Detergent putting structure and washing machine

A detergent injection and washing drum technology, applied in the field of washing machines, can solve the problems of easy water storage in pipelines and water outlets, and achieve the effects of easy market promotion, low failure probability, and strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

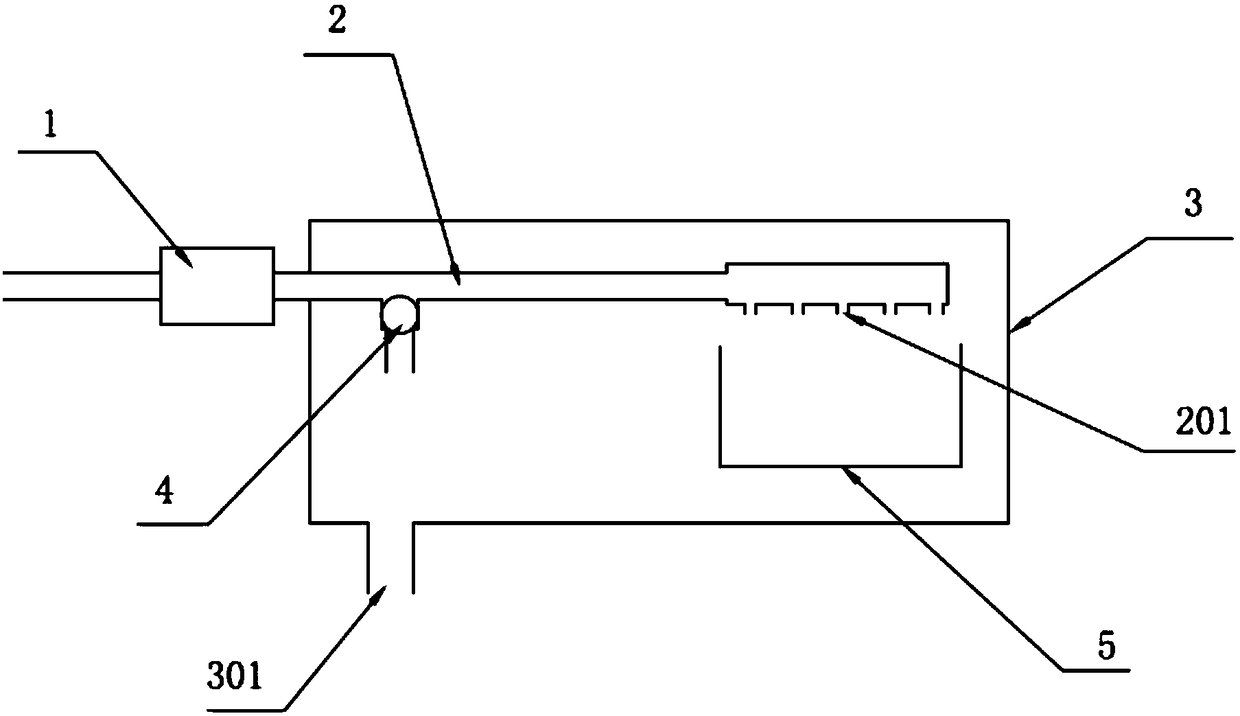

Embodiment 1

[0037] A detergent dispensing structure, comprising a water inlet valve 1, a water inlet pipeline 2 and a dispensing device 3, one end of the water inlet pipeline 2 is connected to the water outlet of the water inlet valve 1, and the other end extends to the inside of the dispensing device 3 and is provided with Waterway exit 201;

[0038] A ventilation structure located inside the dispensing device 3 is provided between the water inlet valve 1 and the waterway outlet 201. The ventilation structure uses the hydraulic pressure difference formed when the water inlet valve 1 is closed to empty the water in the water inlet pipeline 2 and the waterway outlet 201.

[0039] In the ventilation structure, the ventilation channel is closed when the water inlet valve 1 is opened, and the ventilation channel is opened when the water inlet valve 1 is closed, or the ventilation channel remains normally open.

[0040] The ventilation structure is a one-way check valve 4 or an air vent 6, and...

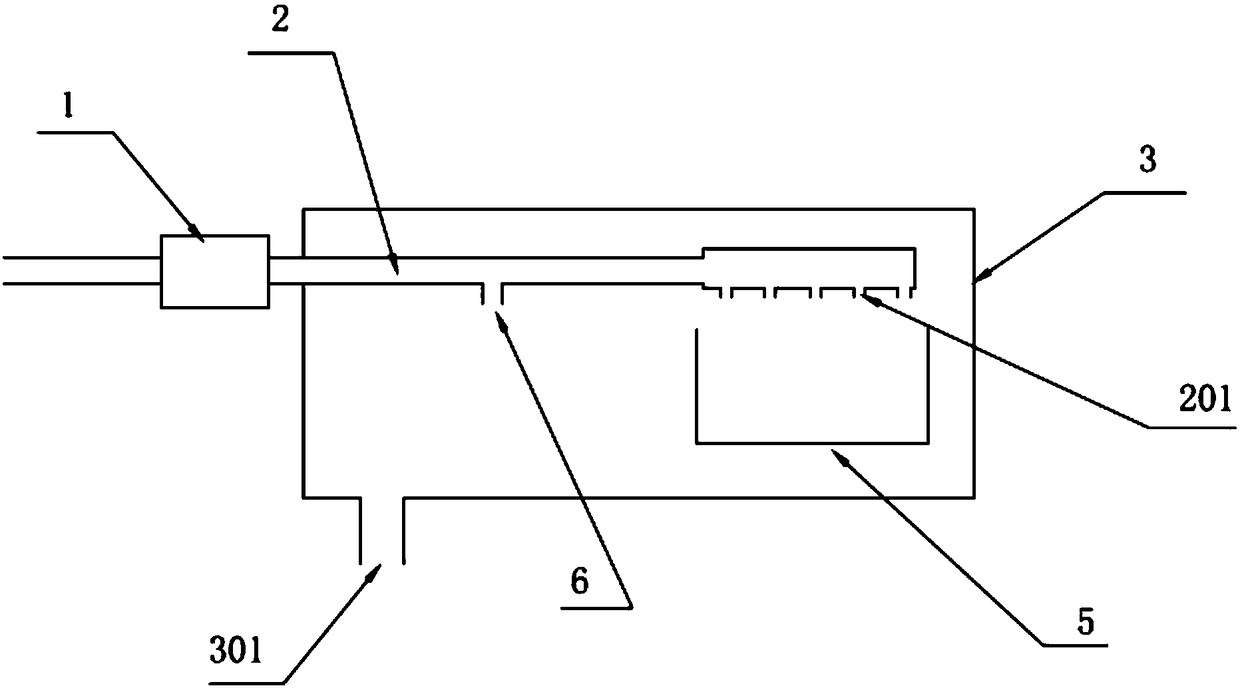

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is that the ventilation structure is different, and the ventilation structure adopted in this implementation is the ventilation port 6, see the attached figure 2 .

[0059] A detergent dispensing structure, comprising a water inlet valve 1, a water inlet pipeline 2 and a dispensing device 3, one end of the water inlet pipeline 2 is connected to the water outlet of the water inlet valve 1, and the other end extends to the inside of the dispensing device 3 and is provided with Waterway exit 201;

[0060] A ventilation structure located inside the dispensing device 3 is provided between the water inlet valve 1 and the waterway outlet 201. The ventilation structure uses the hydraulic pressure difference formed when the water inlet valve 1 is closed to empty the water in the water inlet pipeline 2 and the waterway outlet 201.

[0061] In the ventilation structure, the ventilation channel is closed when the water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com