Method for separating heavy metals in trichlorosilane

A technology of trichlorosilane and heavy metals, applied in the direction of non-metallic elements, chemical instruments and methods, halosilane, etc., can solve the problems of high safety risk, difficult process, amplification, etc., and achieve high removal efficiency and efficient adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

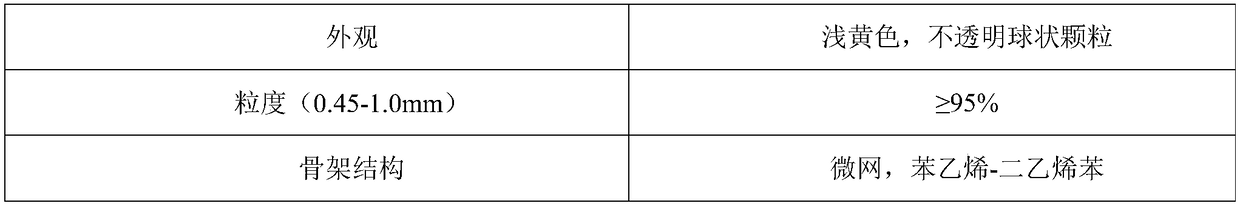

Method used

Image

Examples

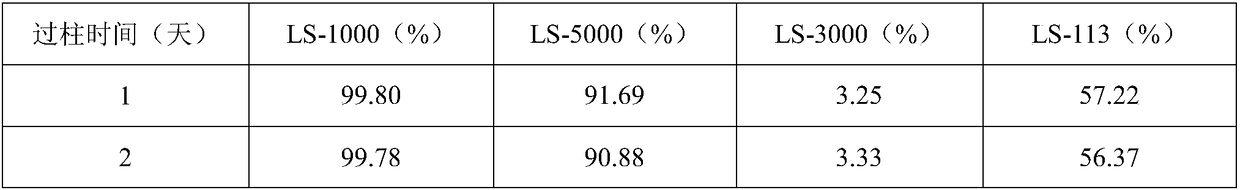

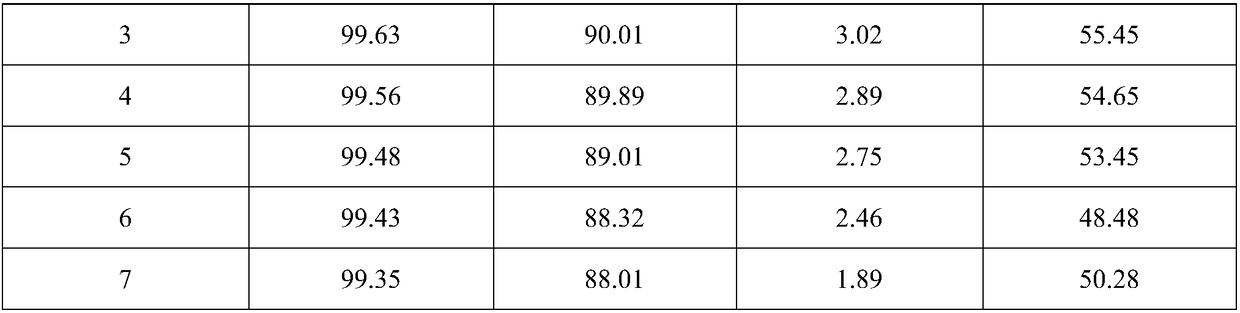

example 1

[0055] The separation method of heavy metals in trichlorosilane provided by the present invention has been technically demonstrated in a company in the electronic grade polysilicon industry and has been applied industrially. The factory area used in the test produces trichlorosilane. The ion removal rate is as high as 99.8%, and the treatment effect exceeds the expected effect in the factory. At present, a set of 50 tons / hour industrial equipment is in stable operation, and the effect of adsorption and separation of heavy metal ions is stable, safe and reliable.

example 2

[0057] The separation method of heavy metals in trichlorosilane has been technically demonstrated in a company in the solar-grade polysilicon industry and has been applied industrially. The factory area used in the test produces trichlorosilane. The removal rate of heavy metals reaches 99.5%, and the treatment effect meets the technical requirements of the factory area. At present, a set of 100 tons / hour industrial equipment has been put into operation in September 2017. The effect of adsorption and separation of heavy metal ions is stable and brings considerable economic benefits to the factory area. Labor intensity of workers. This method for separation of heavy metal ions in trichlorosilane has good effect, the system occupies a small area, is simple to operate, reliable in operation, convenient in maintenance, operates continuously for 24 hours, and greatly improves production efficiency. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com