Technique for treating phenol/anisole-containing production wastewater

A technology for the production of waste water and treatment process, which is applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems that there are no relevant reports on the treatment process of phenolic waste water, and achieve low cost , The catalytic effect is obvious, and the effect of reducing the content of anisole and COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

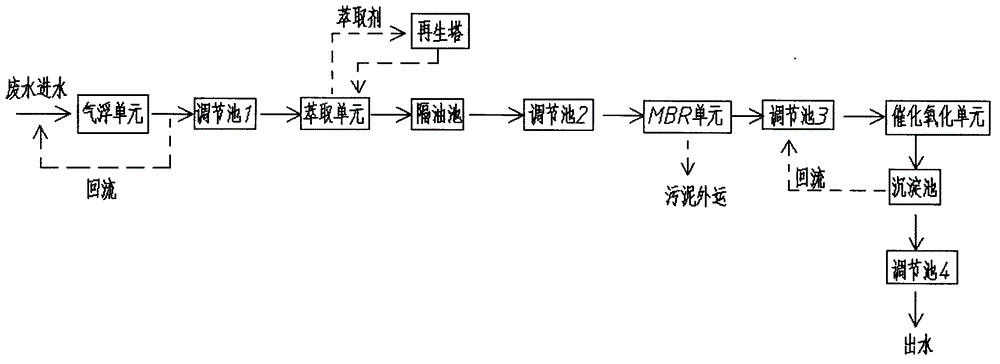

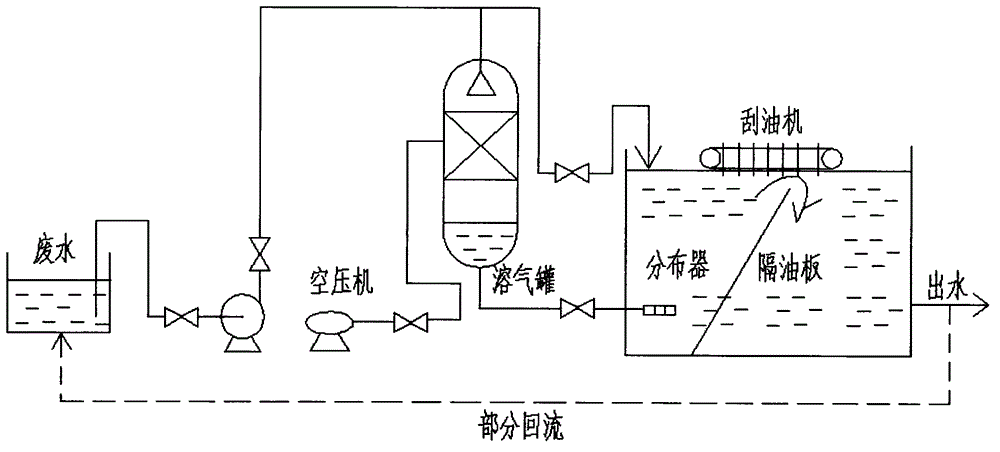

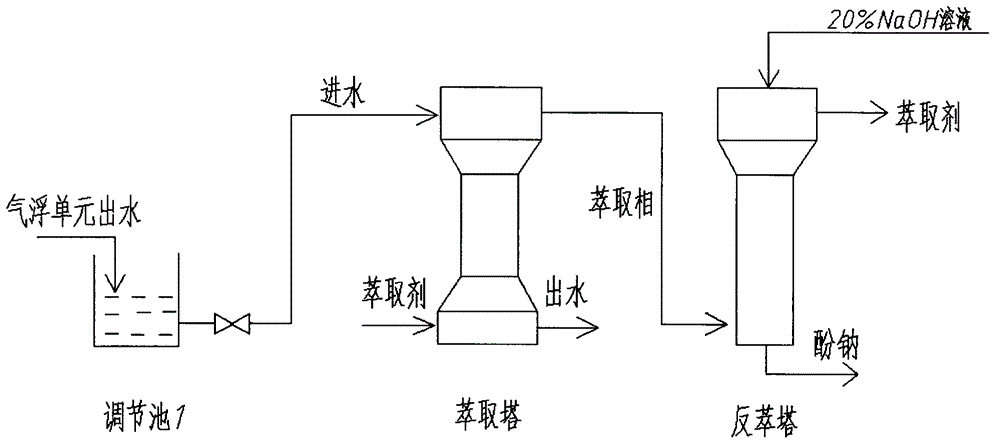

[0026] The raw water composition of wastewater is COD: 49000mg / L, volatile phenol: 6000mg / L, methanol: 4500mg / L, anisole: 1400mg / L. The waste water first enters the air flotation unit. The concentration of the air flotation agent polyaluminium chloride is 500mg / L. The bottom of the air flotation unit is fed with a mixture of soda and water from a pressurized dissolved air tank. The pressure of the dissolved air tank is 0.2MPa, and the waste water is in the air flotation tank. The residence time is controlled at 3h. After the wastewater is treated by the air flotation unit, it enters the adjustment tank 1, and the pH is adjusted to 5. The effluent from the adjustment tank 1 enters the top of the multi-stage extraction tower through the centrifugal pump. The effective extraction stages of the extraction tower are 8, and the extraction agent enters the extraction tower through the magnetic pump. At the bottom, the extraction oil-water ratio is controlled at 1:5, and the compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com