Special heat-salinity-resistant drag reducer for shale gas fracturing and manufacturing technology thereof

A production process and drag reducing agent technology, applied in the field of chemical preparations, can solve the problems of reduced effective working pressure of slick water, increased motion resistance of slick water, poor shear resistance, etc., and achieves low production cost, reduced damage and shear resistance good cut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

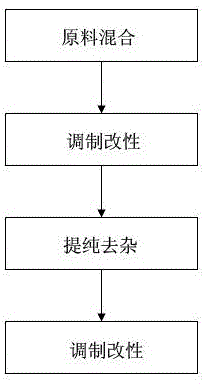

Image

Examples

Embodiment 1

[0023] A temperature-resistant, salt-resistant and drag-reducing agent for shale gas fracturing, made of the following raw materials in mass percentage: non-ionic monomer: 21%, salt-resistant monomer: 20%, emulsifier: 5%, initiator: 0.5%, sodium bisulfite: 1.2%, organic solvent: 11%, phase inversion agent: 2%, and the balance is deionized water.

[0024] In this embodiment, the nonionic monomer is N-methacrylamide.

[0025] In this embodiment, the emulsifier is Span 20 series.

[0026] In this embodiment, the initiator is a redox initiator.

[0027] In this embodiment, the redox agent is potassium carbonate / sodium bisulfite.

[0028] In this embodiment, the organic solvent is polymer oil.

[0029] In this embodiment, the phase inversion agent is nonylphenol polyoxyethylene ether.

[0030] A production process of a special temperature-resistant, salt-resistant and drag-reducing agent for shale gas fracturing, comprising the following steps:

[0031] The first step is to mi...

Embodiment 2

[0036] A temperature-resistant and salt-resistant drag reducer for shale gas fracturing, made of the following raw materials in mass percentage: non-ionic monomer: 25%, salt-resistant monomer: 17%, emulsifier: 7%, initiator: 0.5%, sodium bisulfite: 1%, organic solvent: 13%, phase inversion agent: 1.5%, and the balance is deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com