PECVD (plasma enhanced chemical vapour deposition) film-coating system

A coating system and process system technology, applied in the field of vacuum coating, can solve the problems of long production cycle, complex equipment structure, high production cost, etc., and achieve the effect of simple and convenient installation and maintenance, simple and convenient transmission structure, and low mechanical precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

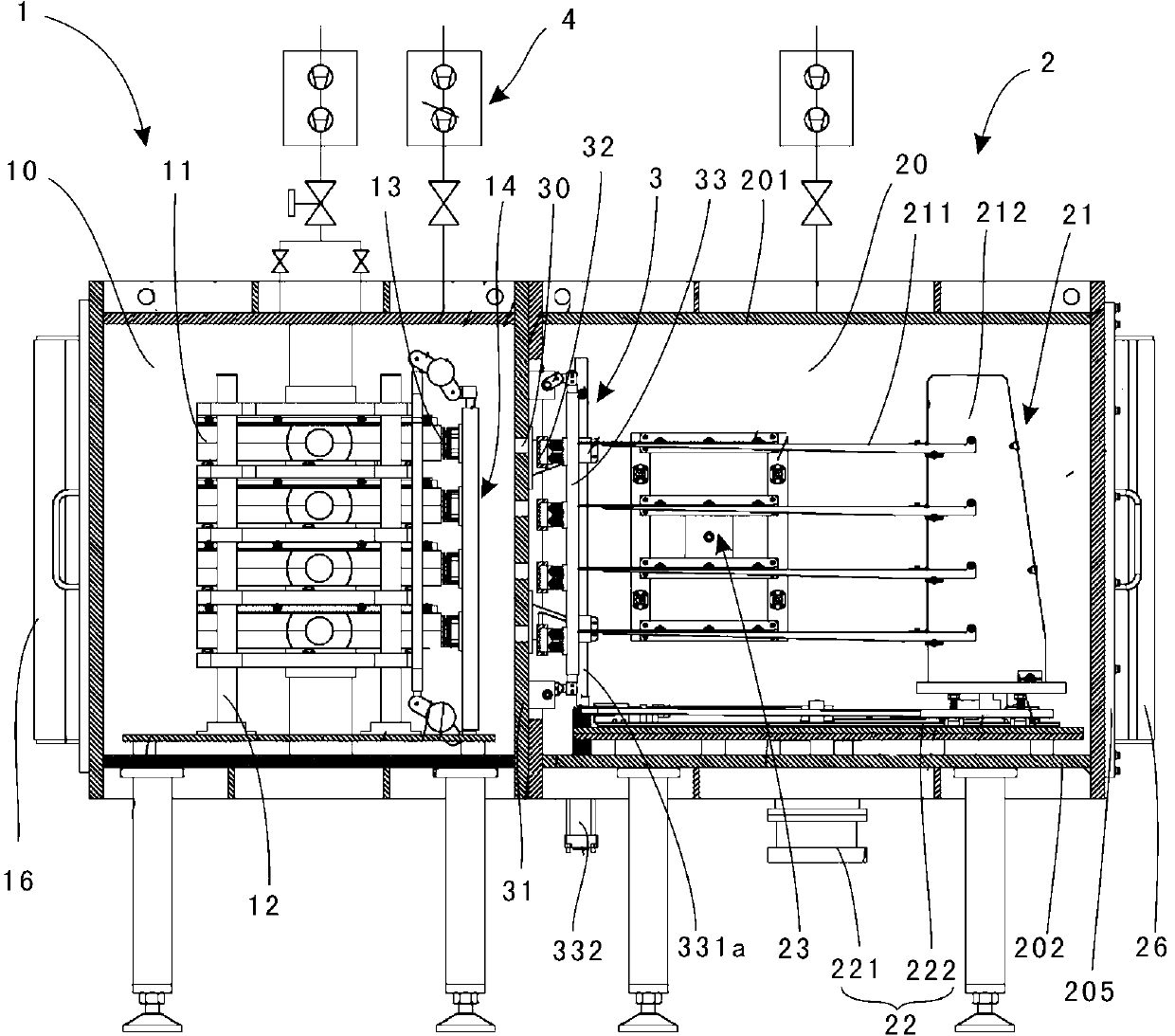

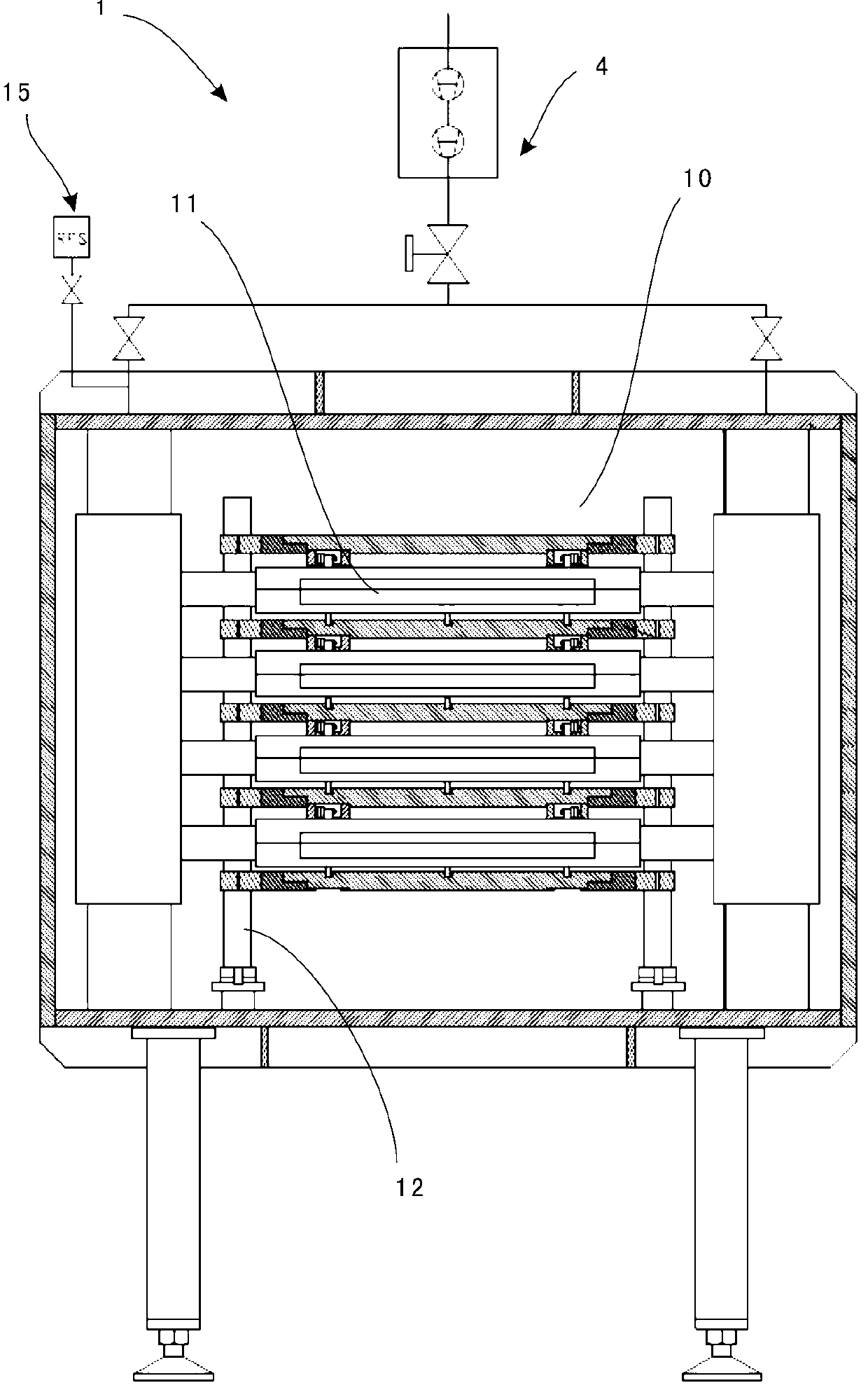

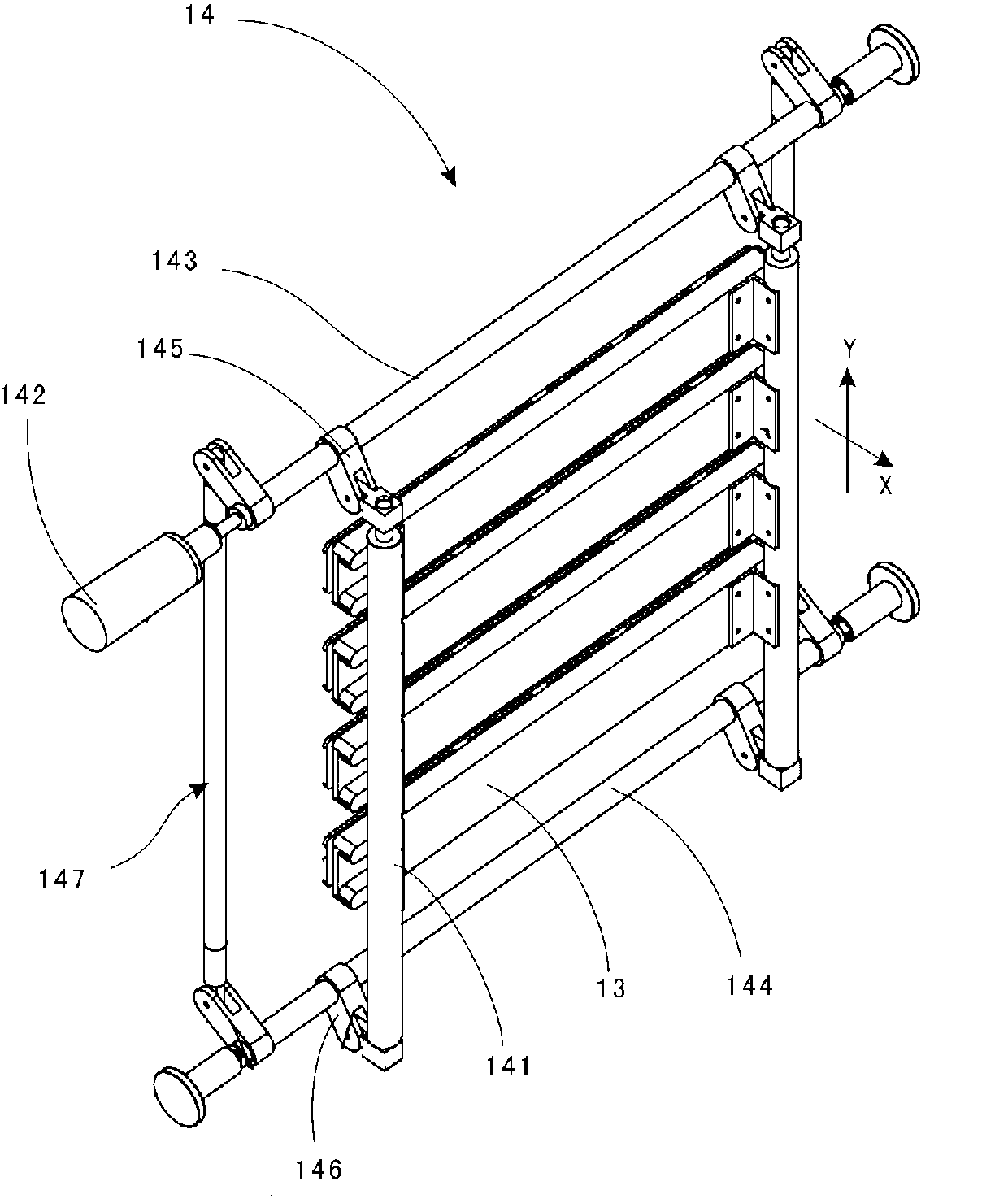

[0034] see Figure 1 to Figure 8 , a PECVD coating system provided by a preferred embodiment of the present invention, including a process system 1 , a loading and unloading system 2 , and a valve mechanism 3 . The process system 1 includes a process chamber 10 and at least one process reaction chamber 11 . The loading and unloading system 2 includes a loading and unloading chamber 20 and a transfer manipulator 21 . The valve mechanism 3 is arranged between the process chamber 10 and the loading and unloading chamber 20 for communication or isolation between the process chamber 10 and the loading and unloading chamber 20 . The transfer manipulator 21 is slidingly arranged between the loading and unloading chamber 20 and the process chamber 10 , and when the process chamber 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com