Gradient MCrAlX coating single-target electric arc ion plating one-step preparation method

A technology of arc ion plating and arc ion, which is applied in the field of coating, can solve the problems of poor controllability, low efficiency, cumbersome preparation process of gradient MCrAlX coating, etc., and achieve low cost, compact structure, process stability and high preparation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

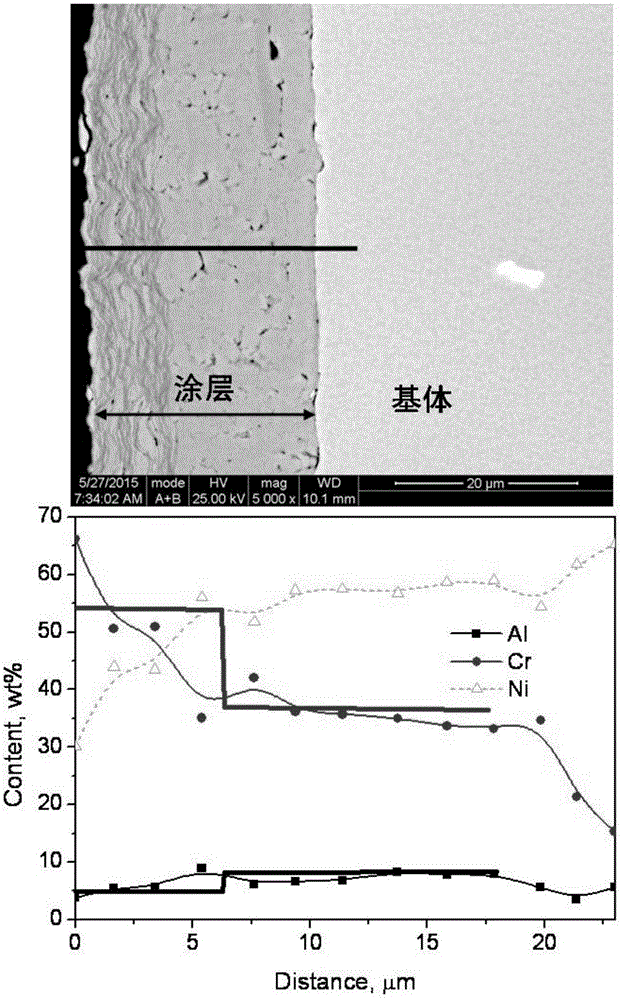

[0020] This embodiment illustrates the preparation method of a double-layer gradient NiCrAlY coating with a chromium-rich inner layer and a low chromium and high aluminum layer. First, NiCrAlY, Ni-27Cr-11Al-0.5Y, mass percent wt%, the target is installed in the cathode water-cooled target sleeve, the substrate test piece is hung in front of the target, the vacuum chamber door is closed, and the air is pumped; the vacuum degree of the coating chamber reaches 5 ×10 -3 When Pa or higher, the cathodic arc is ignited; first, a pulsed high negative bias is applied to the substrate for coating, with an amplitude of 400-800V and a duty cycle of 10%-80%. When the bias voltage amplitude is 400-600V, the duty cycle should be as large as 30%-80%, and when the bias voltage amplitude is 600-800V, the duty cycle should be as small as 10%-30%. The selection of the bias voltage amplitude is based on the enrichment degree of chromium in the desired deposited coating. The higher the bias voltag...

Embodiment 2

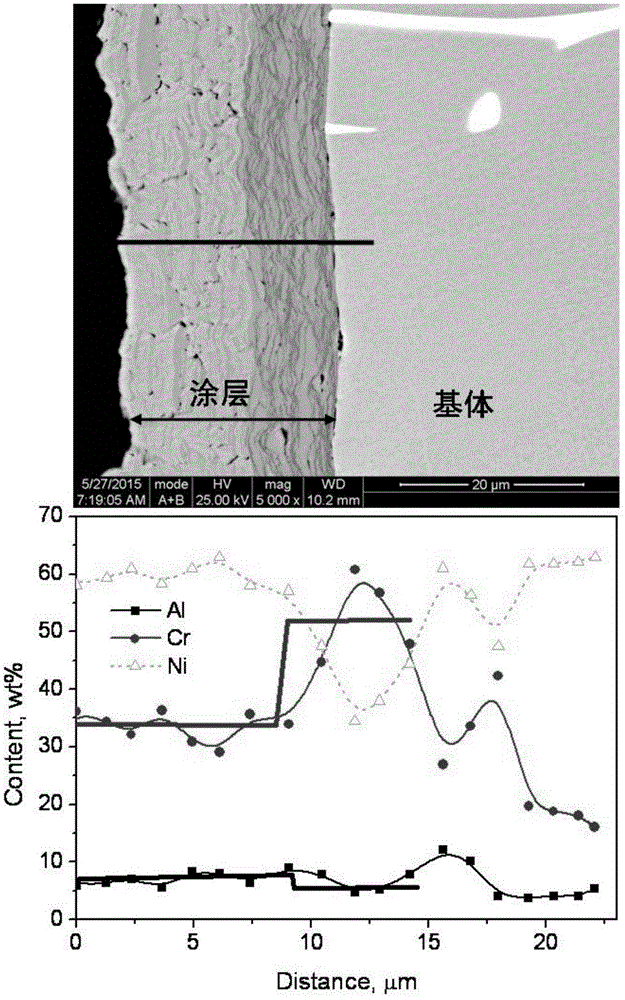

[0022] This example illustrates the preparation method of a double-layer gradient NiCrAlY coating with low chromium on the surface and high aluminum on the inner layer rich in chromium. First, NiCrAlY, Ni-27Cr-11Al-0.5Y, mass percent wt%, the target is installed in the cathode water-cooled target sleeve, the substrate test piece is hung in front of the target, the vacuum chamber door is closed, and the air is pumped; the vacuum degree of the coating chamber reaches 5 ×10 -3 When Pa or higher, the cathodic arc is ignited; in this example, the pulse bias voltage of the bottom layer is -450V, and the pulse bias voltage of the surface layer is -50V. The arc current is 200A, the pulse negative bias frequency is 40kHz, and the duty cycle is 40%. The coating time depends on the thickness of the required coating. In this example, the arc source is turned off after 2 hours for each layer of coating. Thus, a double-layer gradient NiCrAlY coating with low chromium on the surface and hi...

Embodiment 3

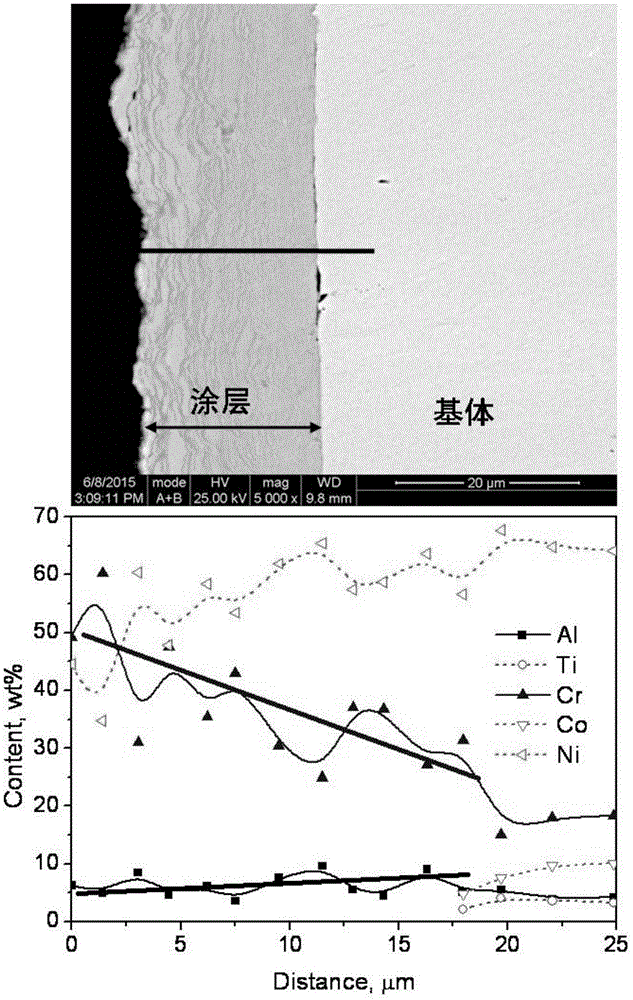

[0024] This embodiment illustrates the preparation method of the gradient NiCrAlY coating whose chromium content gradually decreases and the aluminum content gradually increases from the surface to the interior. Also at 5×10 -3 When Pa or higher, the cathodic arc is ignited; the substrate is coated with a pulsed negative bias voltage whose amplitude increases continuously or stepwise with time. The deposition is carried out in the form of pressure amplitude. The current is the same as the previous example. The pulse negative bias voltage applied to the substrate has a frequency of 20 kHz and a duty cycle of 40%. Thus, a gradient NiCrAlY coating with gradually decreasing chromium content and increasing aluminum content from the surface to the interior is obtained. The scanning electron microscope photos and energy spectrum composition analysis of the coating cross section are as follows image 3 shown. Since the aluminum content of the target is relatively low, the gradient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com