Method and apparatus for processing transparent conductive glass surface by dry ice particle spraying technique

A technology of transparent conductive glass and technical treatment, which is applied in the field of polishing and cleaning of transparent conductive glass to achieve the effects of reducing discharge, saving water and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

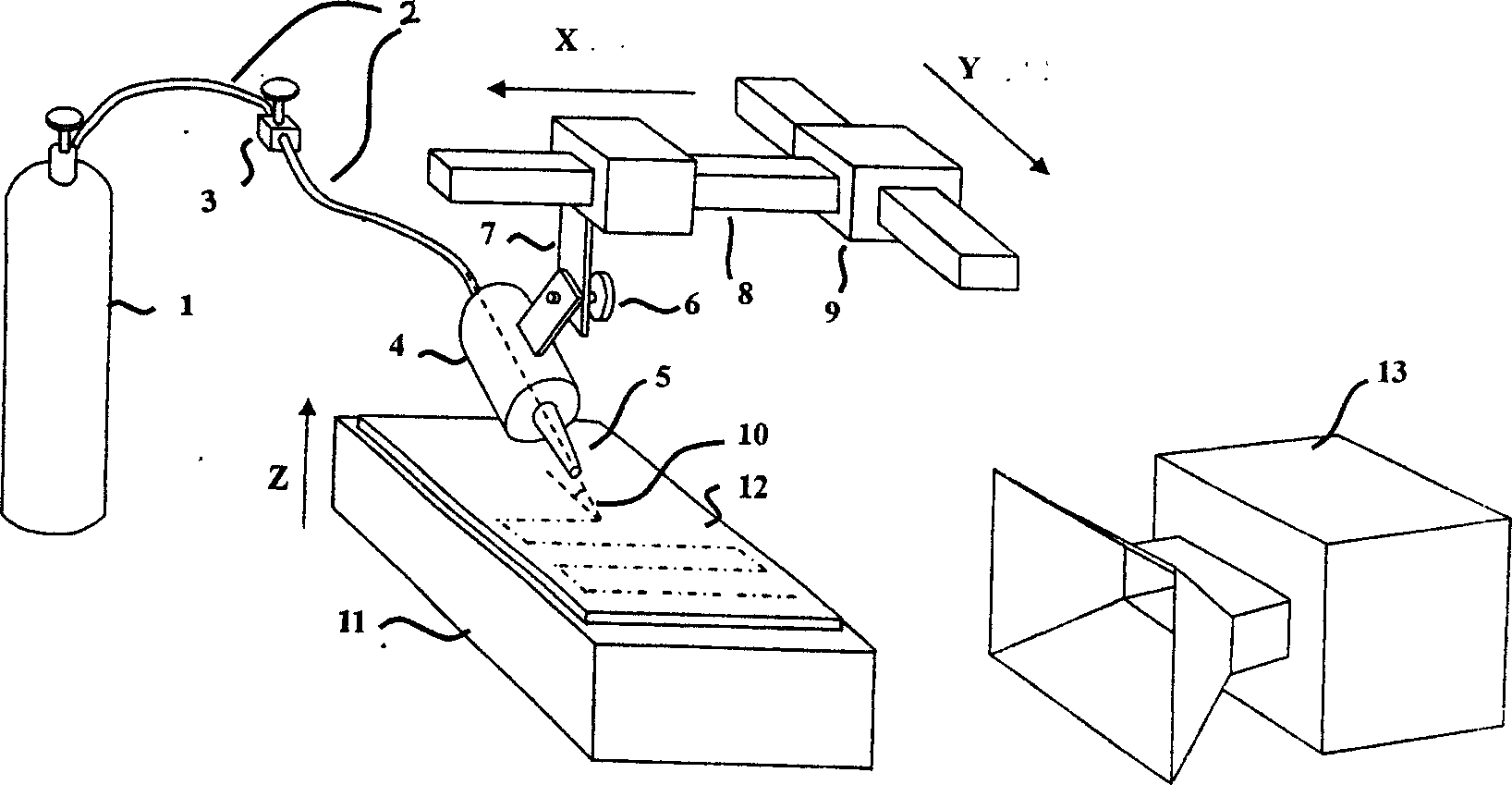

[0019] In the present invention, the pressure of the high-pressure carbon dioxide gas is greater than 6 MPa, the inner diameter of the nozzle 5 is less than 0.7 mm, and the diameter of the generated dry ice particles is less than 100 microns. The incident angle between the dry ice particle jet and the transparent conductive glass substrate is 30 to 60 degrees, and the jet length of the dry ice particle is 30 to 100 mm.

[0020] The operating steps of the present invention are as follows:

[0021] 1. Place the glass 11 that needs to be polished or cleaned and coated with a transparent conductive film on the Z-direction translation platform 10, with the transparent conductive film facing upwards, and adjust the Z-direction translation platform 10 so that the distance between the surface of the transparent conductive glass and the nozzle 5 meets Processing requirements.

[0022] 2. Adjust the X-direction translation table 8 and the Y-direction translation table 9 so that the noz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com