Car-type heat treatment furnace

A heat treatment furnace, trolley-type technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of insufficient satisfaction, uneven temperature, high heat preservation, etc., to achieve high-quality heat treatment performance, improve production efficiency, and heat preservation effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the principle and structure of the present invention, the preferred embodiments of the present invention are now described in detail in conjunction with the accompanying drawings, but the embodiments are only for illustration and explanation, and cannot be used to limit the scope of patent protection of the present invention.

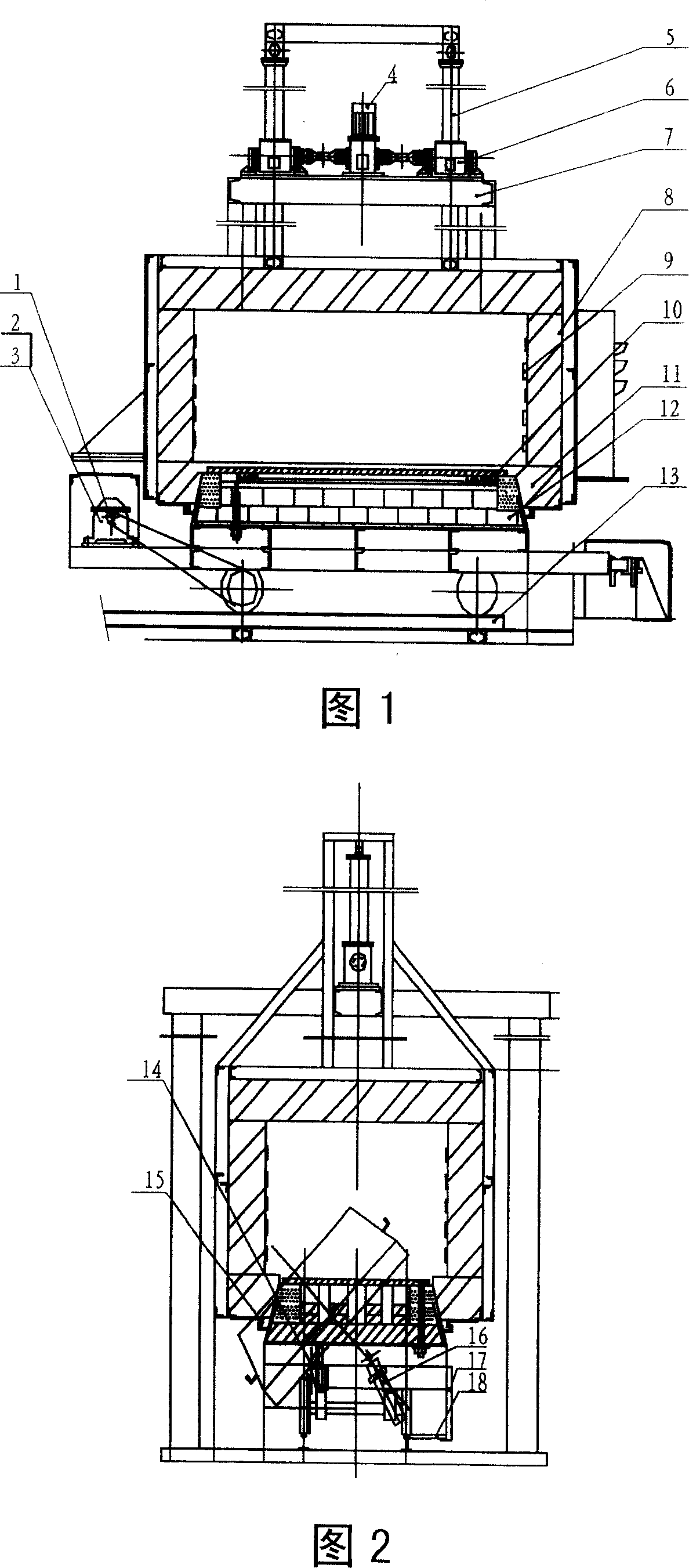

[0027] Fig. 1 schematically shows a front sectional view of a traveling mechanism according to an embodiment of the present invention, and Fig. 2 schematically shows a side sectional view of the bottom of the traveling mechanism shown in Fig. 1 in an overturned state, in Fig. 1 And in Fig. 2, parts such as the power supply, fan and the like that are irrelevant to the invention point of the present invention are omitted. As shown in the drawings, the present invention provides a trolley-type heat treatment furnace, which includes: a furnace cover 8; a resistance band 9 arranged on the inner wall around the furnace cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com