Ventilating air-conditioning system of large welding workshop

A technology for welding workshops and air-conditioning systems, applied in air-conditioning systems, ventilation systems, space heating and ventilation, etc., can solve the problems of imperfect operation management, failure to achieve ventilation effects, and high concentrations of harmful substances, reduce temperature, ensure The effect of environment and safety, comfortable thermal environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, but not only limited to the following examples.

[0022] Large-scale welding workshop ventilation and air conditioning system mainly includes:

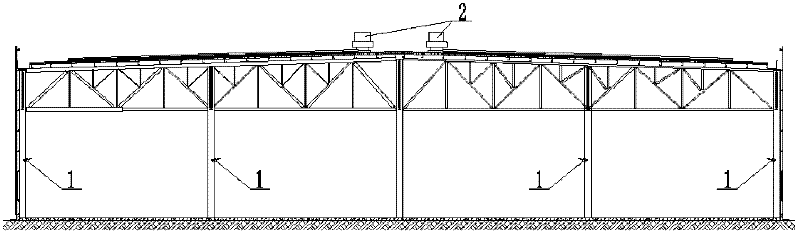

[0023] 1) Fully ventilated part

[0024] An induction fan 1 with multi-angle injection is installed on each span in the workshop, and the corresponding roof exhaust fan 2 is arranged on the roof. The ventilation air flow formed by the induction fan and the roof exhaust fan workshop is an induced unidirectional flow;

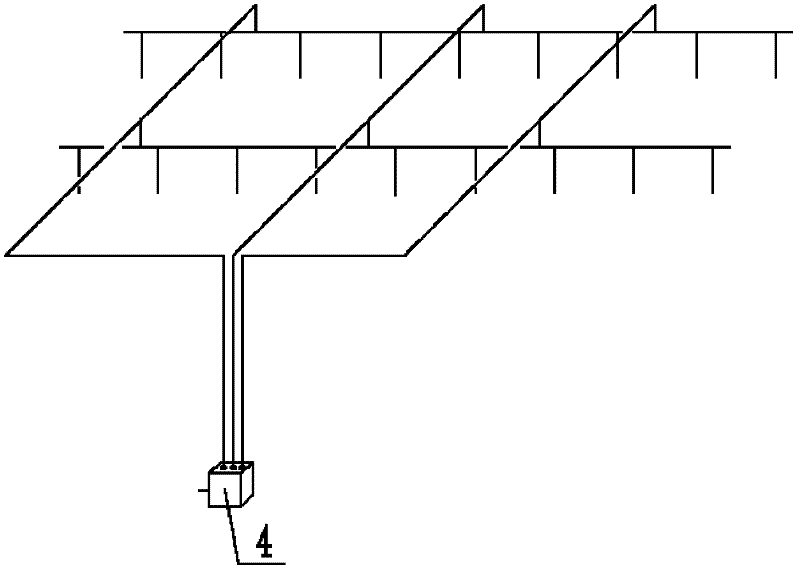

[0025] 3) Work station air conditioner

[0026] The air-conditioning terminal 5 installed on each working position in the workshop, the air-conditioning terminal communicates with the air-conditioning chassis through the air supply pipe;

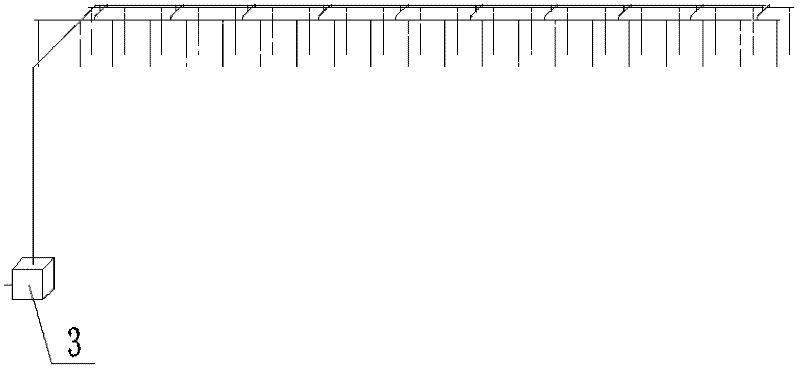

[0027] 3) Part of local ventilation

[0028] The local exhaust hood is arranged above the welding frame in the workshop, and the local exhaust hood is connected with the fan box through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com