Method of preparing flaccid anemone saponins W1 and W3 from rhizome of flaccid anemone

A technology of kunain and black medicinal materials, which is applied in the field of preparation of kusaponin W1 and W3, which can solve problems such as unfavorable safety management, serious environmental pollution, and high toxicity, and achieve the effects of reducing production costs, pollution, and health threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

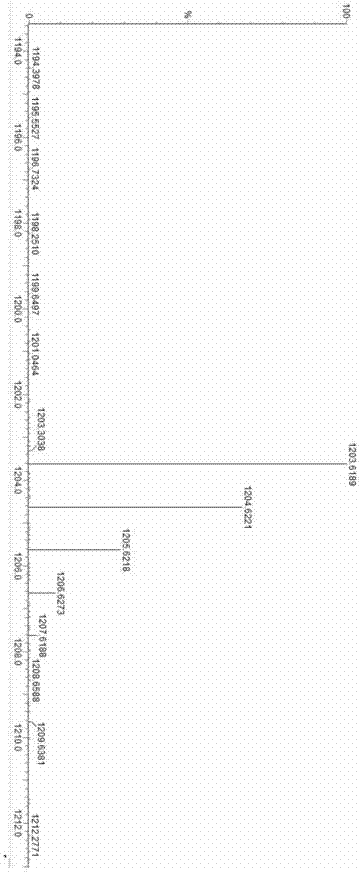

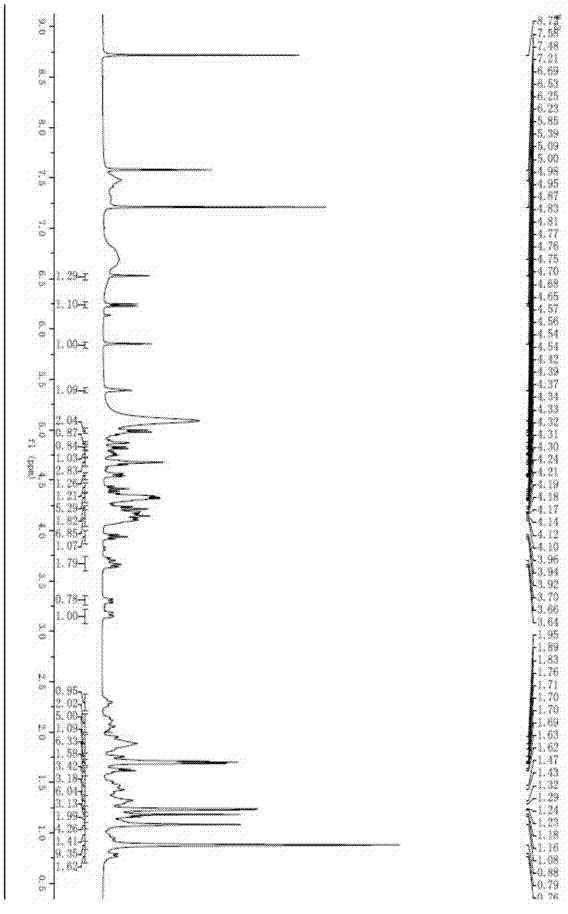

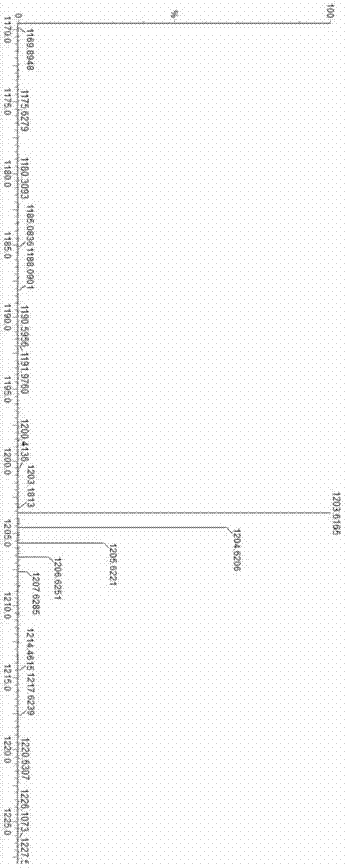

Image

Examples

Embodiment 1

[0040] 1) Take 1 kg of dried Diwu raw material and add it to the heating vessel. The raw material of Diwu medicinal material is generally in powder form.

[0041] 2) Pour 10L (10kg) of water into the heating vessel, heat and decoct for 1 hour, filter out the decoction, and keep the residue in the heating vessel.

[0042] 3) Repeat step 2) once, and combine the decoction filtered out each time.

[0043] 4) First, put the combined decoction on a D-101 macroporous resin column;

[0044] Then, carry out gradient elution with water, 10% ethanol, 50% ethanol and 95% ethanol solution in sequence, and achieve the purpose of removing impurities and cleaning through the elution treatment of water, 10% ethanol and 95% ethanol solution, and collect 50% ethanol wash The eluate after de-treatment,

[0045] Finally, the collected eluate was concentrated and dried under reduced pressure to obtain 62 g of the total saponins extract.

[0046] 5) Firstly, dissolve the obtained Diwu saponin ex...

Embodiment 2

[0056] 1) Take 1 kg of dried Diwu raw material and add it to the heating vessel. The raw material of Diwu medicinal material is generally in powder form.

[0057] 2) Pour 8L (8kg) of water into the heating vessel, heat and decoct for 3 hours, filter out the decoction, and keep the residue in the heating vessel.

[0058] 3) Repeat step 2) twice, and combine the decoction filtered out each time.

[0059] 4) First, put the combined decoction on the AB-8 macroporous resin column;

[0060] Then, carry out gradient elution with water, 25% ethanol, 80% ethanol and 95% ethanol solution in sequence, and achieve the purpose of removing impurities and cleaning through the elution treatment of water, 25% ethanol and 95% ethanol solution, and collect 80% ethanol wash The eluate after de-treatment,

[0061] Finally, the collected eluate was concentrated and dried under reduced pressure to obtain 58 g of the total saponins extract.

[0062] 5) Firstly, dissolve the obtained Diwu saponin e...

Embodiment 3

[0072] 1) Take 1 kg of dried Diwu raw material and add it to the heating vessel. The raw material of Diwu medicinal material is generally in powder form.

[0073] 2) Pour 5L (5kg) of water into the heating vessel, heat and decoct for 2 hours, filter out the decoction, and keep the residue in the heating vessel.

[0074] 3) Repeat step 2) twice, and combine the decoction filtered out each time.

[0075] 4) First, put the combined decoction on the AB-8 macroporous resin column;

[0076] Then, gradient elution was carried out with water, 35% ethanol, 75% ethanol and 95% ethanol solution in sequence, and the purpose of removing impurities and cleaning was achieved through the elution treatment of water, 35% ethanol and 95% ethanol solution, and the 75% ethanol solution was collected. The eluate after de-treatment,

[0077] Finally, the collected eluate was concentrated and dried under reduced pressure to obtain 60 g of the total saponins extract.

[0078] 5) Firstly, dissolve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com