Preparation method of mesoporous carbon nitride loaded precious nano particle

A technology of mesoporous carbonized nitrogen and nano-particles, which is applied in the field of materials-related preparation methods, can solve the problems of mesoporous materials, weak force, and easy falling off of metal precursors, and achieve good catalytic effects and save raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

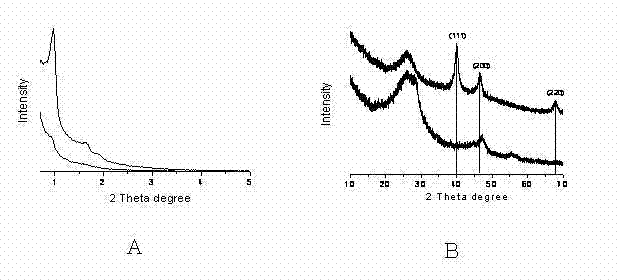

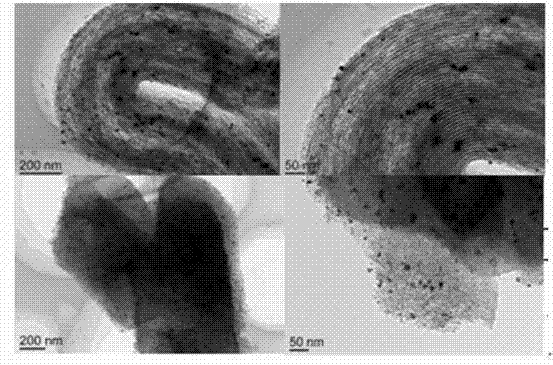

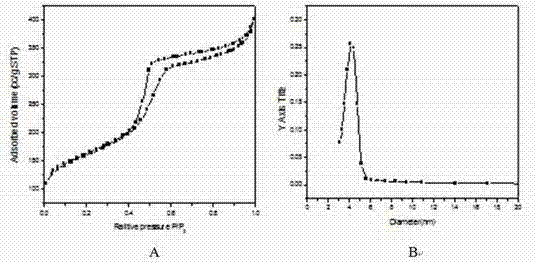

[0026] a. Synthesis of ordered mesoporous nitrogen carbide materials

[0027] Mix 1g of SBA-15, 6g of carbon tetrachloride, and 2.7g of ethylenediamine in a certain proportion, heat and reflux at 60°C for 4h, dry overnight, then place it in a quartz tube, and purify at 600°C and 40ml / min Heating in a nitrogen atmosphere, keeping the material for 2 hours to carbonize the material, and obtaining a brown-black powder; stirring the obtained brown-black powder with 50 mL of 25% hydrofluoric acid solution for 3 hours, washing with deionized water and ethanol several times, and drying to obtain the obtained Ordered mesoporous nitrogen carbide materials.

[0028] b, the preparation of alkylated halide ion compound

[0029] Take 0.5g of ordered mesoporous nitrogen carbide material, dissolve it in 100mL of DMF solution, then add 5.6g of methyl iodide, heat to reflux at 100°C for 0.5h, filter with suction, wash the obtained solid with distilled water and acetone, and then dry it.

[00...

Embodiment 2

[0035] a. Synthesis of ordered mesoporous nitrogen carbide materials

[0036] Mix 1g of SBA-15, 6g of carbon tetrachloride, and 2.7g of ethylenediamine in a certain proportion, heat and reflux at 100°C for 4 hours, dry overnight, then place it in a quartz tube, and purify at 300°C and 40ml / min Heating in a nitrogen atmosphere, keeping the material for 4 hours to carbonize the material, and obtaining a brown-black powder; stirring the resulting brown-black powder with 50 mL of 25% hydrofluoric acid solution for 4 hours, washing with deionized water and ethanol several times, and drying to obtain the obtained Ordered mesoporous nitrogen carbide materials.

[0037] b, the preparation of alkylated halide ion compounds

[0038] Take 0.5g of ordered mesoporous nitrogen carbide material, dissolve it in 100mL of DMF solution, then add 14g of methyl iodide, heat and reflux at 90°C for 5 hours, filter with suction, and wash the obtained solid with distilled water and acetone respective...

Embodiment 3

[0044] a. Synthesis of ordered mesoporous nitrogen carbide materials

[0045] Mix 2g of SBA-15, 12g of carbon tetrachloride, and 5.4g of ethylenediamine in a certain proportion, heat and reflux at 100°C for 3 hours, dry overnight, then place it in a quartz tube, and heat it under 500°C and 40ml / min of pure nitrogen Heating in the atmosphere, keeping the material for 4 hours to carbonize the material, and obtaining a brown-black powder; stirring the obtained brown-black powder with 100 mL of 25% hydrofluoric acid solution for 10 h, washing with deionized water and ethanol several times, and drying to obtain the described Ordered mesoporous nitrogen carbide materials.

[0046] b, the preparation of alkylated halide ion compounds

[0047] Take 0.5g of ordered mesoporous nitrogen carbide material, dissolve it in 100mL of DMF solution, then add 7g of methyl iodide, heat and reflux at 120°C for 10 hours, filter with suction, and wash the obtained solid with distilled water and aceton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com