Preparation method of transparent dielectric microsphere flexible film with enhanced Raman scattering light intensity

A technology of enhanced Raman scattering and flexible thin films, applied in the field of spectral detection, can solve the problems of array deposition effects, unfavorable application of direct deposition microsphere preparation methods, difficult to clean microspheres, etc., achieving short preparation time, low price, The effect of simple removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

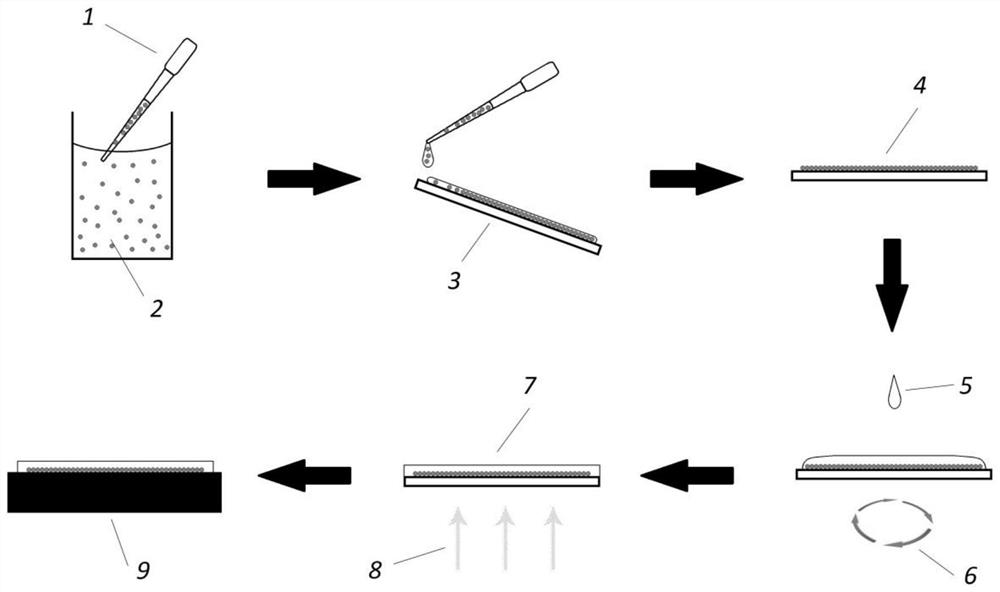

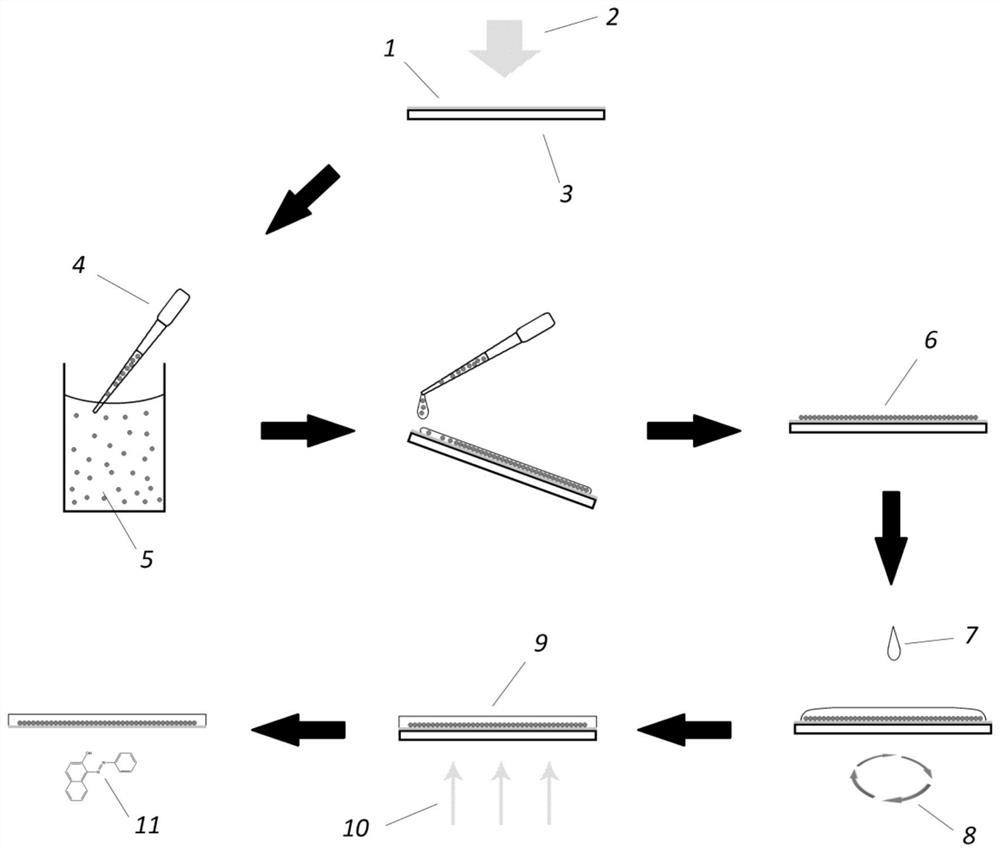

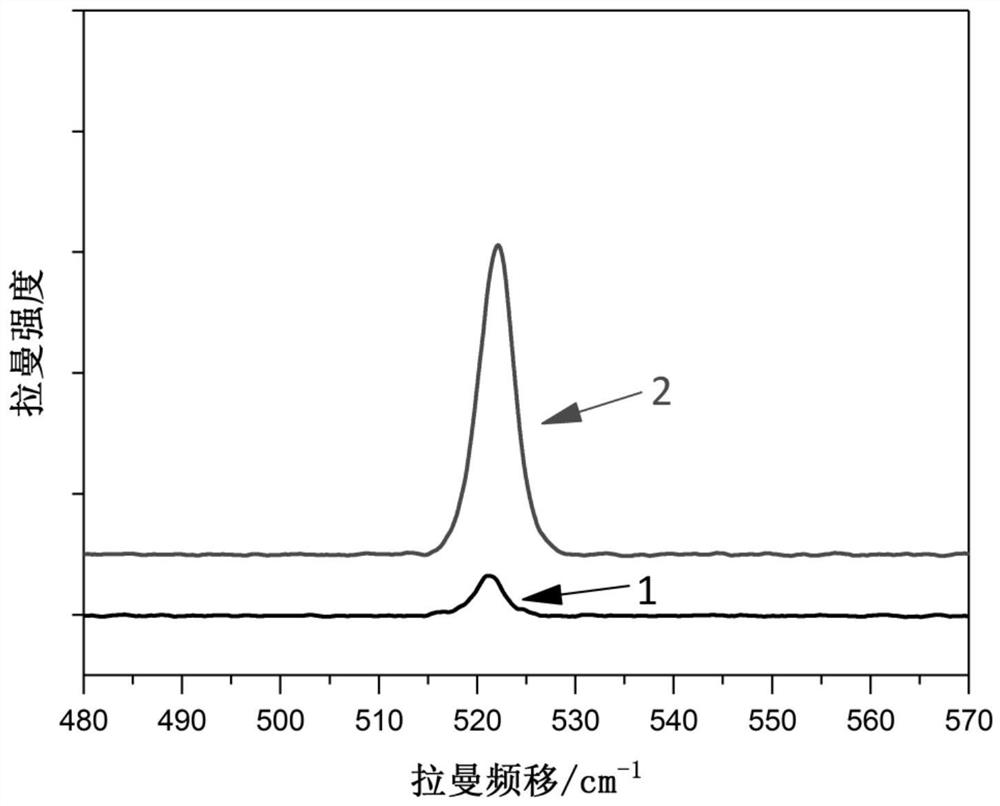

[0049] Mix high-refractive-index glass microspheres with a diameter of 22 μm and water to form a microsphere suspension, and the concentration of the microspheres is about 5×10 3 pcs.μL -1 . Use a dropper to absorb the microsphere suspension, and drop it on the glass substrate with an inclination angle of 20 degrees. At room temperature, when the water in the suspension evaporates naturally, a monolayer array of 22 μm high refractive index glass microspheres densely covered on the surface is obtained. Mix and fully stir the main agent and curing agent of PDMS at a mass ratio of 10:1, and drop-coat it on the microsphere array, then use a homogenizer to rotate at 950 rpm for 60s, and then place it on the heating The platform was heated up to 100°C and kept for 10 minutes until the PDMS was completely solidified and cooled to room temperature naturally. Finally, use tweezers to peel off the film from the glass substrate, cut out an appropriate area of the film and attach it ...

Embodiment 2

[0051] Mix high-refractive index glass microspheres with a diameter of 39.5 μm and ethanol to form a microsphere suspension, and the concentration of the microspheres is about 1×10 3 pcs.μL -1 . Use a dropper to absorb the microsphere suspension, and drop it on the glass substrate with an inclination angle of 30 degrees. At room temperature, when the ethanol in the suspension evaporates naturally, a monolayer array of 39.5 μm high refractive index glass microspheres densely covered on the surface is obtained. Mix and fully stir the main agent and curing agent of PDMS at a mass ratio of 10:1, and drop-coat it on the microsphere array, and then use a homogenizer to rotate at 1000 rpm for 40s, and then place it on the heating The platform was heated up to 100°C, kept for 5 minutes until the PDMS was completely solidified, and then cooled to room temperature naturally. Finally, use tweezers to peel off the film from the glass substrate, cut out an appropriate area of the film...

Embodiment 3

[0053] Mix high-refractive-index glass microspheres with a diameter of 55 μm and isopropanol to form a microsphere suspension, and the concentration of the microspheres is about 5×10 2 pcs.μL -1 . Use a dropper to absorb the microsphere suspension, and drop it on the glass substrate with an inclination angle of 30 degrees. At room temperature, when the isopropanol in the suspension evaporates naturally, a monolayer array of 55 μm high refractive index glass microspheres densely covered on the surface is obtained. Mix and fully stir the main agent and curing agent of PDMS at a mass ratio of 10:1, and drop-coat it on the microsphere array, and then use a homogenizer to rotate at 600 rpm for 60s, and then place it on the heating The temperature in the furnace was raised to 100°C, and the temperature was kept for 20 minutes until the PDMS was completely solidified, and then naturally cooled to room temperature. Finally, use tweezers to peel off the film from the glass substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com