Circular deep foundation ditch concrete pile arranging support and major structure inversing construction method

A technology of the main structure and construction method, which is applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of unsuitability for complex geological conditions and high construction costs, achieve protection from disturbance, reduce the cost of construction measures, and reduce excavation area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The construction method of concrete row pile support and main structure of circular deep foundation pit is characterized in that the steps are as follows:

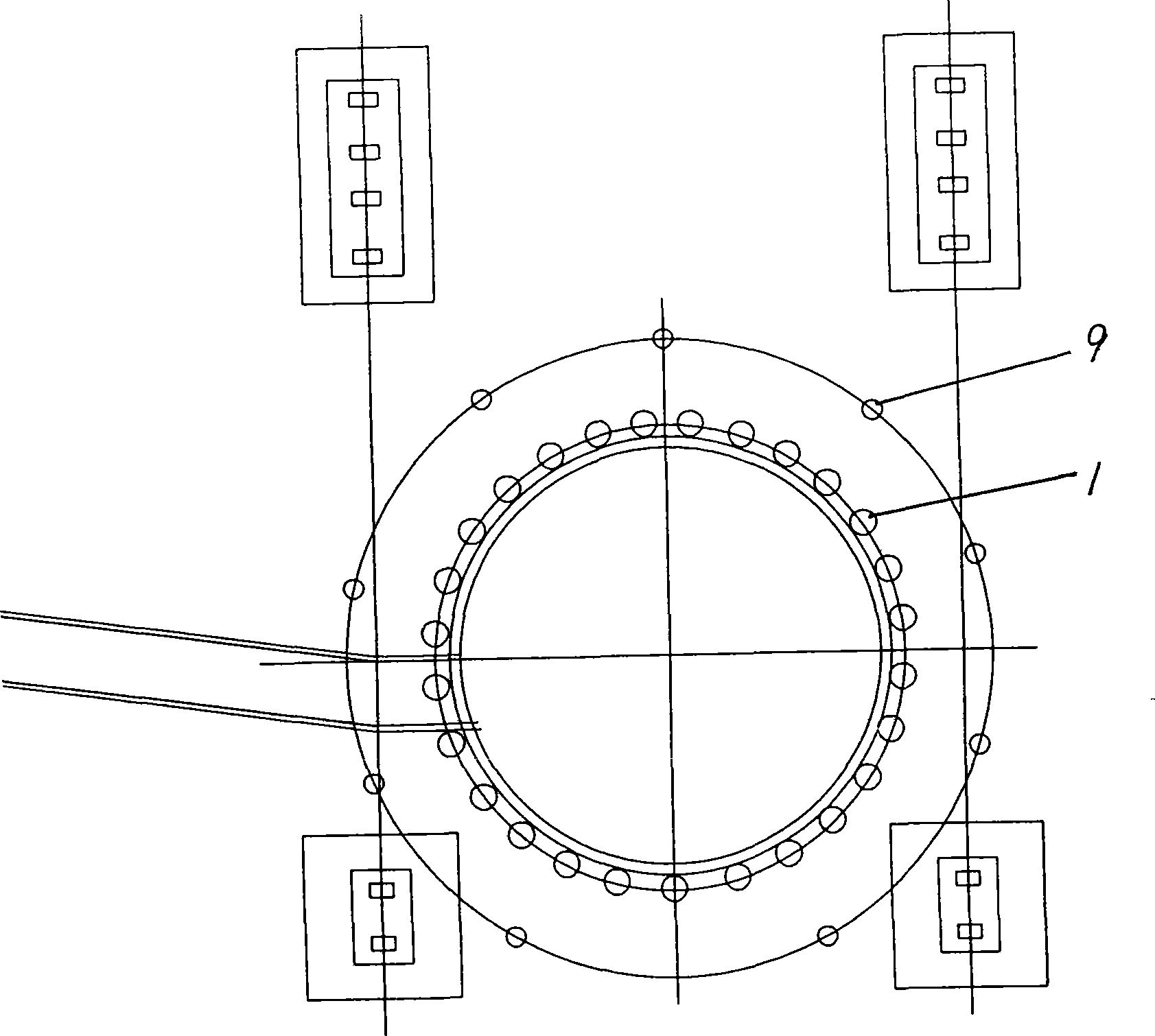

[0027] 1) With the center of the foundation pit as the center, a row of piles 1 is uniformly arranged outside the main structure position;

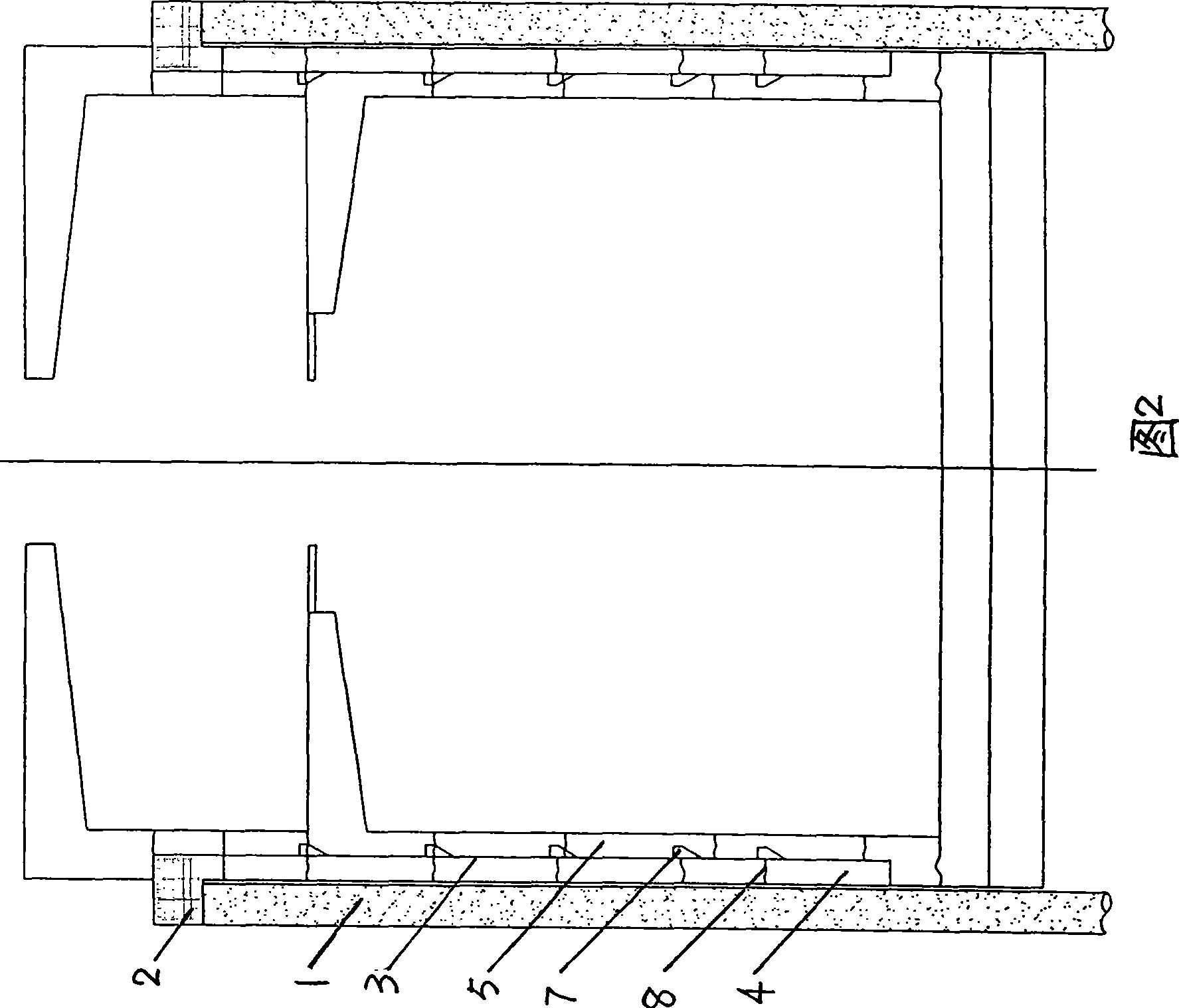

[0028] 2) The top of the row of piles is poured with a crown beam 2 connecting the piles as a whole, the crown beam 2 extends into the foundation pit, and the length of the crown beam 2 extending into the pit is equal to the thickness of the outer layer 4 of the main structure;

[0029] 3) Leave a vertical construction joint 3 in the middle of the thickness of the main structure, divide the main structure into inner and outer two layers of construction;

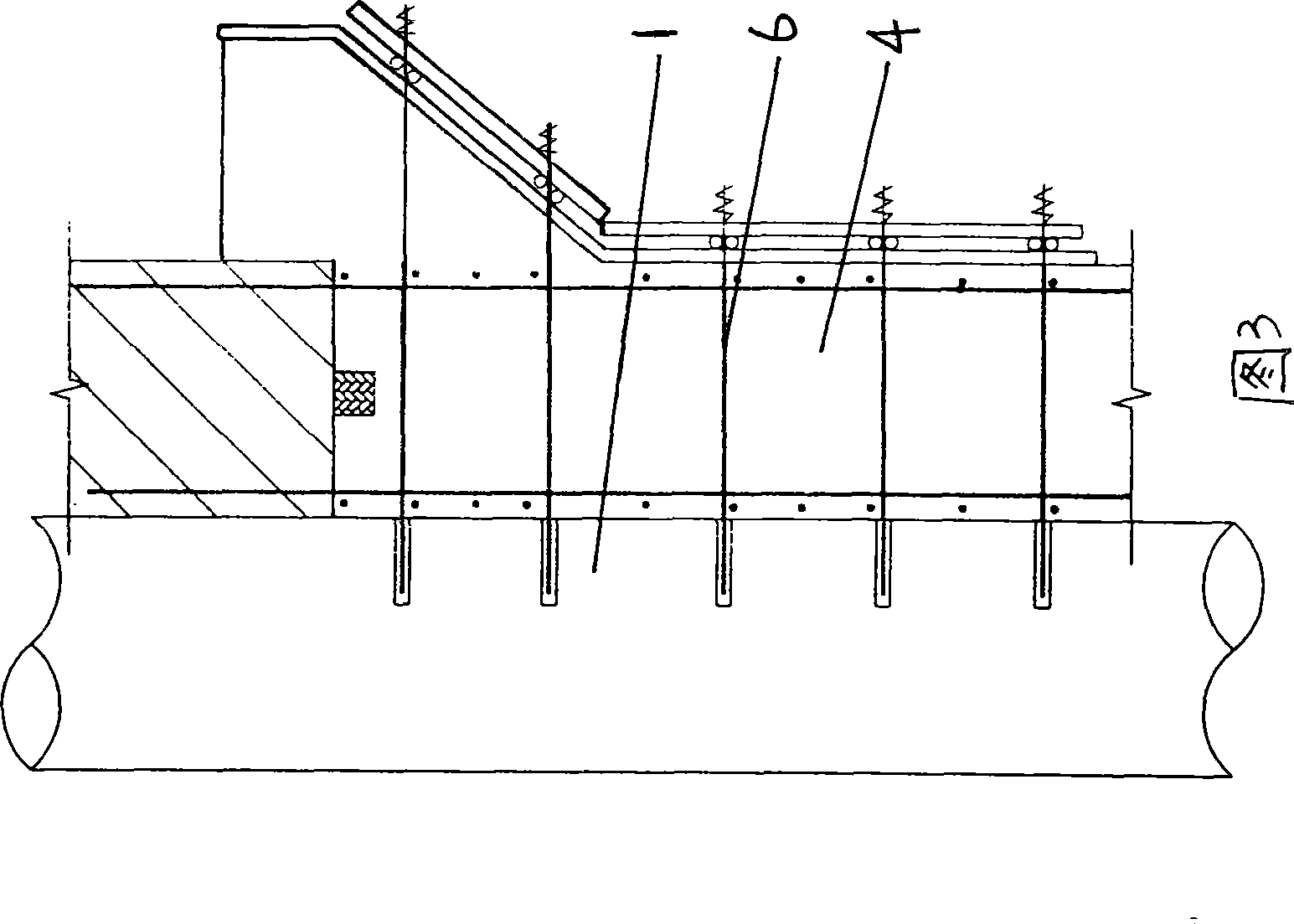

[0030] 4) Excavation of the foundation pit of the first section, reverse construction of the outer layer of the main structure of the first section, and crown beams connecting the outer layer 4 of the main structure of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com