Split hot air type low-nitrogen gas burner

A gas burner, split technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problem of high flame temperature, achieve the effect of reducing NOX emission, reducing NOX generation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

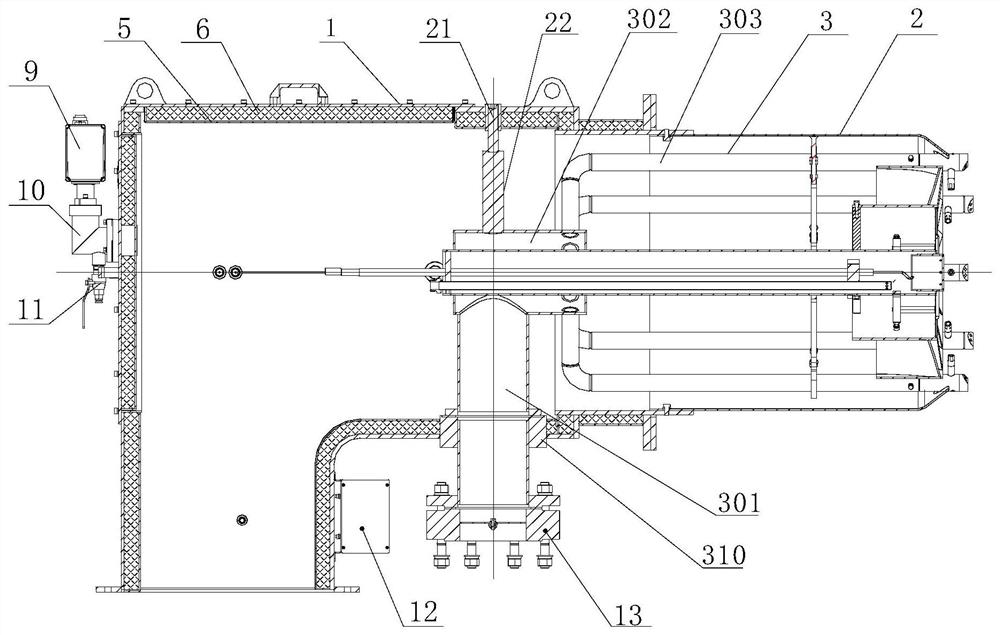

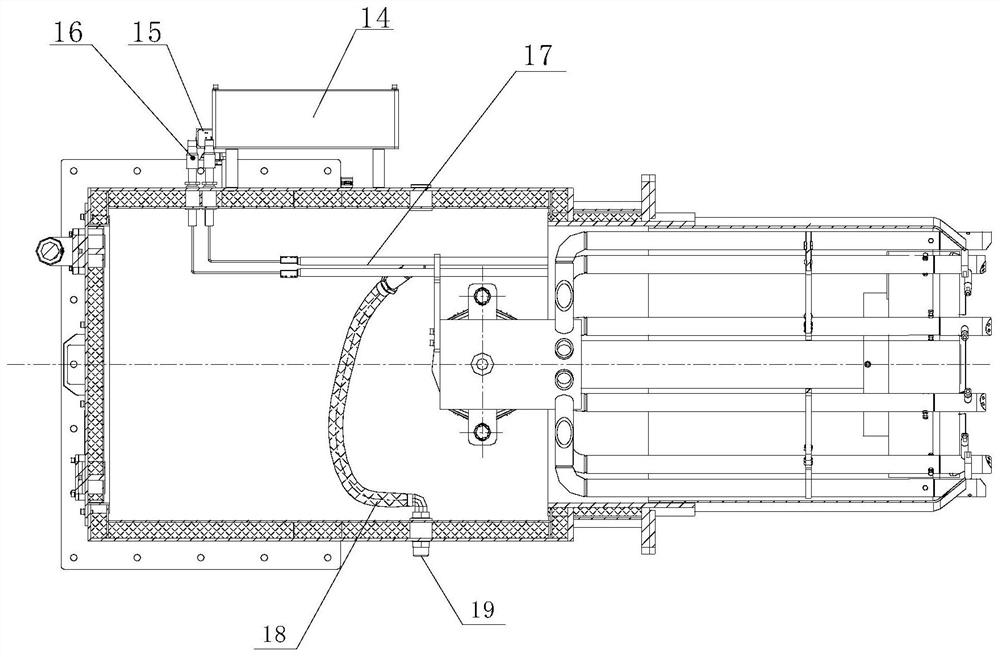

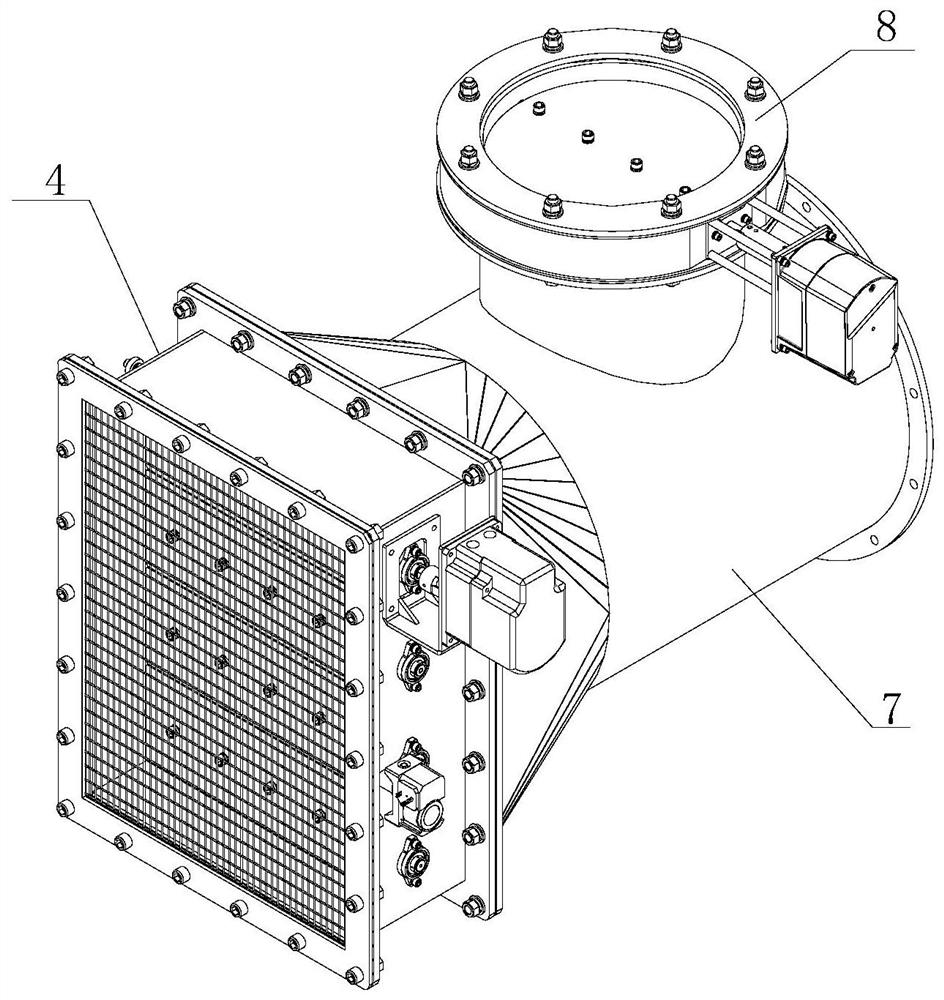

[0054] Such as Figure 1-2 As shown, a split hot air type low-nitrogen gas burner includes a burner housing 1 , a flame tube 2 , a central gas pipe assembly 3 , an ignition gun assembly 17 and a damper adjustment mechanism assembly 4 . A thermal insulation structure is provided on the inner wall of the burner housing 1, and the thermal insulation structure includes a thermal insulation board 5 and a thermal insulation cotton 6 with a thickness of 28-32mm, generally preferably 30mm thermal insulation cotton, and a thermal insulation cotton 6 is pasted on the inner wall of the burner housing 1, and the thermal insulation board 5 is fixed on the outer surface of the thermal insulation cotton 6, which plays a role of thermal insulation in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com