Method for preparing platinum nanometer perforated electrodes with electrodeposition

A porous electrode and platinum nanotechnology, applied in the field of material preparation and electrochemical detection, can solve the problems of disappearance of glucose response signal, unsuitable for mass production, complex electrode preparation methods, etc., and achieve easy implementation, small quantity, and good catalytic effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

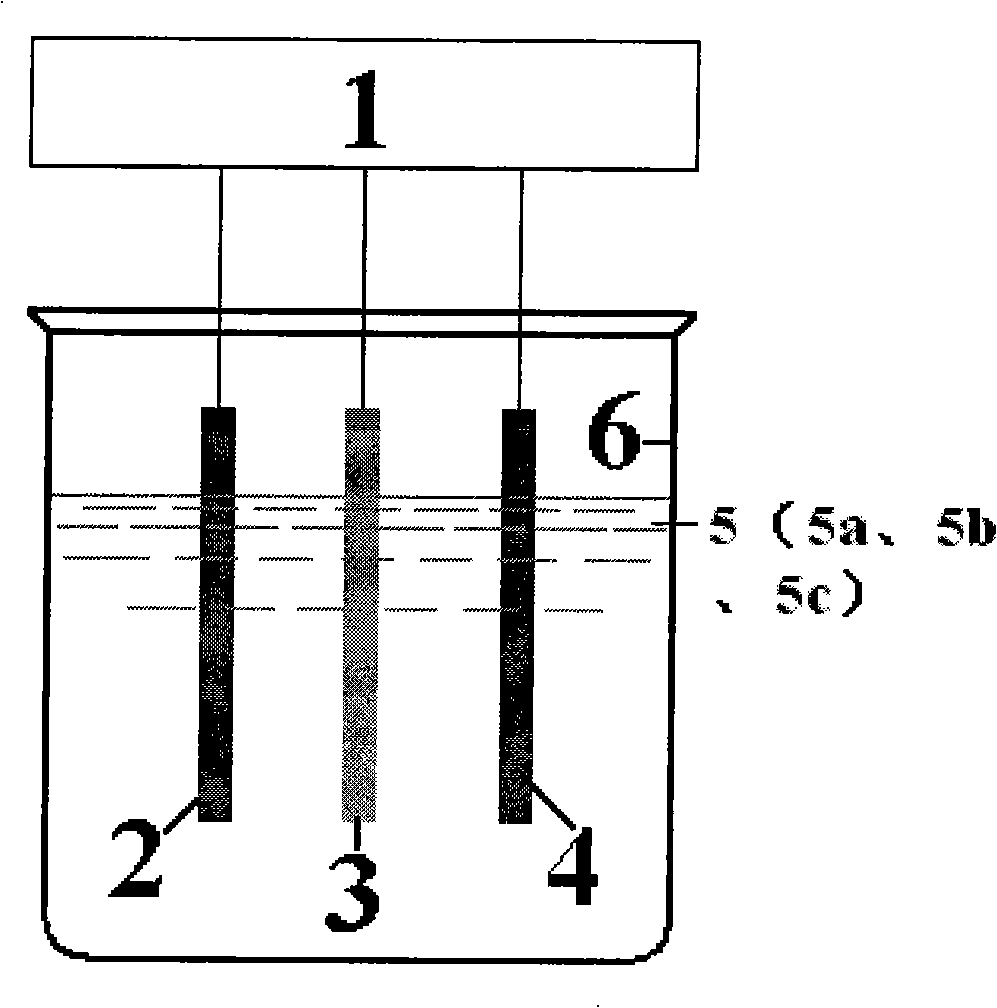

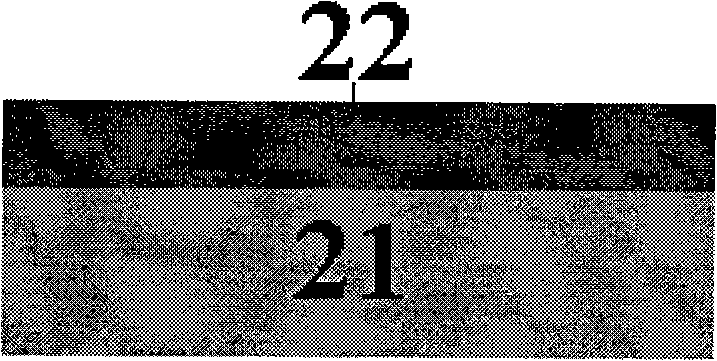

[0032] In the first step, the substrate 21 of the working electrode 2 is a platinum disc; in the third step, the constant voltage provided by the electrochemical workstation 1 is 70 mV, the average deposition thickness of the PtCu alloy film 22 is 100 nm, and the electrodeposition time is 4min.

Embodiment 2

[0034] Except for the following differences, the rest are the same as in Example 1.

[0035] In the third step, the constant voltage provided by the electrochemical workstation 1 was 60 mV, and the electrodeposition time was 5 min.

Embodiment 3

[0037] Except for the following differences, the rest are the same as in Example 1.

[0038] In the third step, the constant voltage provided by the electrochemical workstation 1 was 80 mV, and the electrodeposition time was 3 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com