Solid phase and liquid phase compound dynamic gas preparation device and gas preparation method

A dynamic gas distribution and compound technology, applied in the direction of mixing methods, chemical instruments and methods, measuring devices, etc., can solve the problems of permeation tube structure depletion, lack, cumbersome operation, etc., to simplify operation, expand types, and shorten analysis time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

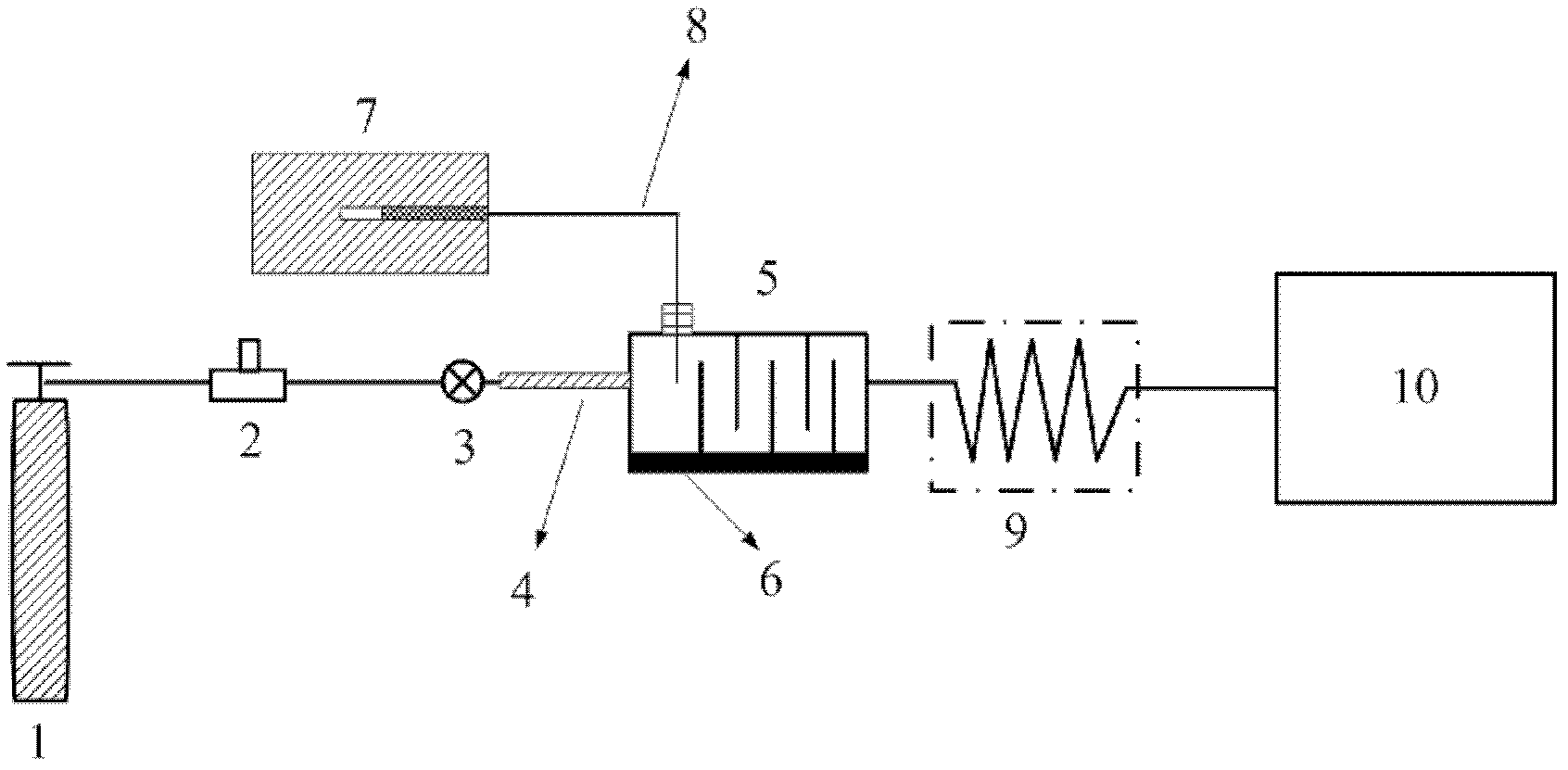

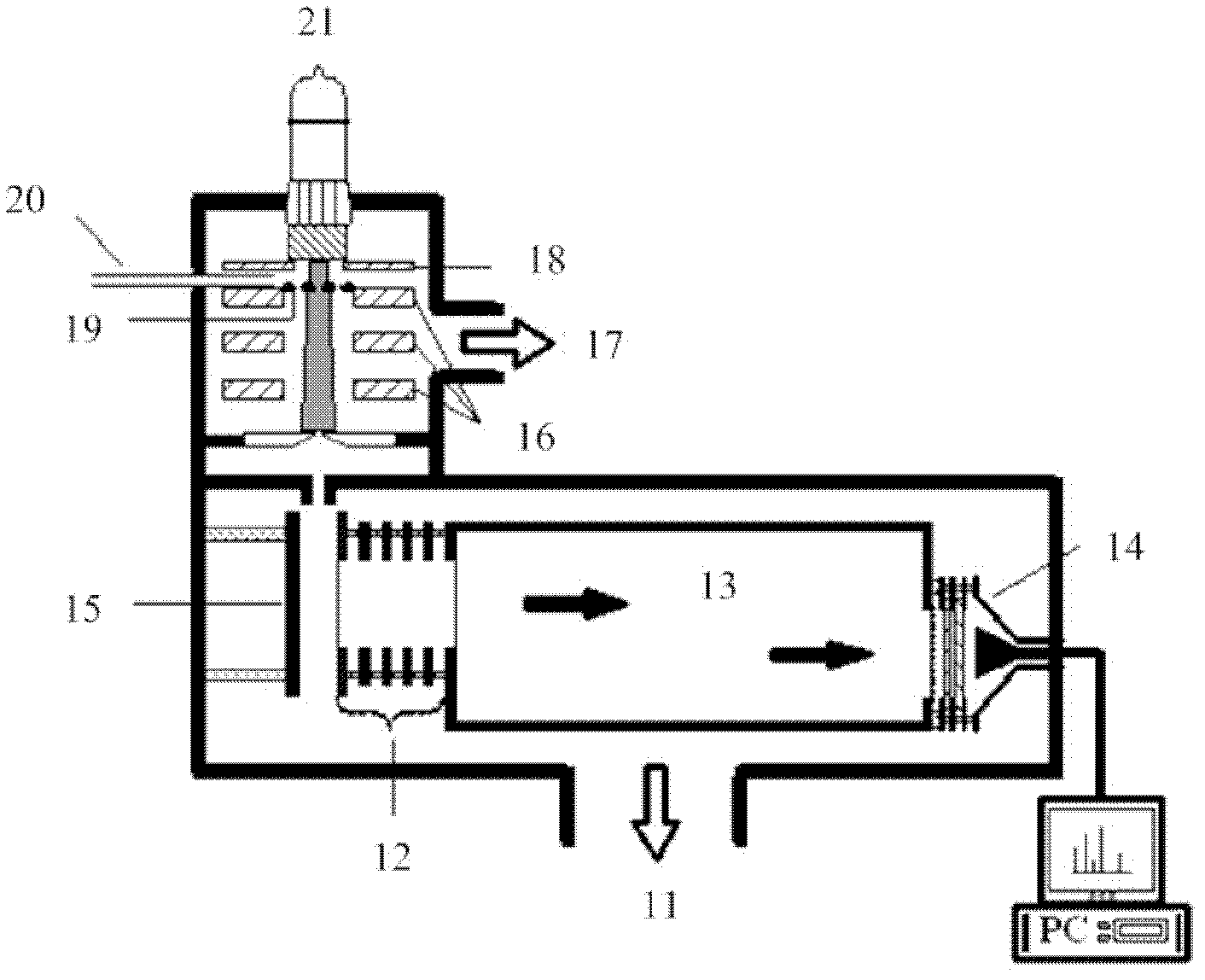

Method used

Image

Examples

Embodiment 1

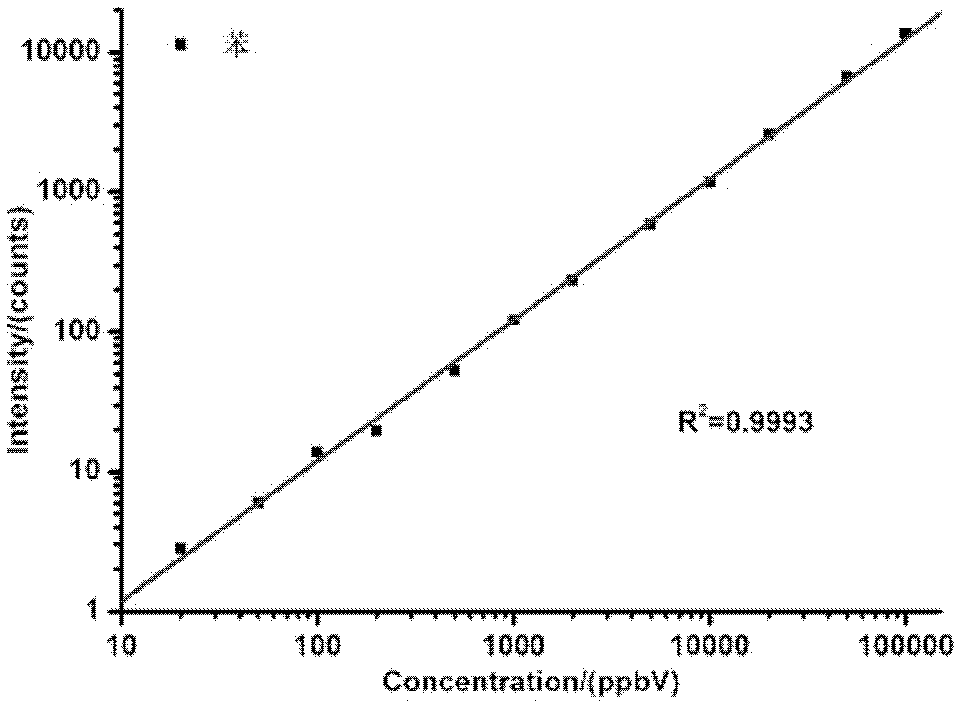

[0081] For the examination of the dynamic gas distribution system and gas distribution method performance of a kind of solid phase and liquid phase compound described in the present invention, experiment is solvent with methanol, prepares four kinds of concentrations to be respectively 5.6 * 10 -4 mol / L, 5.6×10 -3 mol / L, 5.6×10 -2 mol / L, 5.6×10 -1 mol / L benzene solution. Set the flow rate of the diluent gas to 4L / min, the chamber temperature to 75°C, and for the concentration to be 5.6×10 -4 mol / L sample standard solution, when the flow rate of the micro syringe pump is 2.5μl / min, 5μl / min, 12.5μl / min, the corresponding standard gas concentration is 10ppbv, 20ppbv and 50ppbv respectively. By analogy, when the flow rates of the micro-injection pumps are 2.5 μl / min, 5 μl / min, and 12.5 μl / min, the concentrations are 5.6×10 -3 mol / L, 5.6×10 -2 mol / L, 5.6×10 -1The concentration of the standard gas corresponding to the sample standard solution in mol / L is easy to obtain. In th...

Embodiment 2

[0083] For the examination of the dynamic gas distribution system and gas distribution method performance of a solid phase and liquid phase compound described in the present invention, the experiment uses pure water as solvent, and prepares four kinds of concentrations that are respectively 6.54×10 -5 mol / L, 6.54×10 -4 mol / L, 6.54×10 -3 mol / L, 6.54×10 -2 mol / L, 6.54×10 -1 mol / L solution of methyl tert-butyl ether and 2-butanone. Set the flow rate of the diluent gas to 0.5L / min, the temperature of the chamber to 120°C, and the temperature of the gas mixing part to 120°C. For a concentration of 6.54 x 10 -5 mol / L sample standard solution, when the flow rate of the micro syringe pump is 2.5μl / min, 5μl / min, 12.5μl / min, the corresponding standard gas concentration is 10ppbv, 20ppbv and 50ppbv respectively. By analogy, when the flow rates of the micro-injection pumps are 2.5 μl / min, 5 μl / min, and 12.5 μl / min, the concentrations are 5.6×10 -3 mol / L, 5.6×10 -2 mol / L, 5.6×10 -1...

Embodiment 3

[0085] For the examination of the dynamic gas distribution system and gas distribution method performance of a kind of solid phase and liquid phase compound described in the present invention, experiment is solvent with ethanol, prepared four kinds of concentration respectively to be 6.54 * 10 -5 mol / L, 6.54×10 -4 mol / L, 6.54×10 -3 mol / L, 6.54×10 -2 mol / L solution of naphthalene and methyl salicylate. Set the flow rate of the diluent gas to 0.5L / min, the temperature of the cavity to 120°C, and the temperature of the gas mixing part to 120°C. For a concentration of 6.54 x 10 -5 mol / L sample standard solution, when the flow rate of the micro injection pump is 2.5μl / min, 4μl / min, 5μl / min, 8μl / min, 10μl / min and 12.5μl / min, the corresponding standard gas concentration is 10ppbv , 16ppbv, 20ppbv, 32ppbv, 40ppbv and 50ppbv. By analogy, when the flow rates of the micro-injection pumps are 2.5 μl / min, 5 μl / min, and 12.5 μl / min, the concentrations are 5.6×10 -3 mol / L, 5.6×10 -2 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com