Sandwich structure for enhancing luminous intensity of photoluminescence of luminous film and preparation method of sandwich structure

A luminescent thin film and photoluminescent technology, which is applied in the direction of luminescent materials, chemical instruments and methods, thin material processing, etc., can solve the problems of reducing the fluorescence enhancement effect, easy to be oxidized, and long preparation time, so as to expand the application range and enhance The effect of luminous intensity and short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

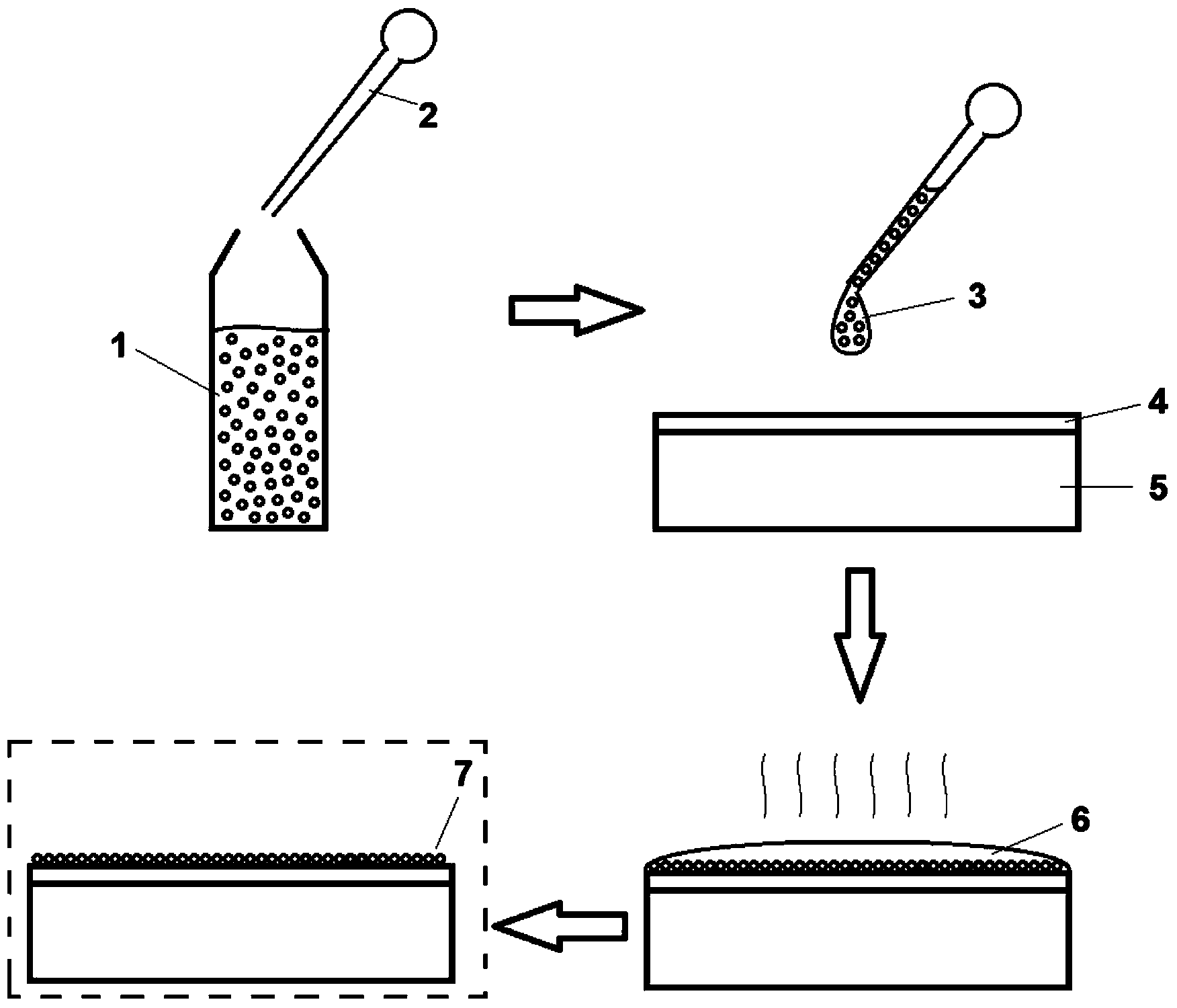

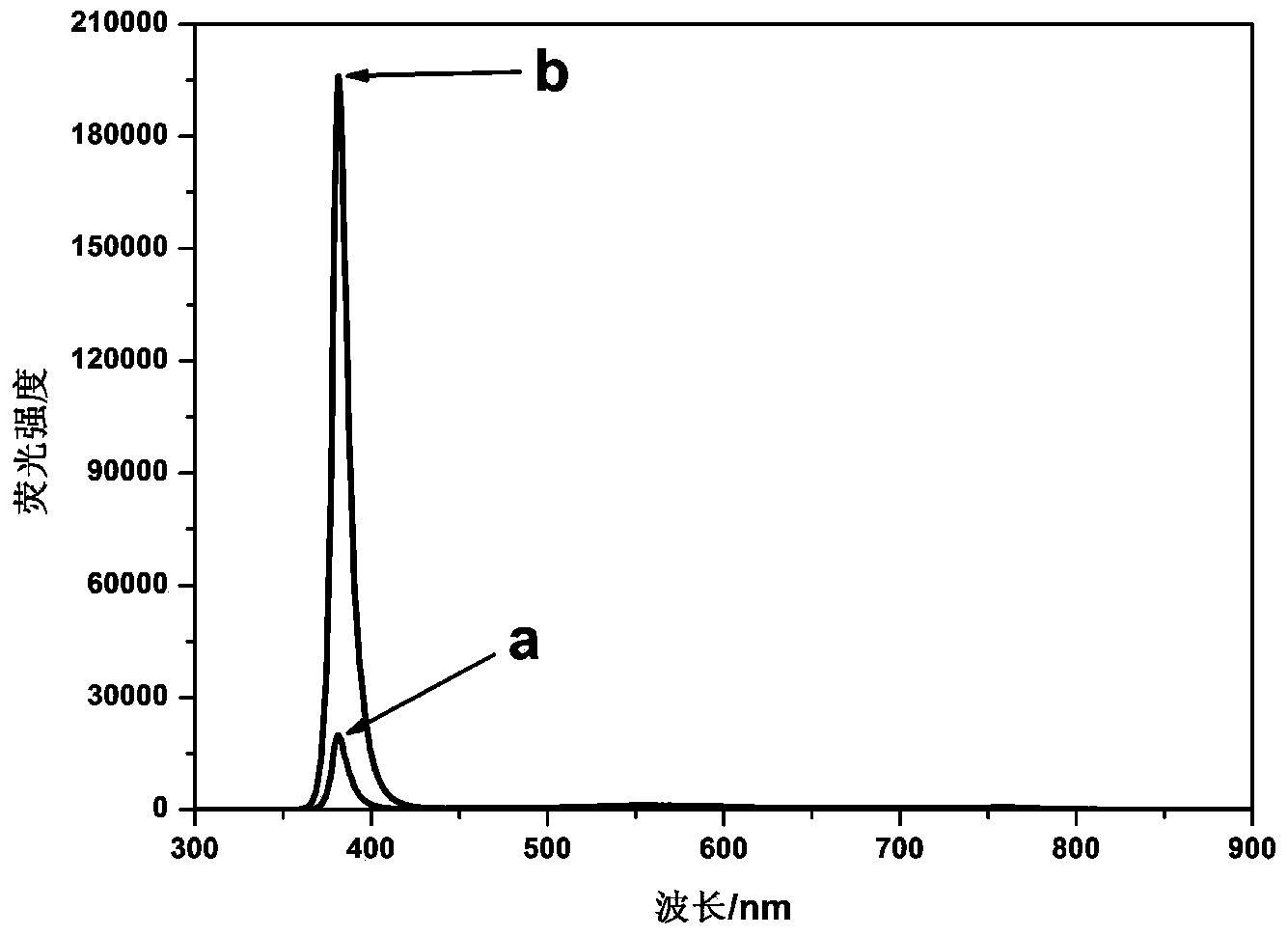

[0037] Silicon dioxide (SiO 2 ) transparent dielectric pellets mixed with isopropanol to form as figure 1 The indicated bead suspension, the bead concentration is about 1×10 5 µL -1 ;use figure 1 The dropper shown sucks the suspension of small balls, drops it on the surface of zinc oxide (ZnO) film grown on silicon carbide (SiC) single crystal substrate, and infiltrates the surface of zinc oxide film; at room temperature, when the suspension is in After natural evaporation of isopropanol, the following figure 1 The sandwich structure of silicon carbide single crystal substrate-zinc oxide film-single-layer densely packed silicon dioxide transparent dielectric sphere array is shown; as figure 2 As shown, using 325nm ultraviolet laser to excite the film, the obtained 380nm wavelength fluorescence intensity b is 11 times of the fluorescence intensity a of the non-bead dense film.

Embodiment 2

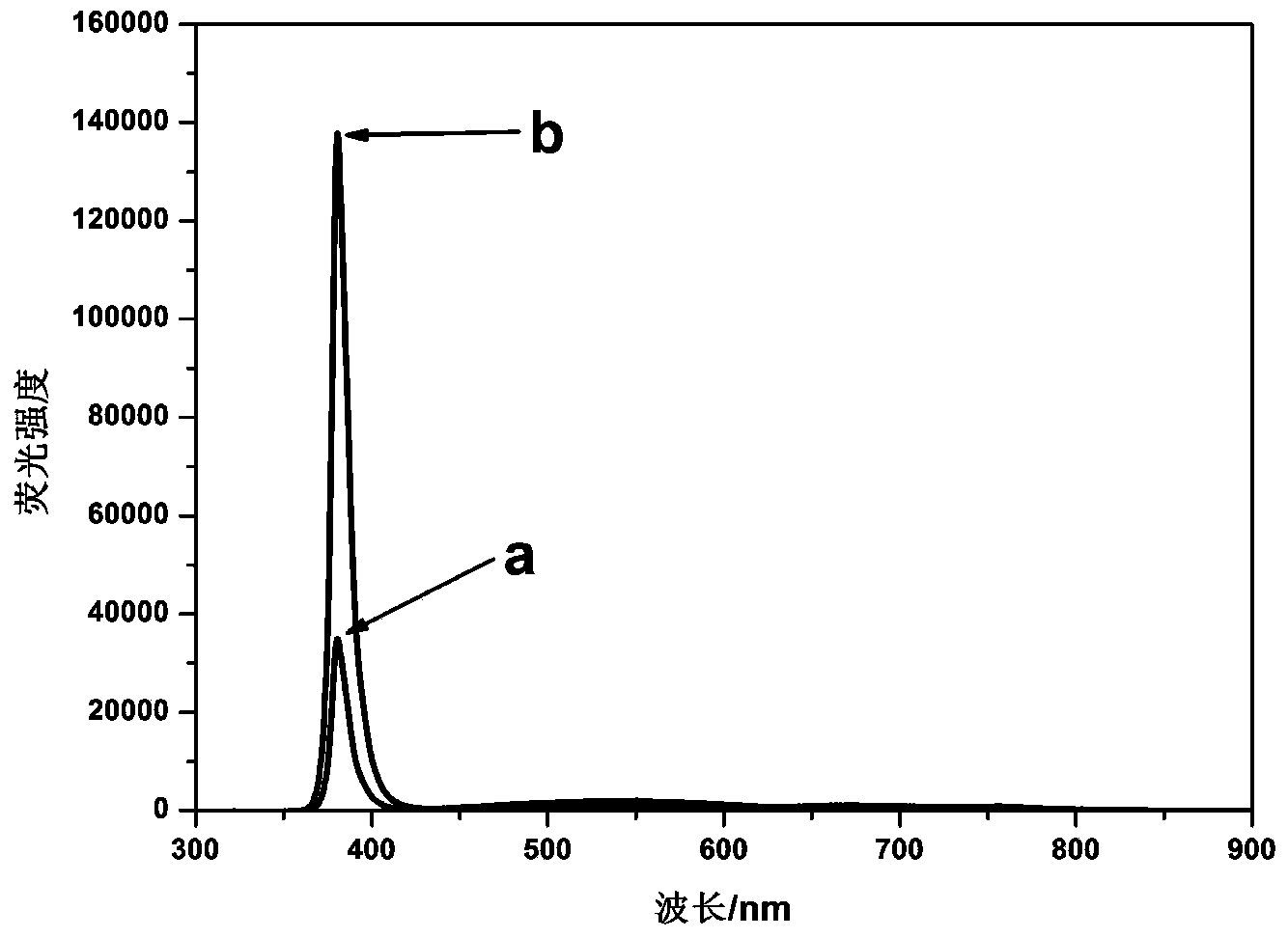

[0039] Silicon dioxide (SiO 2 ) Transparent dielectric pellets are mixed with water to form as figure 1 The indicated bead suspension, the bead concentration is about 4×10 4 µL -1 ;use figure 1 The dropper shown sucks the pellet suspension, drops it on the surface of the zinc oxide (ZnO) film grown on the metal titanium (Ti) substrate, and infiltrates the surface of the zinc oxide film; at room temperature, when the water in the suspension After natural evaporation, get as figure 1 The sandwich structure of metal titanium substrate-zinc oxide film-single-layer densely packed silicon dioxide transparent dielectric sphere array is shown; as image 3 As shown, using 325nm ultraviolet laser to excite the film, the obtained 380nm wavelength fluorescence intensity b is 3 times of the fluorescence intensity a of the densely packed film without small balls.

Embodiment 3

[0041] Silicon dioxide (SiO 2 ) Transparent dielectric pellets are mixed with ethanol to form as figure 1 The indicated bead suspension, the bead concentration is about 8×10 4 µL -1 ;use figure 1 The dropper shown sucks the bead suspension, drops it on the surface of the zinc oxide (ZnO) film grown on the graphene substrate, and infiltrates the surface of the zinc oxide film. At room temperature, when the ethanol in the suspension evaporates naturally, the following figure 1 The sandwich structure of graphene substrate-ZnO thin film-monolayer close-packed silicon dioxide transparent dielectric sphere array is shown. Such as Figure 4 As shown, using 325nm ultraviolet laser to excite the film, the obtained 380nm wavelength fluorescence intensity b is 3 times of the fluorescence intensity a of the densely packed film without small balls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com