Single-component polyurethane adhesive and preparation method thereof

A polyurethane adhesive, one-component technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of skinning, agglomeration, short storage period, etc., achieve strong catalytic effect, storage The effect of stability and breaking through the catalytic limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A one-component polyurethane adhesive consisting of an adhesive and a quick-drying agent:

[0043] The raw material composition and weight percentage of the adhesive are: 46% of polyether polyol PPG-2000, 51% of isocyanate Suprasec2020, and 3% of diol 1,4-butanediol.

[0044] Quick-drying agent composition and percentage by weight are: 20% catalyst dibutyltin dilaurate, 15% polyester polyol I-stickpolyolY, 5% silane coupling agent SilquestA-187, 10% silane coupling agent SilquestA-Link597, 50% solvent ethyl acetate.

[0045] In this embodiment, a quick-drying agent component of 2% by weight of the adhesive is added.

[0046] The preparation method of above-mentioned one-component polyurethane adhesive comprises the steps:

[0047](1) Preparation of adhesive: Accurately weigh each raw material according to the weight percentage, pour the isocyanate Suprasec2020 into the stirring tank, heat the stirring tank to 70-90°C, add polyether polyol PPG2000 and stir evenly, seal...

Embodiment 2

[0050] A one-component polyurethane adhesive consisting of an adhesive and a quick-drying agent:

[0051] The raw material composition and weight percentage of the adhesive are: 15% polyether polyol PPG-400, 7% polyester polyol I-stickpolyol160, 55% isocyanate Suprasec3056, 1% diol 1,4-butyl Diol, 13.7% solvent ethyl acetate, 8% solvent acetone, 0.3% catalyst I-stickcatalyst001.

[0052] Quick-drying agent composition and percentage by weight are: 18% catalyst dibutyltin dilaurate, 2% catalyst triethylenediamine, 15% polyester polyol I-stickpolyolY, 3% silane coupling agent SilquestA- 187. 5% silane coupling agent SilquestA-Link597, 50% solvent ethyl acetate, 7% solvent acetone.

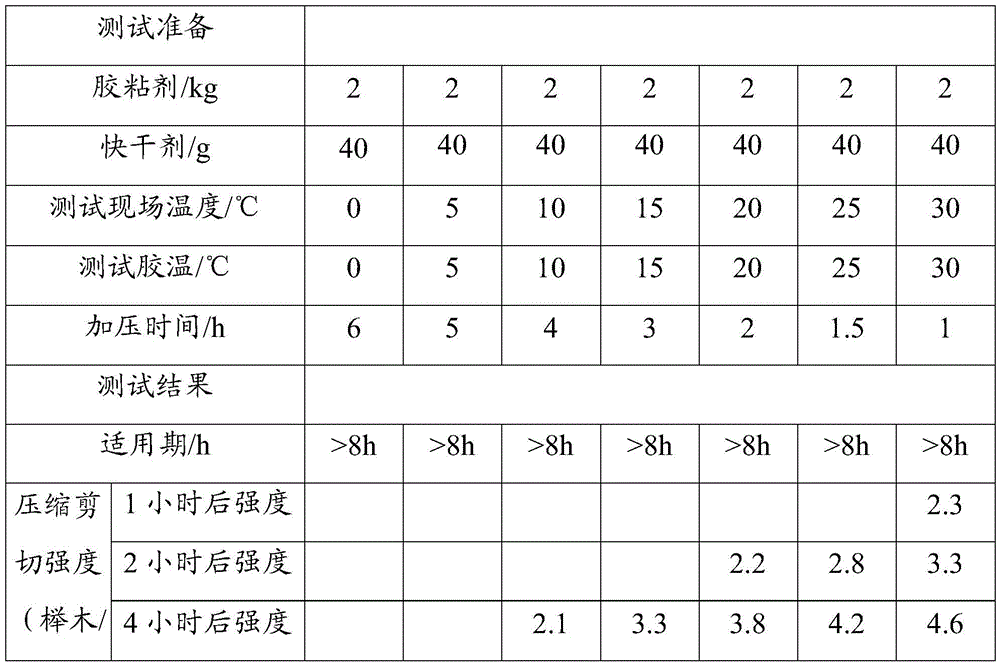

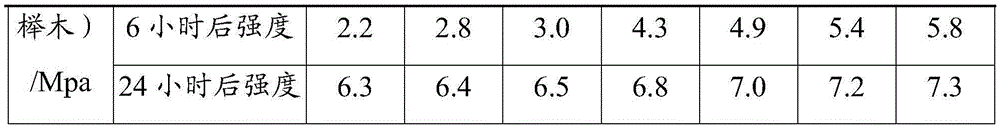

[0053] In this embodiment, different weights of quick-drying agent components are added with different temperatures, as shown in Table 2 below.

[0054] The preparation method of above-mentioned one-component polyurethane adhesive comprises the steps:

[0055] (1) Preparation of adhesive: Accurate...

Embodiment 3

[0058] A one-component polyurethane adhesive consisting of an adhesive and a quick-drying agent:

[0059] The raw material composition and weight percentage of the adhesive are: 30% polyester polyol I-stickpolyol160, 60% isocyanate Suprasec3056, and 10% solvent ethyl acetate.

[0060] The quick-drying agent composition and percentage by weight are: 20% catalyst dibutyltin dilaurate, 1% catalyst triethylenediamine, 15% polyester polyol I-stickpolyolY, 3% silane coupling agent SilquestA- 187. 5% silane coupling agent SilquestA-Link597, 10% plasticizer trioctyl citrate, 46% solvent ethyl acetate.

[0061] In this embodiment, a quick-drying agent component of 5% by weight of the adhesive is added.

[0062] The preparation method of above-mentioned one-component polyurethane adhesive comprises the steps:

[0063] (1) Preparation of adhesive: Accurately weigh each raw material according to the weight percentage, pour the isocyanate Suprasec3056 into the stirring tank, heat the sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com