Anti-pollution modification method of polypropylene hollow fiber membrane module

A fiber membrane and polypropylene technology, applied in the field of anti-pollution modification of polypropylene hollow fiber membrane modules, can solve the problems of difficult control of treatment effect and low modification efficiency, and achieve improved anti-pollution performance, increased efficiency, and easy construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] 1) Select a polypropylene hollow fiber membrane with an average inner diameter of 1.2 mm, an outer diameter of 1.8 mm, and a membrane pore size of 0.1 μm, soak it in ethanol for 12 hours, and then wash it with deionized water for 3 times to remove the hollow fibers adsorbed on polypropylene. Impurities on the surface of the fiber membrane are then placed in an oven at 60°C, dried and packaged into a polypropylene hollow fiber membrane module, the module length is 22cm, and the number of filled membrane filaments is 16;

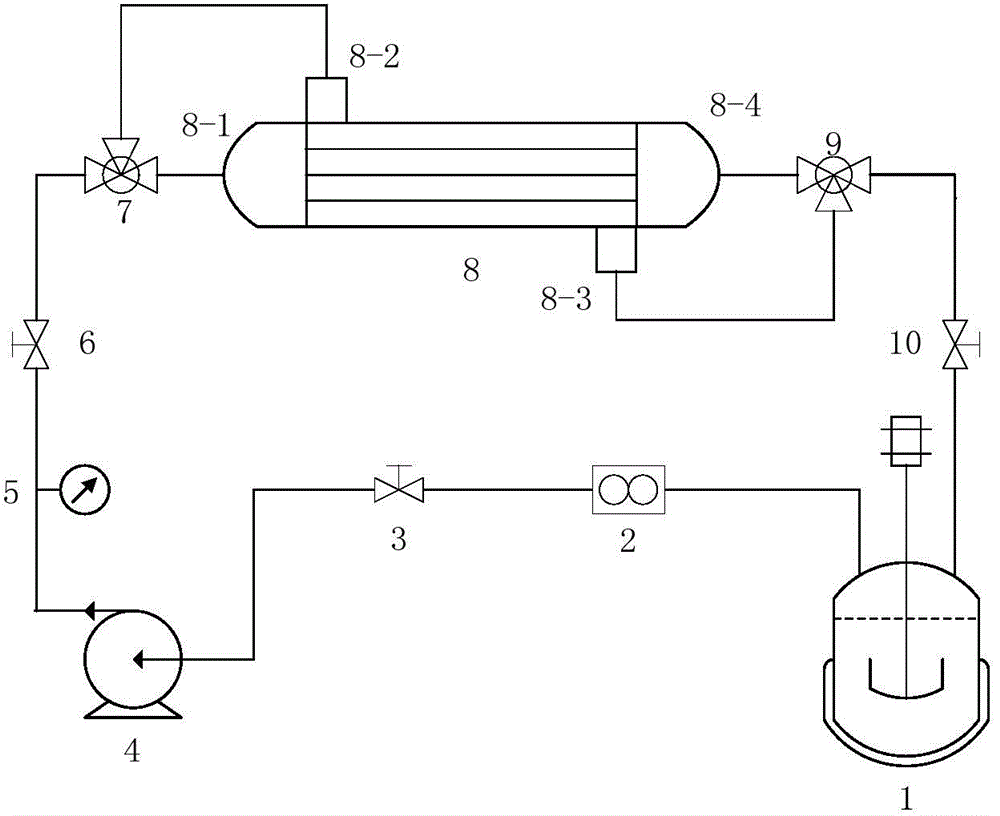

[0118] 2) Connect the packaged polypropylene hollow fiber membrane module 8 to the device used for anti-pollution modification, open the first valve 3 and the second valve 6, and put 50% of the mass percentage of pentadiene in the liquid storage tank 1 The aldehyde cross-linking agent solution is delivered to the polypropylene hollow fiber membrane module 8 with the liquid delivery pump 4 under continuous stirring, and the flow meter 2 and the pressure g...

Embodiment 2

[0124] 1) Select a polypropylene hollow fiber microporous membrane with an average inner diameter of 1.4 mm, an outer diameter of 2.1. Impurities on the surface of the membrane are then placed in an oven at 50°C, dried and packaged into a polypropylene hollow fiber membrane module with a length of 20cm and 15 membrane filaments;

[0125] 2) Connect the packaged propylene hollow fiber membrane module 8 to the device used for anti-pollution modification, open the first valve 3 and the second valve 6, and fill the liquid storage tank 1 with 10% glutaraldehyde The cross-linking agent solution is delivered to the polypropylene hollow fiber membrane module 8 with the liquid delivery pump 4 under continuous stirring, and the flow meter 2 and the pressure gauge 5 are adjusted to control the flow rate of the cross-linking agent solution to be 1ml / min. 7 and confluence valve 9, control the cross-linking agent solution to enter from the axial liquid inlet hole 8-1 of the membrane module,...

Embodiment 3

[0131] 1) Select a polypropylene hollow fiber membrane with an average inner diameter of 1.5mm, an outer diameter of 2.3mm, and a membrane pore diameter of 0.2μm, soak it in ethanol for 8 hours, and then wash it 4 times with deionized water to remove the particles adsorbed on the surface of the membrane. Impurities, then placed in an oven at 80°C, dried and packaged into a polypropylene hollow fiber membrane module, the module length is 23cm, and the number of filled membrane filaments is 17;

[0132] 2) Connect the packaged polypropylene hollow fiber membrane module 8 to the device used for anti-pollution modification, open the first valve 3 and the second valve 6, and put 40% ethylene glycol in the liquid storage tank 1 The aldehyde cross-linking agent solution is delivered to the polypropylene hollow fiber membrane module 8 with the liquid delivery pump 4 under continuous stirring, and the flow meter 2 and the pressure gauge 5 are adjusted to control the flow rate of the cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com