Efficient boiling heat transfer copper material and preparation method thereof

A boiling heat transfer and copper technology, applied in nanotechnology and other directions, can solve the problems of uncontrollable processing quality of nanowires, uncontrollable formation process, sharp increase in processing cost, etc., and achieve excellent boiling heat transfer performance and high critical heat flux density. , the effect of low superheat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

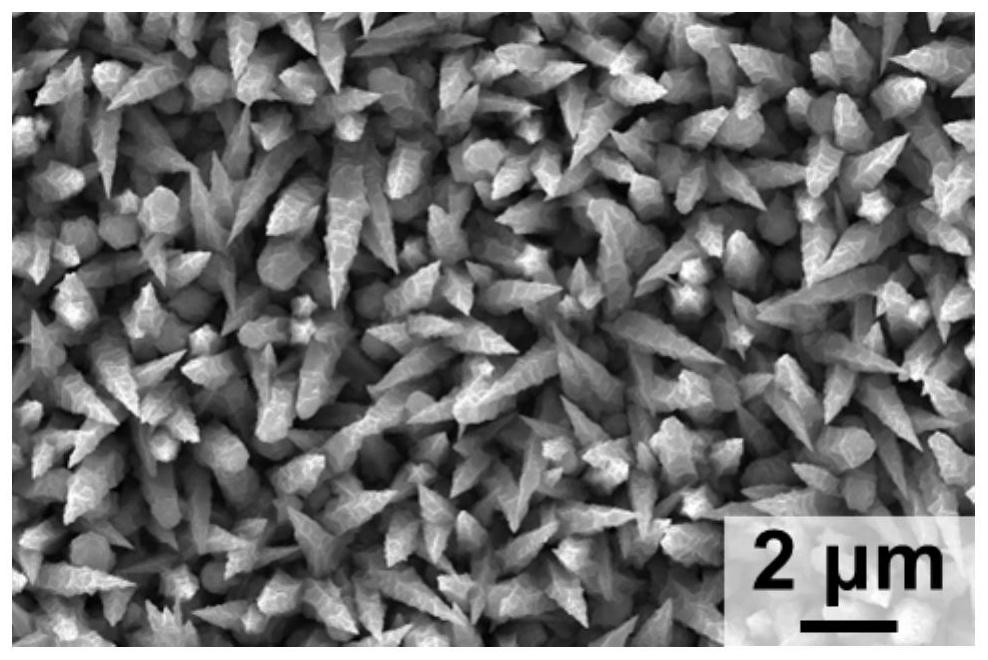

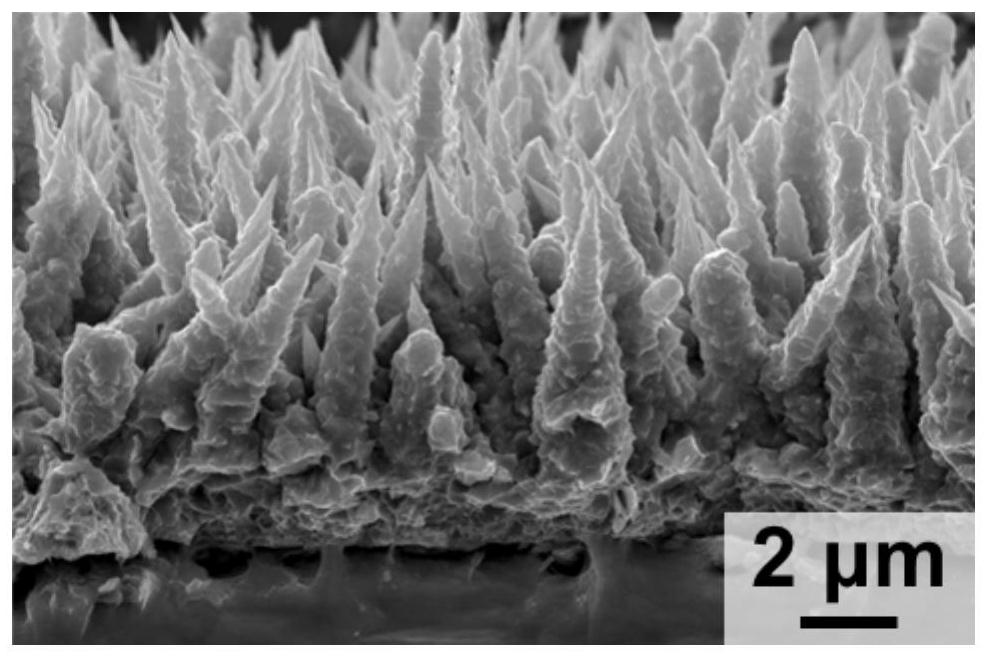

[0027] Another aspect of the embodiments of the present invention provides a method for preparing a high-efficiency boiling heat transfer copper material, which includes: combining a substrate as a working electrode with a counter electrode and a weakly alkaline copper salt electrolyte to form an electrochemical working system , and apply a reduction current between the working electrode and the counter electrode, and form a porous copper film on the surface of the substrate through an electrodeposition reaction. The porous copper film includes several copper nano cones, and the copper nano cones distributed between the plurality of copper nano cones Irregular open microcavities are interconnected to form a porous microcavity structure;

[0028] In addition, the copper nanocone is in the shape of a needle cone, with an average height of 3-8 μm, a bottom diameter of 500-2200 nm, and a tip diameter of 0-50 nm.

[0029] Further, the distribution density of the copper nano cones i...

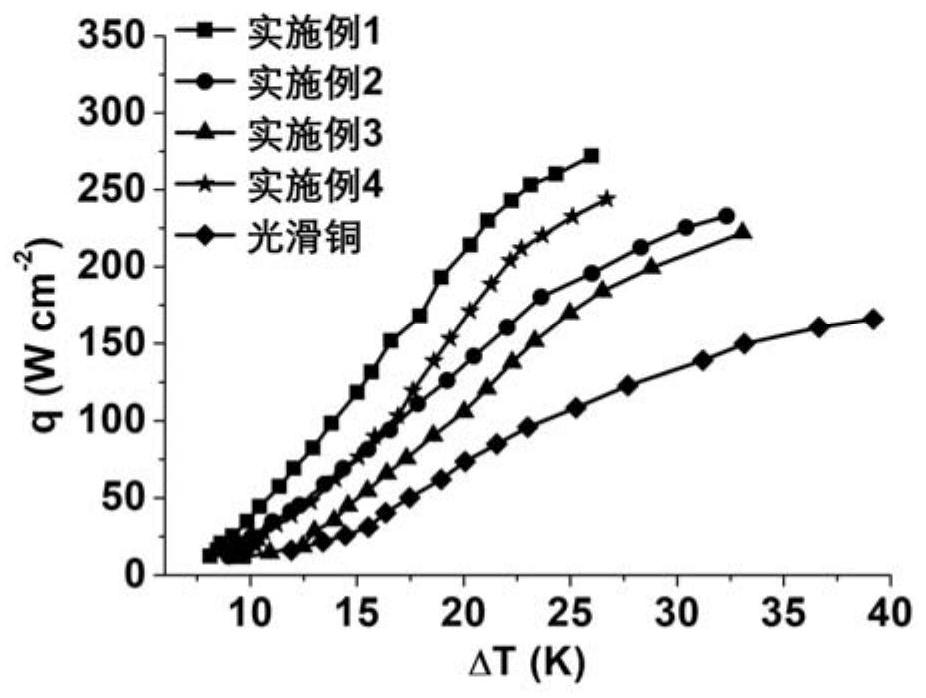

Embodiment 1

[0047] This embodiment relates to a nano-cone structure high-efficiency boiling heat transfer copper material prepared by electrochemical deposition, which is used to enhance boiling heat transfer. Specific steps are as follows:

[0048] (1) Polish the surface of the copper test piece, rinse it with ultrapure water, and dry it with high-purity nitrogen. This step is to remove the surface oxide layer.

[0049] (2) The copper test piece processed in step (1) is used as the working electrode, placed in the weakly alkaline copper salt electrolyte solution, the platinum electrode is used as the counter electrode, and the silver / silver chloride is used as the reference electrode. The working electrodes are connected by wires, and a loop is formed between the counter electrode and the reference electrode. The distance between the counter electrode and the working electrode was controlled to be 60mm, and the constant voltage electrodeposition reaction was carried out in a constant t...

Embodiment 2

[0053] This embodiment relates to a nano-cone structure high-efficiency boiling heat transfer copper material prepared by electrochemical deposition, which is used to enhance boiling heat transfer. Specific steps are as follows:

[0054] (1) Polish the surface of the copper test piece, rinse it with ultrapure water, and dry it with high-purity nitrogen. This step is to remove the surface oxide layer.

[0055] (2) The copper test piece processed in step (1) is used as the working electrode, placed in the weakly alkaline copper salt electrolyte solution, the platinum electrode is used as the counter electrode, and the silver / silver chloride is used as the reference electrode. The working electrodes are connected by wires, and a loop is formed between the counter electrode and the reference electrode. The distance between the counter electrode and the working electrode was controlled to be 40mm, and the constant voltage electrodeposition reaction was carried out in a constant t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com