Powder spraying process and powder spraying equipment

A technology of powder spraying and equipment, applied in the direction of spray booth, spraying device, etc., can solve the problems of disconnected process, low speed upper limit, increased labor cost, etc., to achieve the effect of improving production efficiency, improving quality and ensuring the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

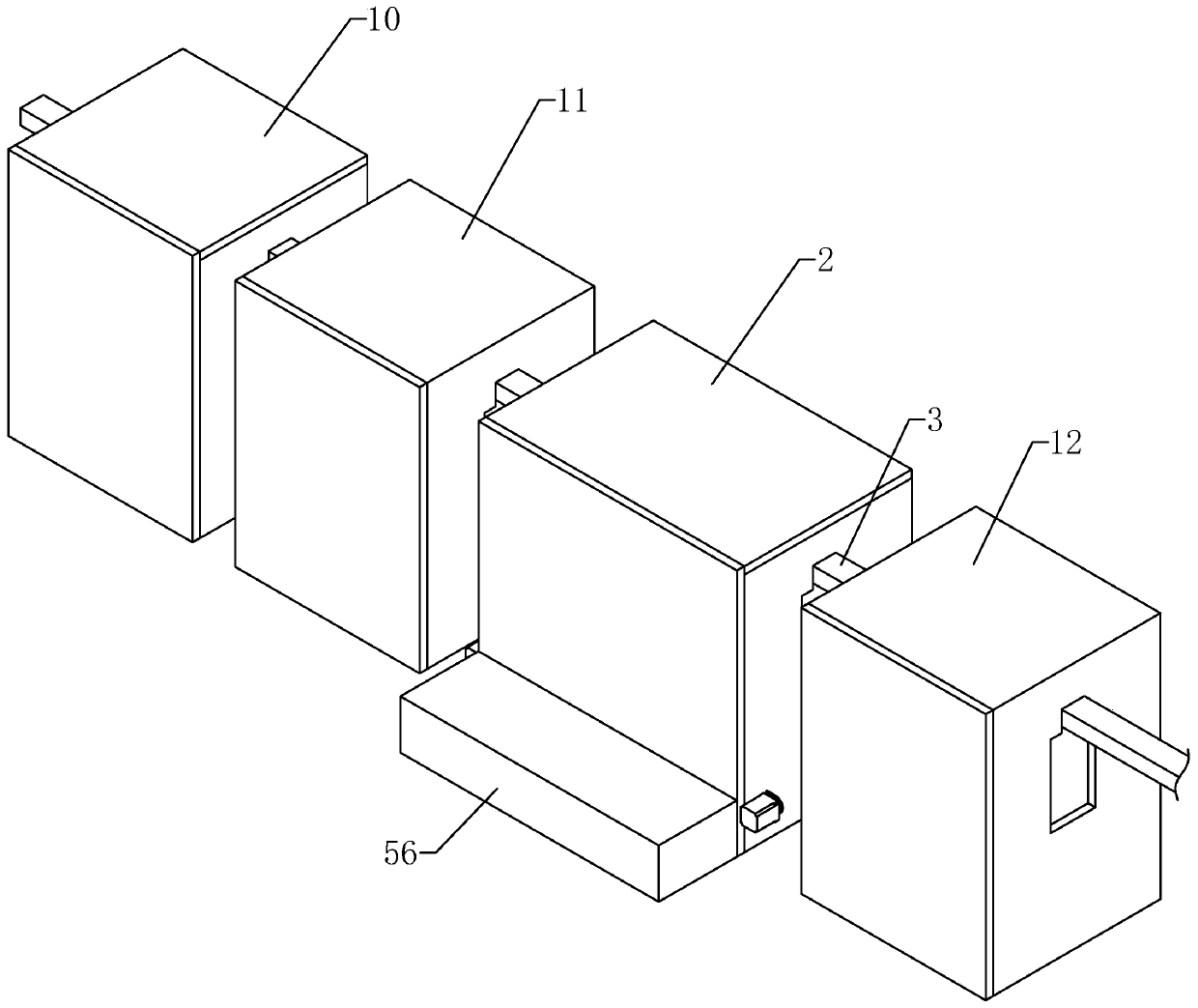

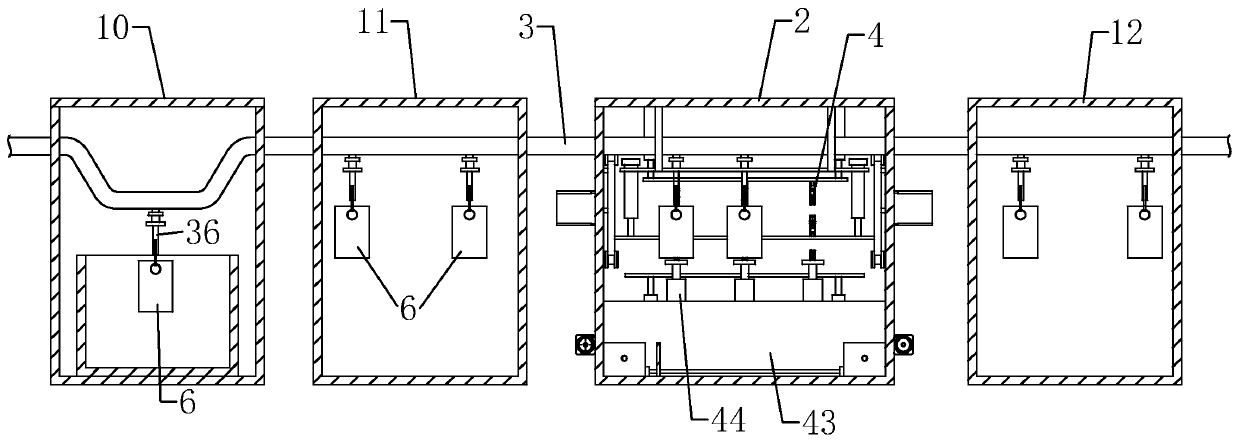

[0049] Embodiment 1, reference figure 1 and figure 2 , a powder spraying equipment, including a cleaning pool 10, a drying room 11, a powder spraying room 2 and a curing room 12 arranged in sequence. First the workpiece 6 enters the cleaning tank 10, and the acid solution in the cleaning tank 10 cleans the surface of the workpiece 6 to remove hand sweat and rust on the surface of the workpiece 6; then the workpiece 6 flows into the drying room 11, and the inner wall of the drying room 11 The resistance wire is embedded, and the temperature in the drying room 11 is increased by energizing the electronic wire, and the volatilization speed of the liquid on the surface of the workpiece 6 is accelerated; then the workpiece 6 enters the powder spraying chamber 2, and the powder spraying chamber 2 is used to spray the surface of the workpiece 6 paint, so that the workpiece 6 is separated from the air to prevent the workpiece 6 from rusting; finally the workpiece 6 enters the curing...

Embodiment 2

[0061] Example 2: Reference figure 2 and Figure 5 , a powder spraying process, comprising the following steps:

[0062] 1. First, the surface of the workpiece 6 is treated to remove welding slag and solid foreign matter on the surface of the workpiece 6 to ensure the smoothness of the surface of the workpiece;

[0063] 2. Next, put the workpiece 6 into the cleaning pool 10 for cleaning, and deeply remove the rust and sweat stains on the surface of the workpiece 6;

[0064] 3. Then the workpiece 6 is transferred to the drying room 11 and dried in the drying room 11;

[0065] 4. Then the workpiece 6 enters the powder spraying chamber 2 for powder spraying. The powder spraying steps are as follows:

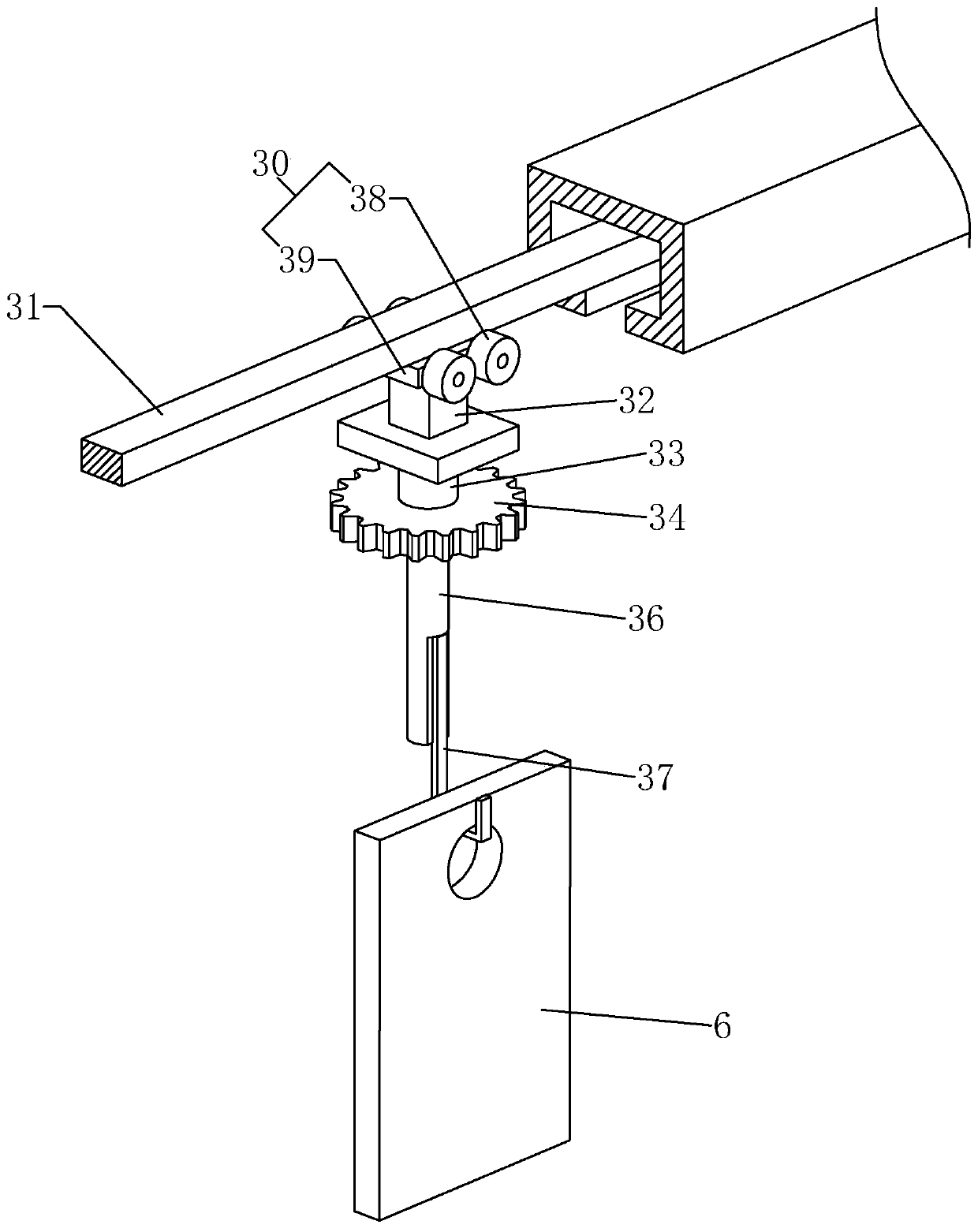

[0066] a. The workpiece 6 enters the powder spraying chamber 2, and the gear 34 meshes with the rack 35 at the same time. The workpiece 6 rotates on its own during the movement, so that the workpiece 6 rotates. At the same time, the powder spray gun 4 sprays powder on the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com