Sealed automatic cutting machine for cutting black metal

A ferrous metal, closed technology, applied in the direction of metal sawing equipment, metal processing equipment, sawing machine accessories, etc., can solve the problems of polluted workshop production environment, low degree of automation, poor processing consistency, etc., and achieve processing adaptability Good, easy to use and maintain, reduce noise and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

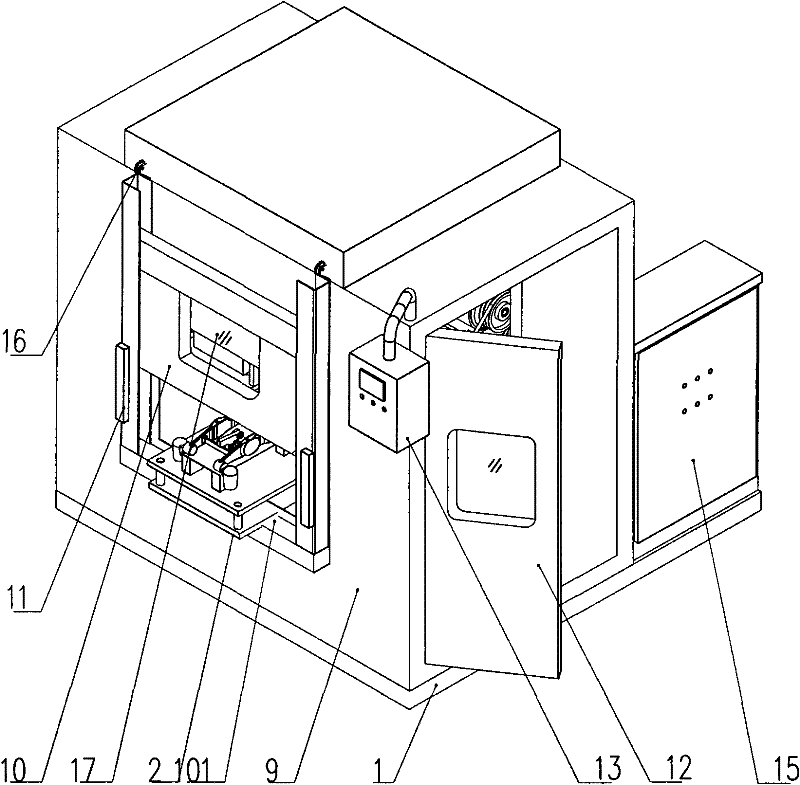

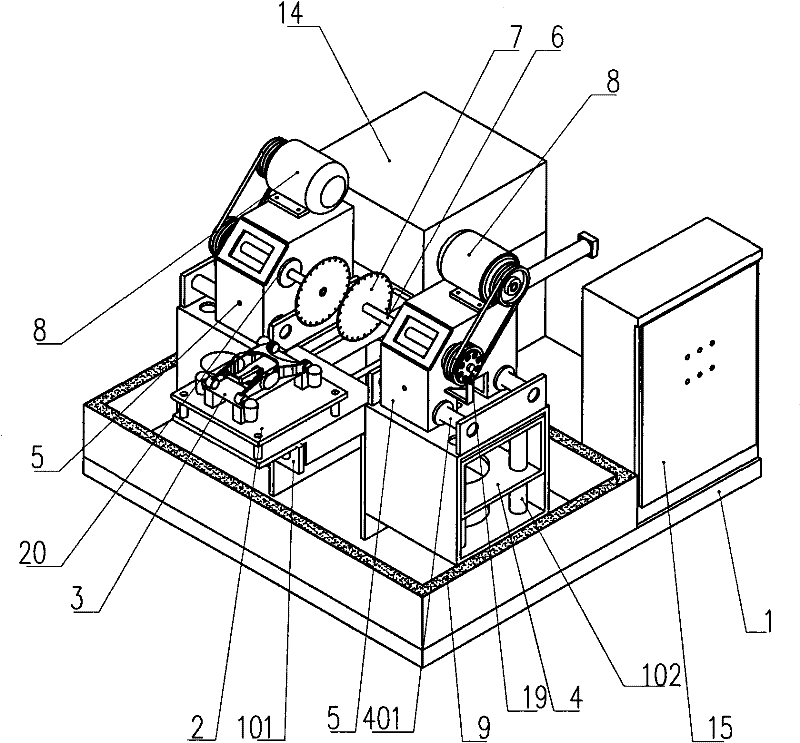

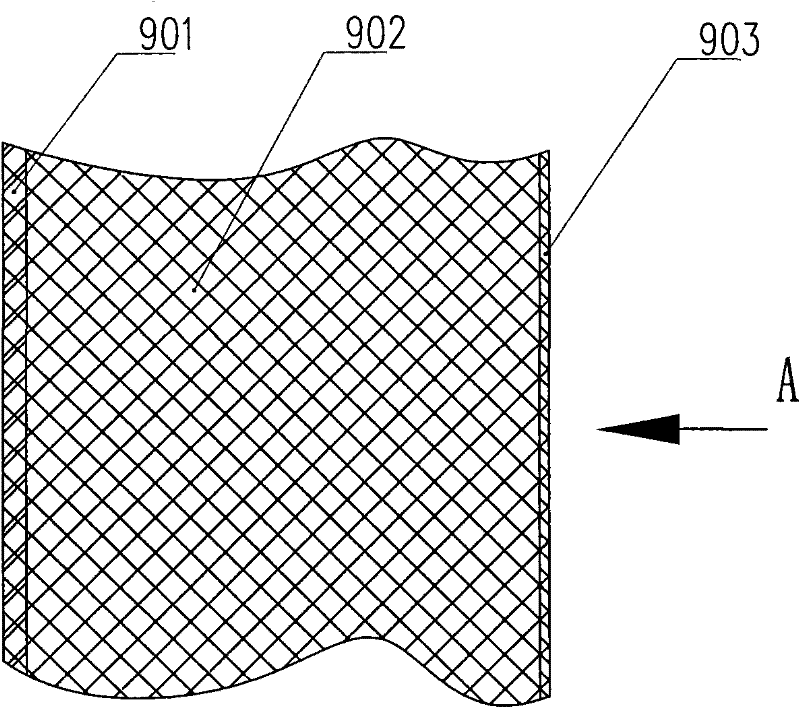

[0018] Depend on figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a closed automatic cutting machine for cutting ferrous metals, which includes an organic base 1, an X-direction work slide 2, an X-direction hydraulic cylinder, a hydraulic special fixture 3, a Y-direction work slide 4, a Y-direction hydraulic cylinder, Z-direction working slide 5, Z-direction hydraulic cylinder, spindle 6, high-alloy composite tool 7, motor 8, soundproof room 9, visible protective door 10, safety light curtain sensor 11, inspection door 12, display screen and button box 13 , a hydraulic station 14 and an electric control cabinet 15, the X-direction working slide 2 is movable on the X-direction slideway 101 of the machine base 1, one end of the X-direction hydraulic cylinder is fixed on the machine base 1, and the other end is connected to the X-direction The working slides 2 are connected, and the machine base 1 is welded by heavy-duty steel. 3 is customized according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com