Device for improving sulfur recovery rate and its recovery method

A recovery device and recovery rate technology, applied in chemical instruments and methods, sulfur compounds, sulfur preparation/purification, etc., can solve the complex process, high operating costs and energy consumption, and tail gas emission indicators that cannot meet environmental protection in environmentally sensitive areas. requirements and other issues, to achieve the effect of simple process, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

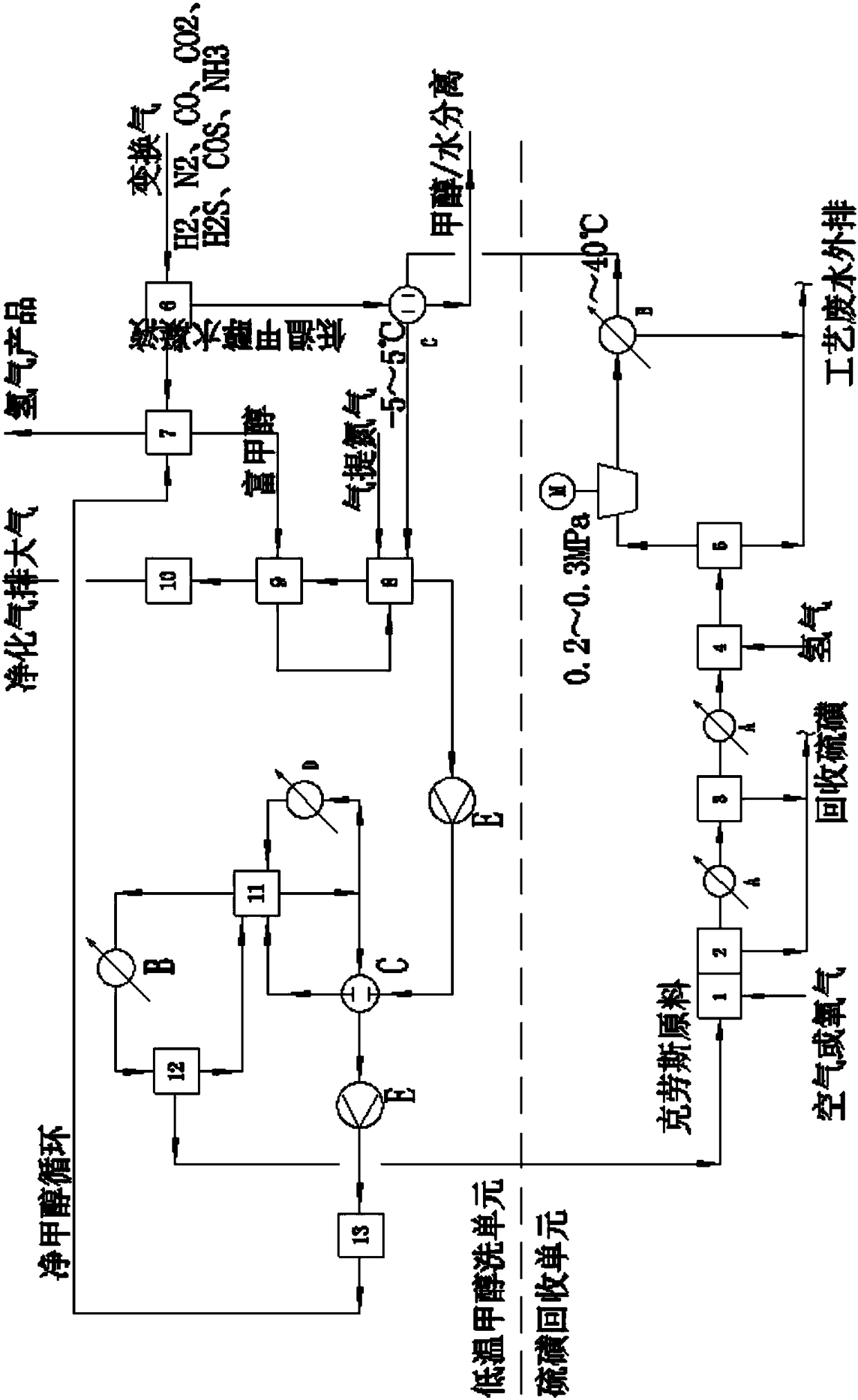

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Firstly, the device for improving the recovery rate of sulfur will be introduced. This device belongs to the recovery device. The device for improving the sulfur recovery rate includes a tail gas recovery device in the sulfur production process, a shift gas recovery device and a circulation system. The present invention installs the tail gas recovery device and the shift gas recovery device in the sulfur production process together, and the remaining products in the recovery process pass through The recycling system is used repeatedly, which not only saves costs, but also improves the efficiency of recycling.

[0019] The recovery device in the sulfur production process includes Claus reactor 1, Claus converter, Claus tail gas hydrogenation reduction system, and cooling system. Claus reactor 1 and Claus converter are connected together to have a recovery syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com