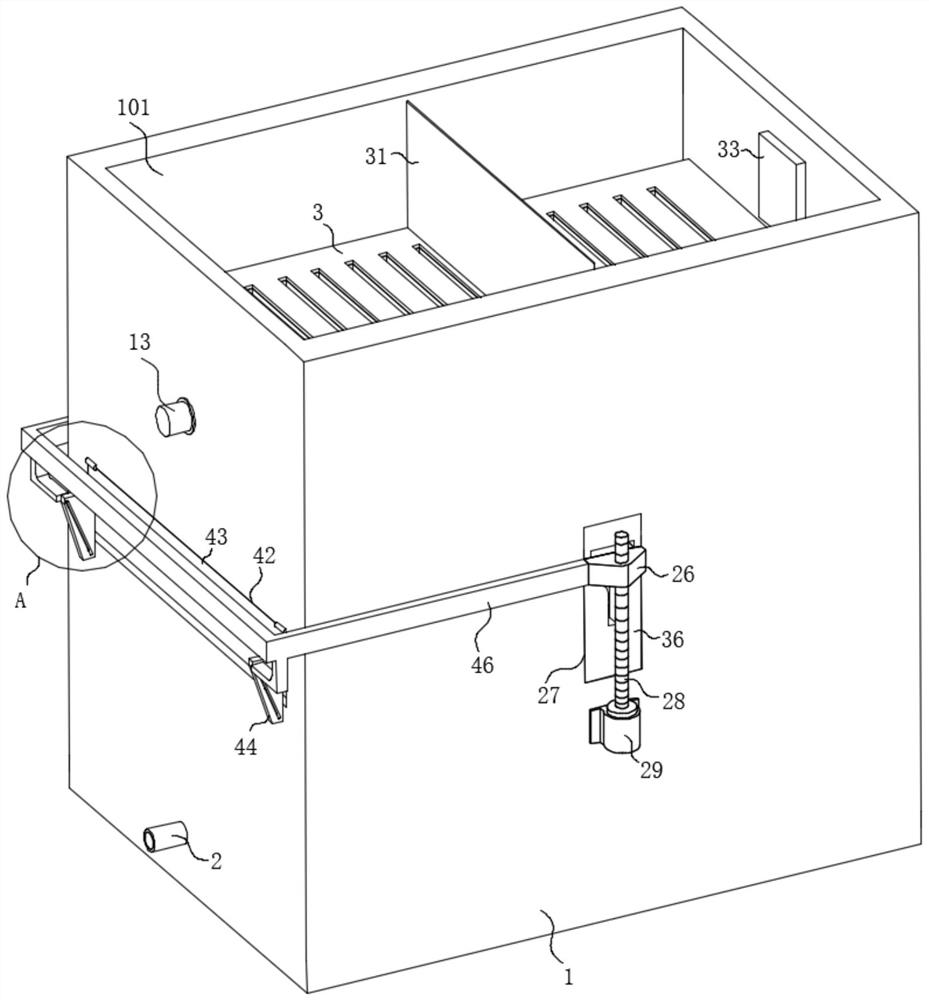

An integrated circuit lead frame etching solution recovery device

A lead frame and integrated circuit technology, applied in the direction of electrolysis components, electrolysis process, instruments, etc., can solve the problems of limited electrolysis capacity, residue, single treatment method, etc., and achieve the effect of improving the degree of automation, improving the ability of processing, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

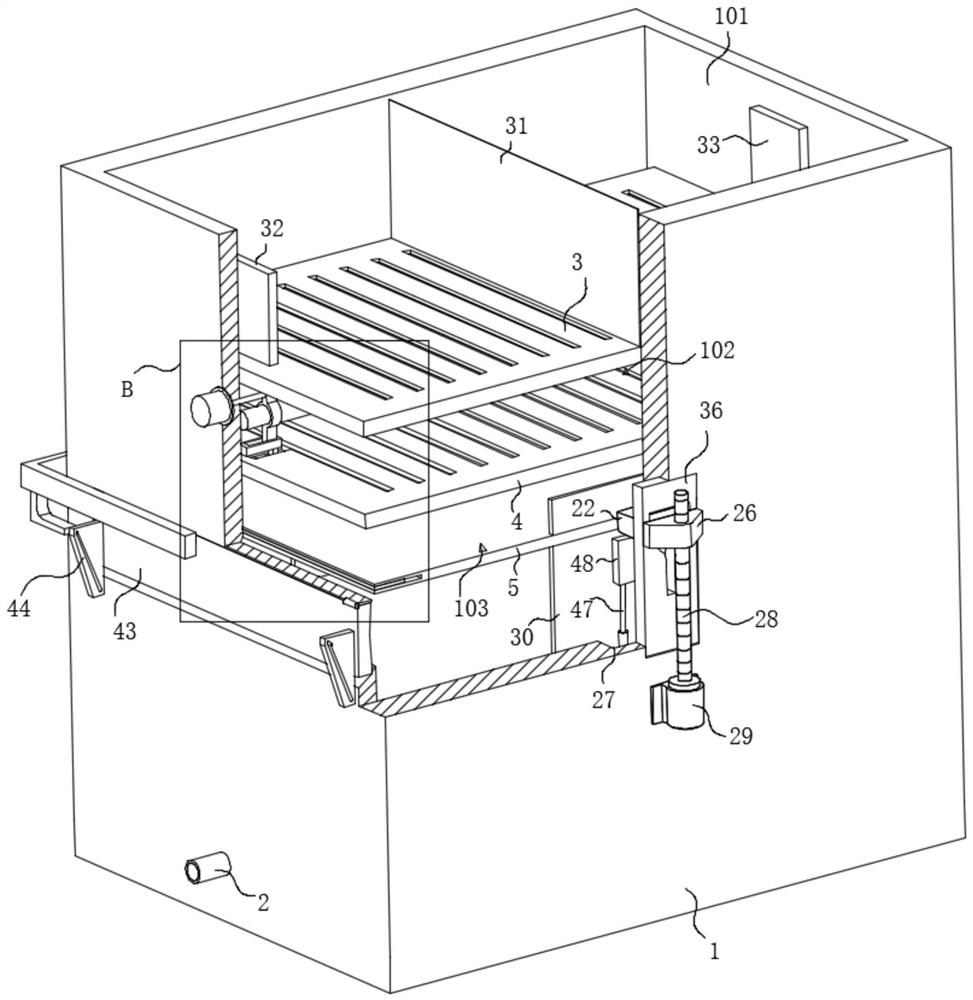

[0040] As an embodiment of the present invention, the second liquid discharge mechanism includes a second installation groove 15 and a second through port 16 , the second installation groove 15 is opened inside the second partition plate 4 , and the inner wall of the second installation groove 15 A second sealing plate 17 is slidably sealed on the upper side. A second return spring 18 is fixedly connected between the right end of the second sealing plate 17 and the inner wall of the second installation groove 15. The top of the second sealing plate 17 is provided with a linear array of The second communication groove 19, the second through port 16 is opened in a linear array on the top of the second partition plate 4, the second through port 16 and the second communication groove 19 are arranged in a staggered position, and the right side of the top of the second sealing plate 17 is fixedly connected with a In the second linkage block 20, the top of the second sealing plate 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com