A kind of fracture cleaning method of nickel base superalloy

A nickel-based superalloy and fracture technology, which is used in the field of general inhibition of corrosion or fouling of metal materials, can solve problems such as long service time, complex manufacturing process, damage to fracture texture information, etc., to reduce stress corrosion and stress fatigue fractures Damage to texture, preservation of fracture morphology, no long-term toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

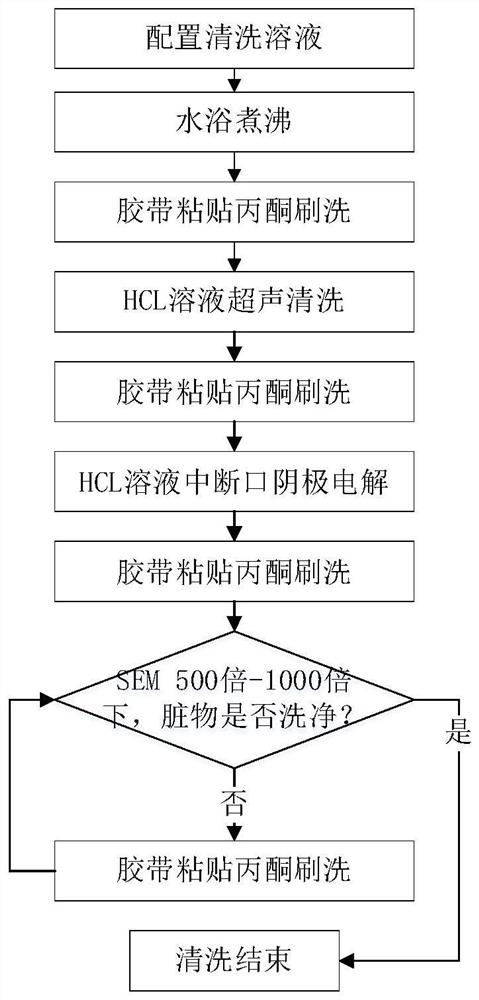

Method used

Image

Examples

Embodiment 1

[0034] Specific steps for cleaning the fracture of GH6783 nickel-based superalloy that has been in service for 23,000 hours:

[0035] Step 1) Prepare cleaning solution, add 15 parts of NaOH, 5 parts of KMnO in parts by weight 4 And 80 parts of H 2 O mix well;

[0036] Step 2) Completely immerse the GH6783 alloy fracture in the above cleaning solution, boil it in a water bath, and obtain a pre-cleaned fracture after 130 minutes, and blow dry;

[0037] Step 3) Repeatedly stick the fracture with tape until the tape no longer sticks dirt;

[0038] Step 4) Brush the fracture with a brush soaked in acetone solution;

[0039] Step 5) Place the fracture completely in 19 parts HCl and 81 parts H in parts by weight 2 In O HCl solution, ultrasonic cleaning was performed for 4 min.

[0040] Step 6) Repeatedly stick the fracture with tape until the tape no longer sticks to the dirt, and scrub the fracture with a brush soaked in acetone solution.

[0041] Step 7) Use the fracture as the cathode and the...

Embodiment 2

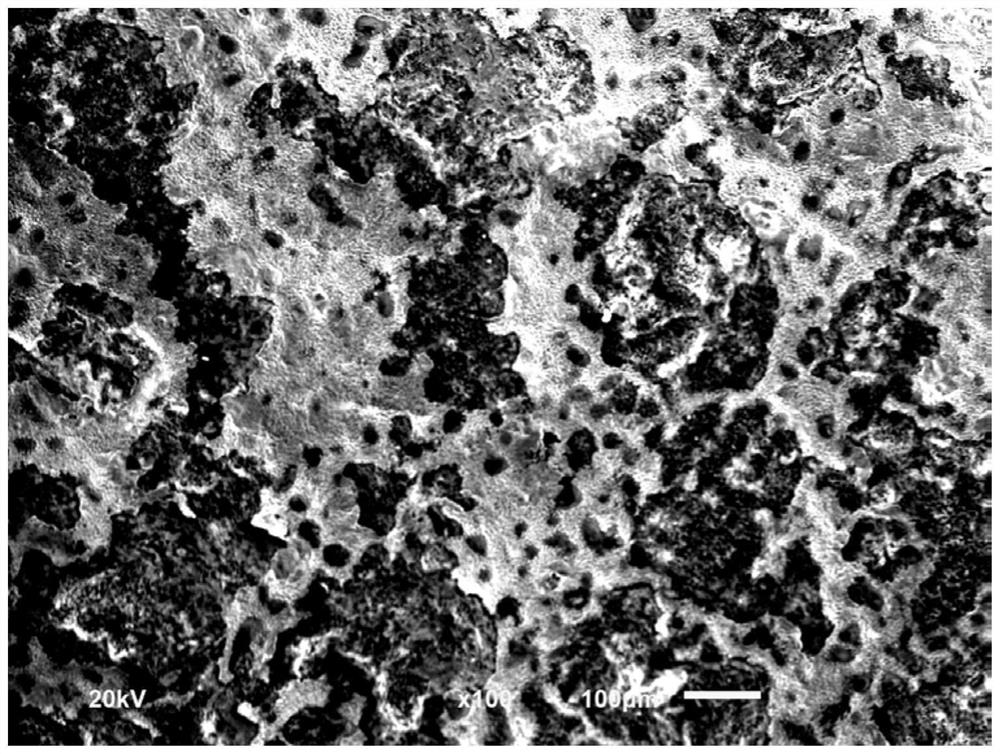

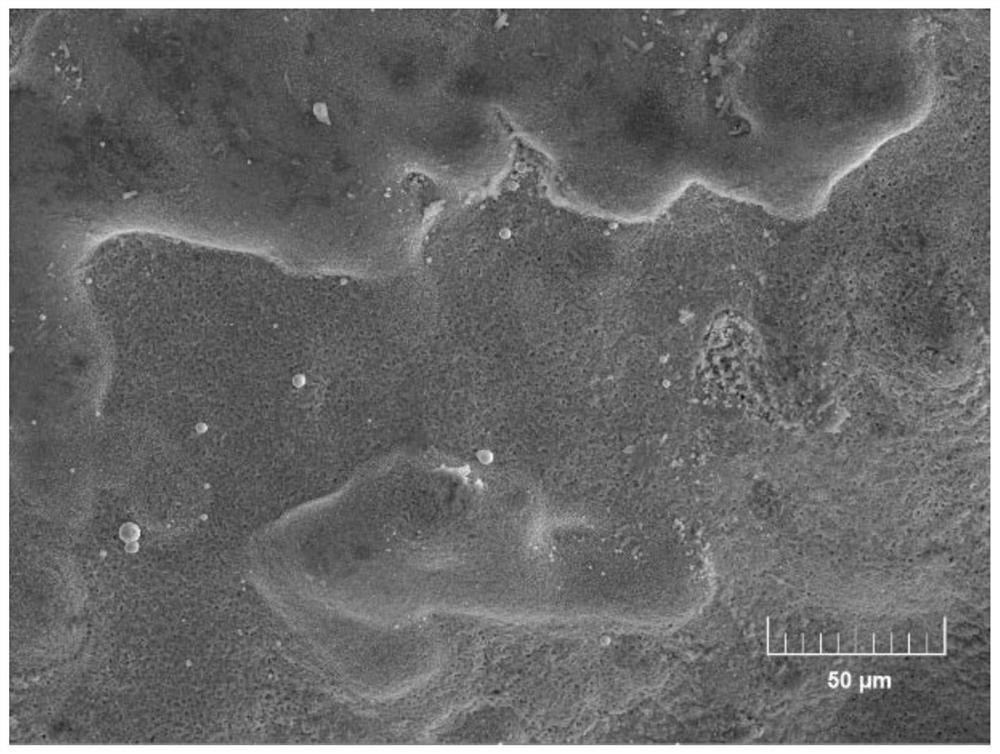

[0047] Example 2 see attached image 3 (Before cleaning) and attached Figure 4 (After cleaning), it can be seen that the method of the present invention can remove all oxides on the surface of the fracture, with little damage to the morphology of the fracture, and the cleaning effect is good.

Embodiment 3

[0048] Example 3 see attached Figure 5 (Before cleaning) and attached Image 6 (After cleaning), the comparison shows that no serious corrosion marks are found in the fracture tissue of the material before and after cleaning, and the dimple tissue in the fracture has clear characteristics. It can be seen that the method of the present invention will not damage the fracture for a long period of time. Or change the fracture morphology, the cleaning effect is better, which is helpful for fracture analysis.

[0049] The present invention first reduces the adhesion between the surface oxide and the substrate by alkaline boiling, and then repeats pasting and brushing to mechanically remove the oxide of the outer layer of Ni, then removes the oxide of Fe on the fracture surface by pickling, and then passes through the HCl cathode The electrolysis method removes the remaining oxides on the surface under the continuous scouring of acidic solution and cathode gas. Compared with simple pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com