Industrial coating spraying device with purification function

A technology of spraying device and paint spraying gun, applied in the direction of spraying device, spraying device, etc., can solve the problems of operator's health threat, particle easily adhering to the surface of other objects, etc., and achieve the effect of reducing health threat and possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

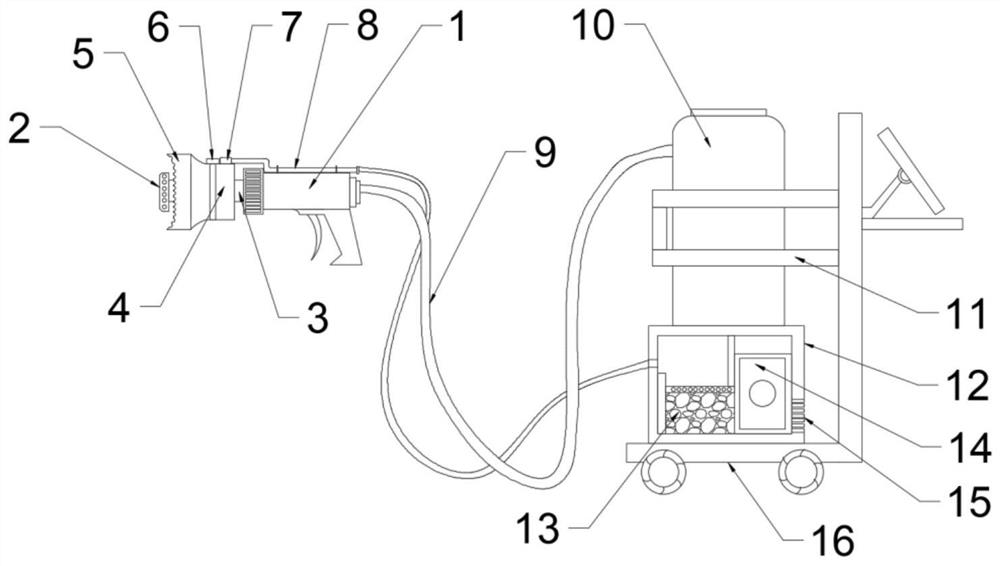

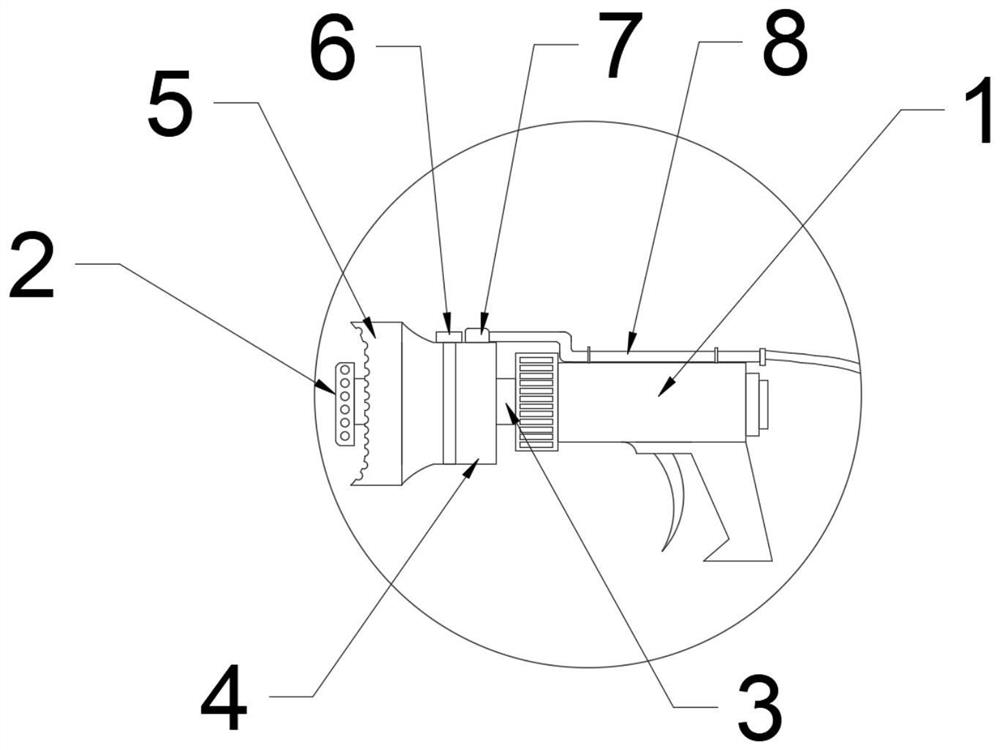

[0025] see Figure 1 to Figure 3 , an industrial paint spraying device with purification function, including paint spray gun 1, paint nozzle 2, spray pipe 3, annular suction plate 5, filter insert 6, suction pipe 8 and purification box 12, which are used for spraying The paint spray gun 1 of the paint is internally provided with a spray pipe 3, the left side of the spray pipe 3 is connected with a paint nozzle 2, an annular suction plate 5 is fixedly installed around the paint nozzle 2, and the right side of the annular suction plate 5 is provided with a filter insert block 6. The filter insert 6 is movably installed on the paint spray gun 1. The right side of the filter insert 6 is provided with a suction pipe 8. The suction pipe 8 is communicated with the purification box 12. The suction pipe 8 includes an activated carbon box 13 and a suction pipe 8. The air pump 14 and the activated carbon box 13 are arranged on the left side of the air suction pump 14 .

[0026] The left...

Embodiment 2

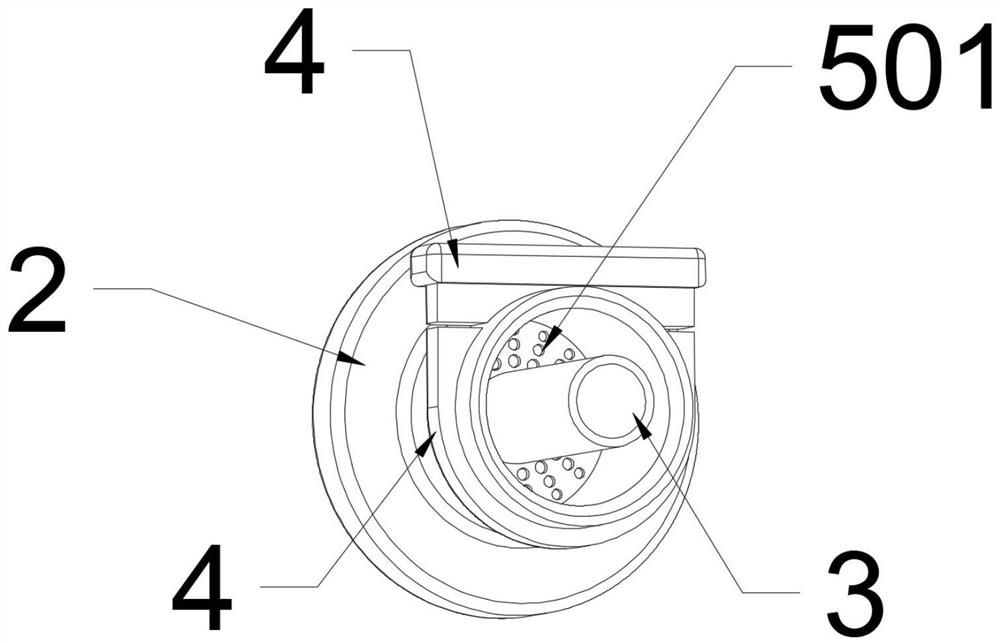

[0030] see Figure 4 , an industrial paint spraying device with a purification function, the main structure of which is the same as that of Embodiment 1, and an improvement is made to the suction chamber 4, and the filter insert 6 on the suction chamber 4 is replaced with a horizontal two-way insertion. The insert 601 has a channel 603 on the suction cavity 4, the transverse insert 601 is inserted into the suction cavity 4 through the channel 603, and an arc filter 602 is fixedly installed on the transverse insert 601.

[0031] The working principle of the present invention is: when the paint nozzle 2 is spraying paint, the paint particles sputtered from the paint nozzle 2 and the sprayed material are sucked into the suction chamber 4 from the suction hole 501 on the annular suction plate 5 At this time, the paint particles are adsorbed on the surface of the arc filter 602, and the remaining gas enters the purification box 12 through the paint pipe 9, and the gas purification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com