Automatic material feeding and blending, smoke prevention, dust control and emission reduction integrated system for electric furnace

A smoke and dust removal, electric furnace technology, applied to furnaces, furnace components, electric charge control, etc., can solve the problems of high labor intensity of operators, endangering employees' personal health, requiring many operators, etc., to achieve space saving, strong vibration, The effect of various forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

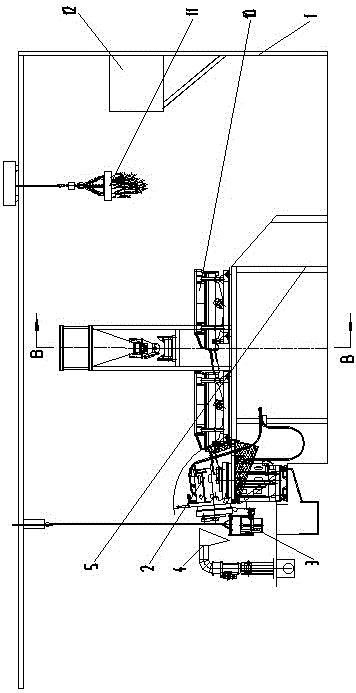

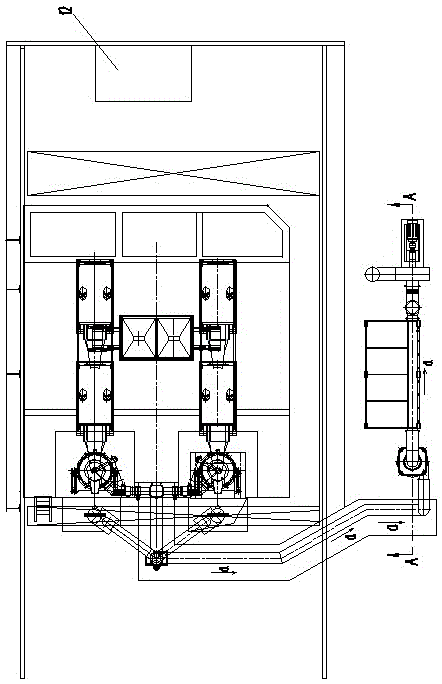

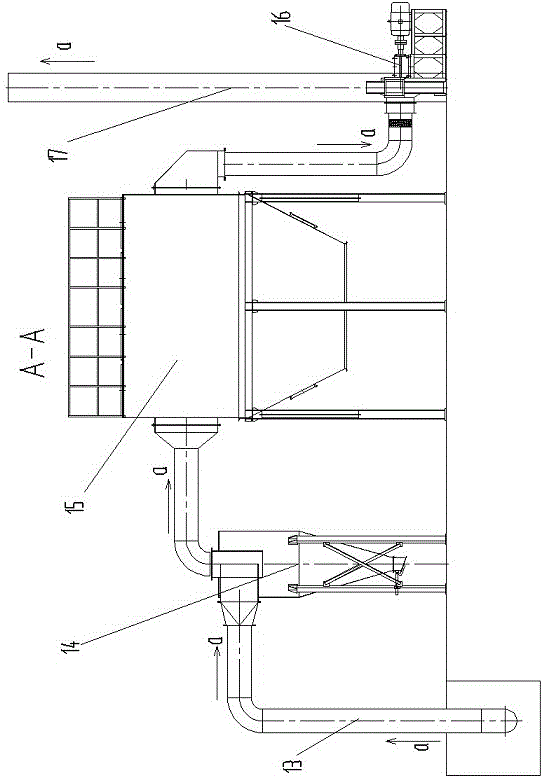

[0026] exist Figure 1 ~ Figure 4 Among them, the integrated system of automatic batching and smoke elimination, dust removal and emission reduction for electric furnaces of the present invention includes a frame 1, an electric furnace 2 installed on the lower platform of the frame, and a spheroidizing bag that is close to the front side of the electric furnace and hung on the top platform of the frame 3. The spheroidization dust collection system 4 installed close to the spheroidization bag, the batching rack 5 located on the rear side of the electric furnace and installed on the lower platform of the rack, and the alloy gold high-level silo 6 installed on the top of the batching rack, installed on the mating The electromagnetic vibrating feeder 7 under the gold high-level silo is located below the discharge port of the electromagnetic vibrating feeder and is hung on the matching alloy weighing hopper 8 on the gold high-level silo. It is located under the alloy weighing hopper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com