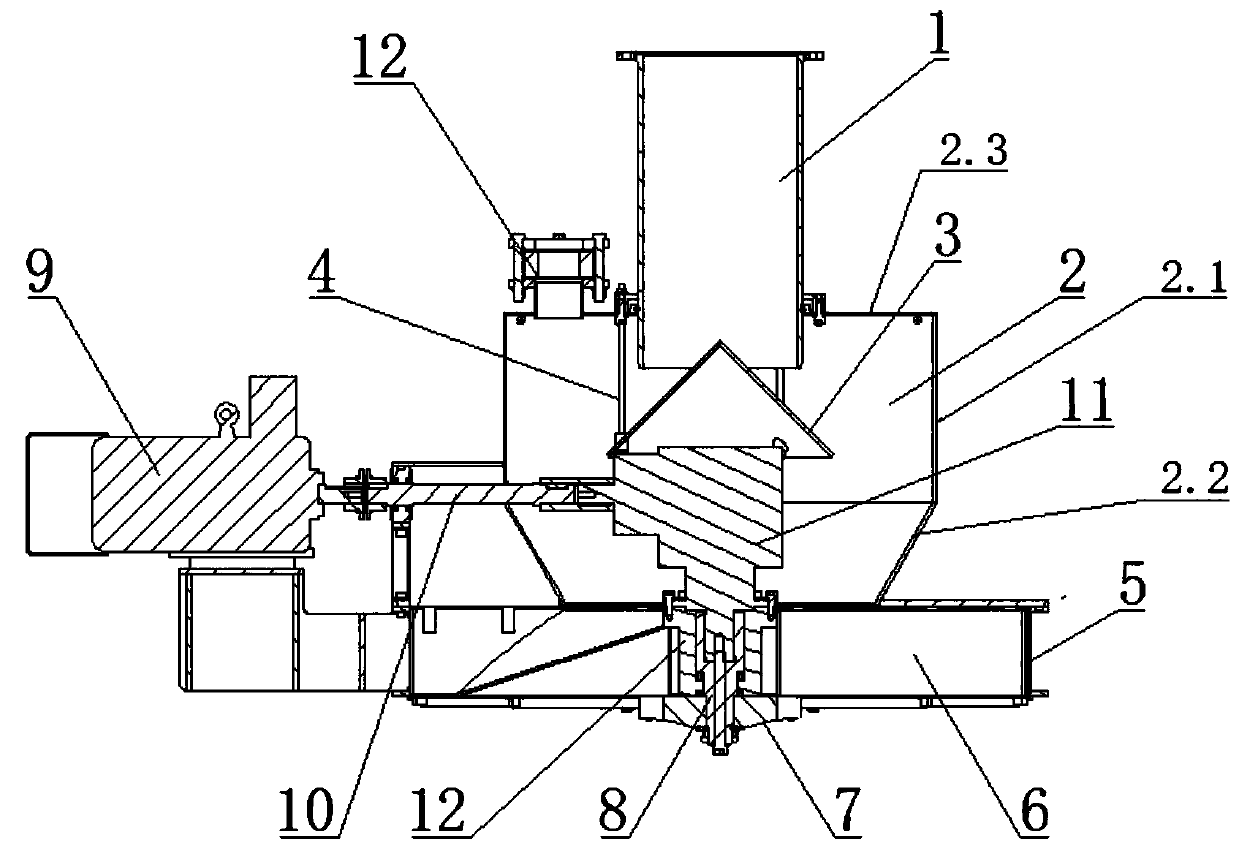

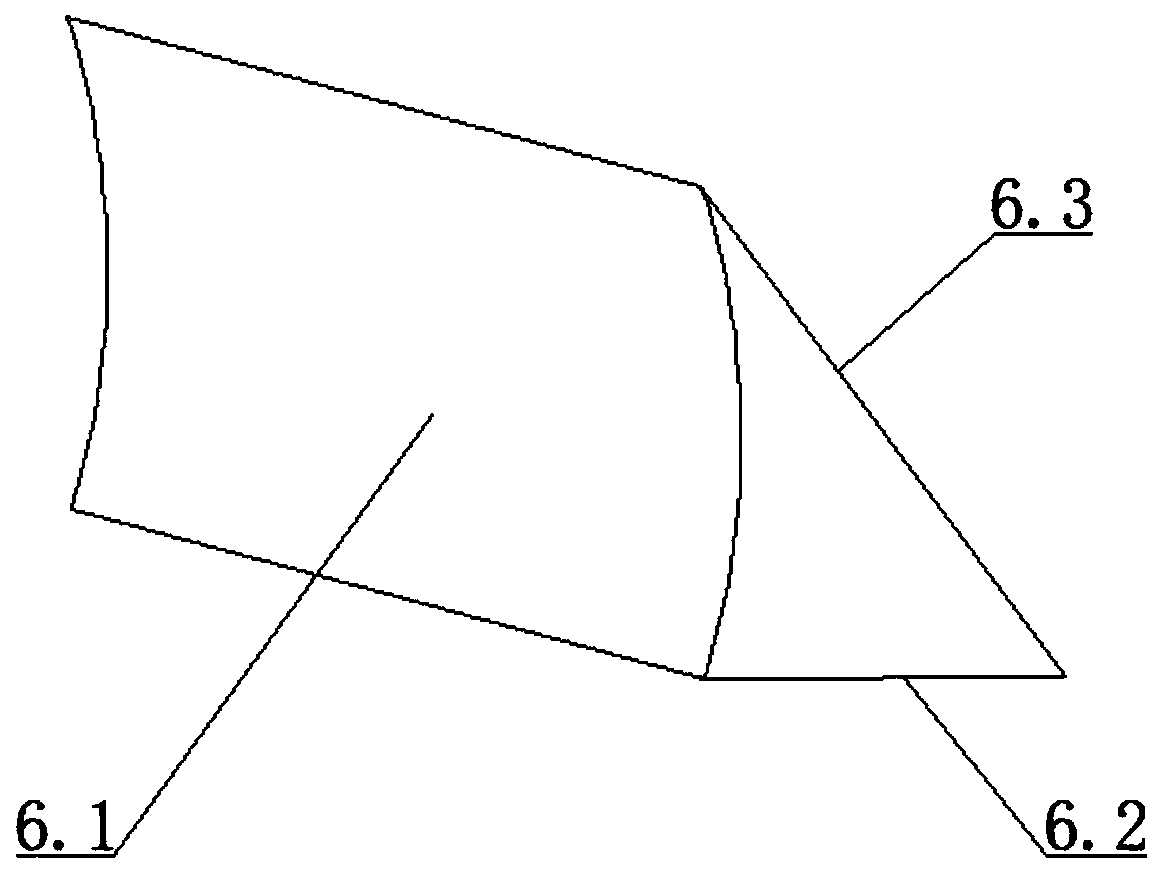

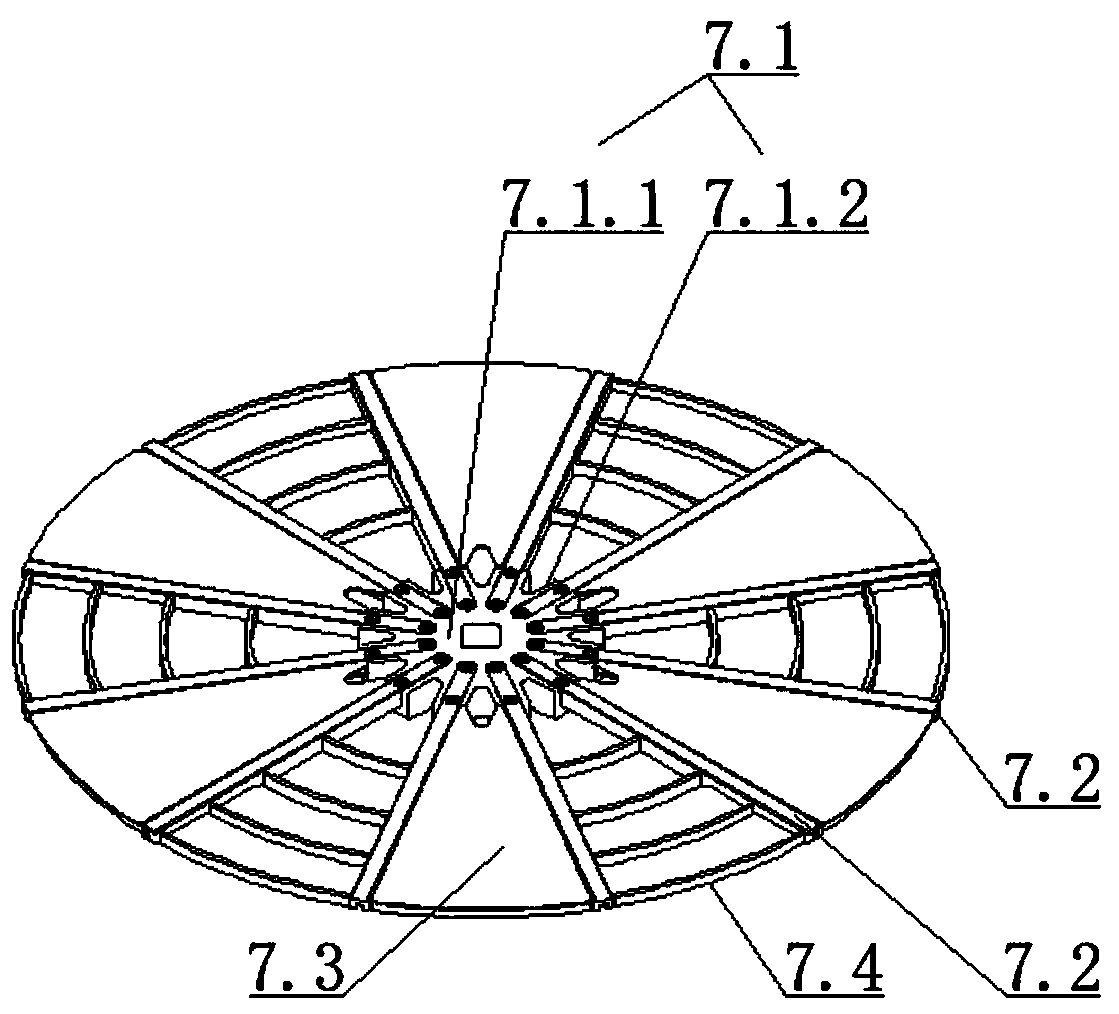

[0020] A feeding device for solid waste treatment equipment (see figure 1 ), including the lower silo 2, the lower silo 2 includes a ring-shaped mounting top plate 2.3, a cylindrical upper silo body 2.1 and a bell-mouthed diversion silo body 2.2, the mounting top plate 2.3 is equipped with a feed pipe 1, a cone The shape 3 is installed in the lower silo 2 through multiple suspension rods 4 and located below the feed pipe 1. The number of suspension rods is 3, 4 or 5, which can be set reasonably according to the weight of the cone; install the top plate 2.3 And the diversion silo body 2.2 are respectively installed on both sides of the upper silo body 2.1; the vertical axis reducer 11 is installed in the lower silo 2 and locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com