Multi-dimensional air staged low NOx combustion system and layout method

An air classification and combustion system technology, applied in the field of boilers, can solve the problems of boiler water wall slagging, boiler combustion deterioration, boiler tangential reversal and other problems, to strengthen mixing, reduce carbon content in bottom slag, and reduce NOx emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

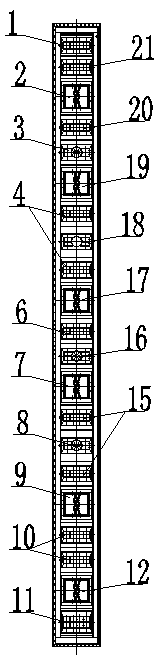

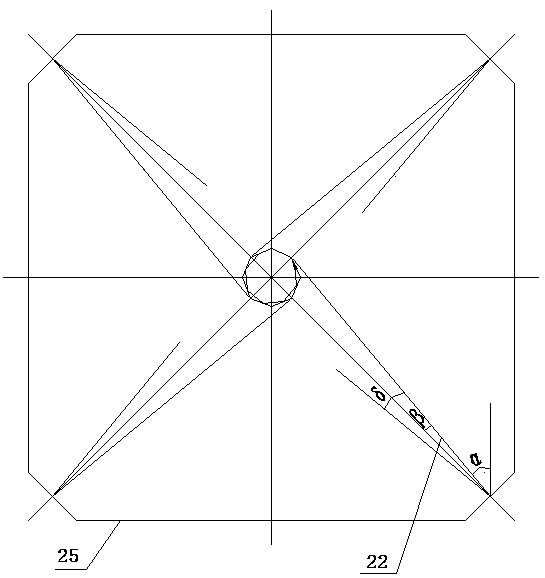

[0023] A multi-dimensional air staged low NOx combustion system, which consists of: a main burner and a two-stage burn-off air burner, the main burners are respectively arranged at the four corners of the boiler furnace 25, and the center of the main burner The axis 22 forms an included angle with the boiler furnace water wall α,α 40-43°, the main burner is arranged with a group of secondary air nozzles and primary air nozzles arranged at intervals to form a small imaginary tangent circle, which can effectively avoid slagging and high temperature corrosion on the water wall.

Embodiment 2

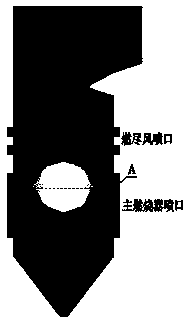

[0025] According to the multidimensional air staged low NOx combustion system described in Embodiment 1, the secondary air nozzles include a set of auxiliary secondary air nozzles, a set of oil secondary air nozzles and OFA air nozzles 1, and a set of auxiliary air nozzles 1 The secondary air nozzles are AA layer auxiliary secondary air nozzle 11, AB layer auxiliary secondary air nozzle 10, BC layer auxiliary secondary air nozzle 15, CD layer auxiliary secondary air nozzle 6, DE layer auxiliary secondary air nozzle 4 , EF layer auxiliary secondary air nozzle 20 and FF layer auxiliary air secondary air nozzle 21, one group of oil secondary air nozzles are respectively BC layer oil secondary air nozzle 8, CD layer oil secondary air nozzle 16, DE layer oil secondary air nozzle 18 and EF layer oil secondary air nozzle 3, the OFA air forms a tangential circle in the boiler in the opposite direction to the auxiliary air secondary air, which is conducive to strengthening the mixing of...

Embodiment 3

[0027] According to the multi-dimensional air staged low NOx combustion system described in embodiment 1 or 2, the primary air nozzles include A layer primary air nozzles 12, B layer primary air nozzles 9, two lower layer primary air nozzles, C layer primary air nozzles 7 1, D layer primary air nozzle 17 two middle layer primary air nozzles and E layer primary air nozzle 19, F layer primary air nozzle 2 two upper layer primary air nozzles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com