A color 3D printer extrusion nozzle

A technology of 3D printers and nozzles, which is applied in coating devices, additive processing, etc., and can solve problems such as the difficulty of achieving color printing with a single nozzle, color 3D printing, and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

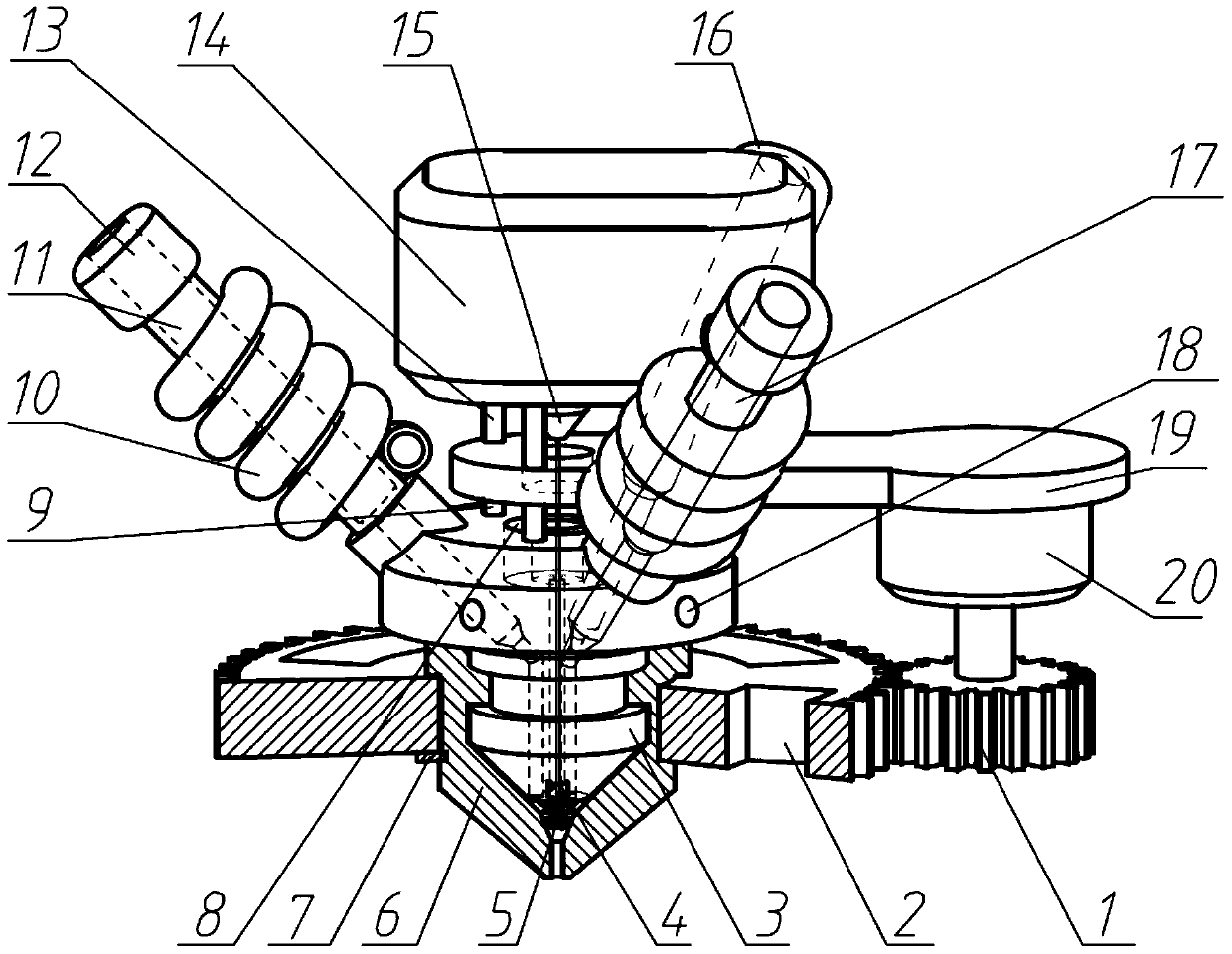

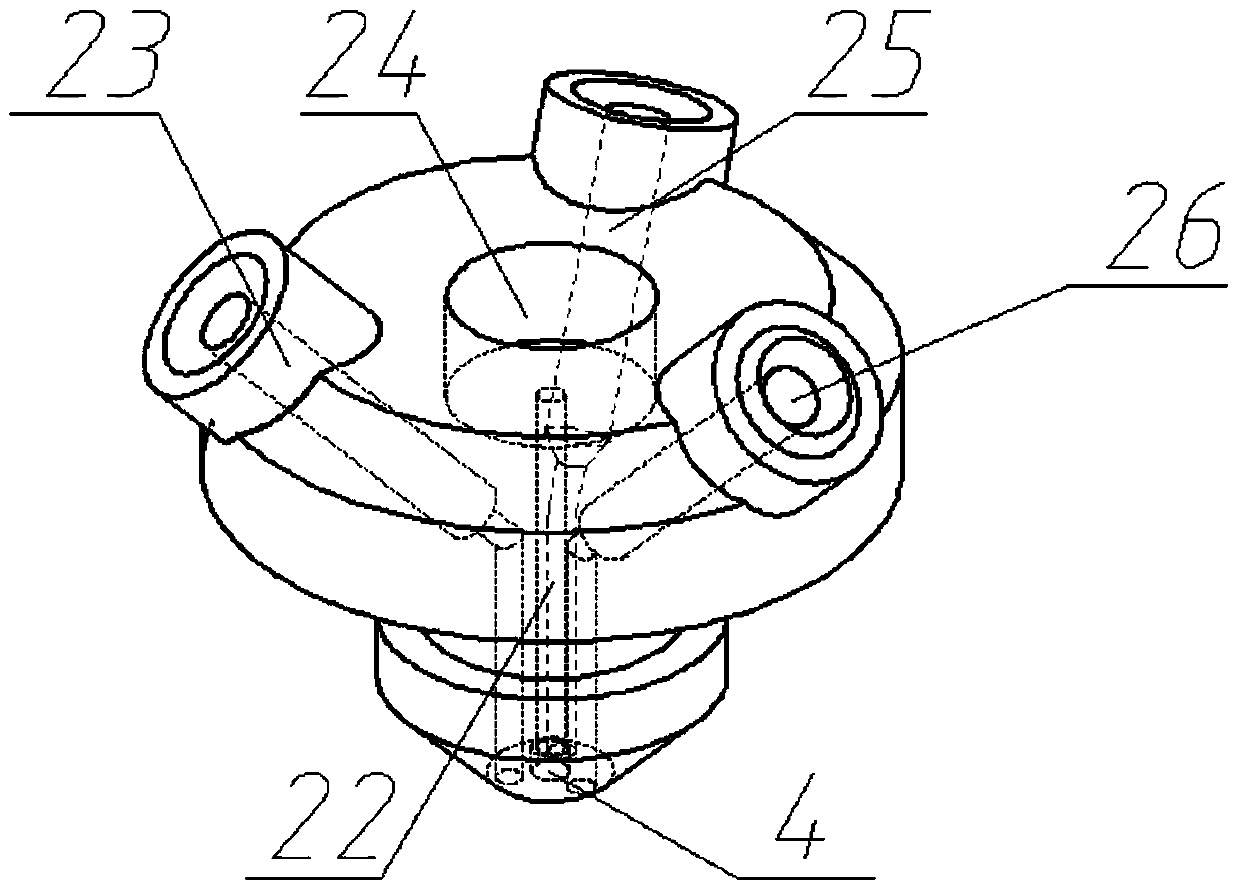

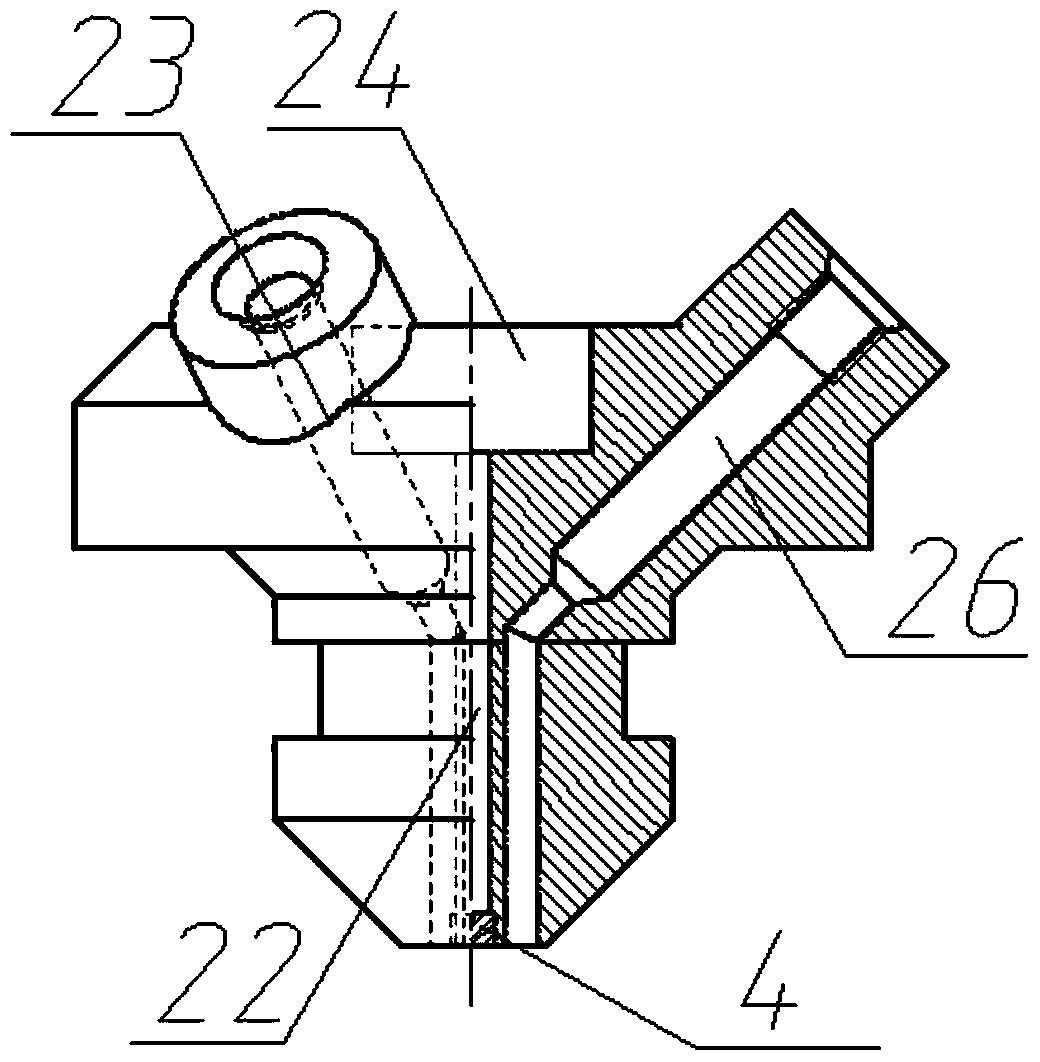

[0020] combine Figure 1~4 , an extrusion nozzle of a color 3D printer in the present invention, comprising a small gear 1, a large gear 2, a nozzle 3, a heat-resistant glass 4, a micro stirring rod 5, a rotary sleeve 6, a retaining ring 7, a resistance wire heater 8, a screw Column I 9, water cooling pipe 10, throat 11, feeding assembly I 12, stud II 13, laser heater 14, laser head 15, feeding assembly II 16, feeding assembly III 17, temperature detector 18, motor Support 19, stepping motor 20, conical mixing chamber 21, through hole 22, flow channel I 23, annular groove 24, flow channel II 25, flow channel III 26 are arranged in the nozzle 3.

[0021] The feed components I-III, the motor bracket 19 and the resistance wire heater 8 are installed on the rotary mixing nozzle assembly, and the laser heater 14 is installed on the motor bracket 19 . The motor bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com