Aggregate preparing system of civil engineering materials

A batching system and aggregate technology, applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of limited mixing volume, difficult to find weighing deviation, low batching efficiency, etc., to improve batching accuracy and mixing output, Avoid the effect of slow static weighing speed and reliable and durable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following detailed description, certain exemplary embodiments of the present invention are shown and described, simply by way of illustration. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit or scope of the present invention. Accordingly, the drawings and descriptions are to be regarded as illustrative in nature, and not restrictive.

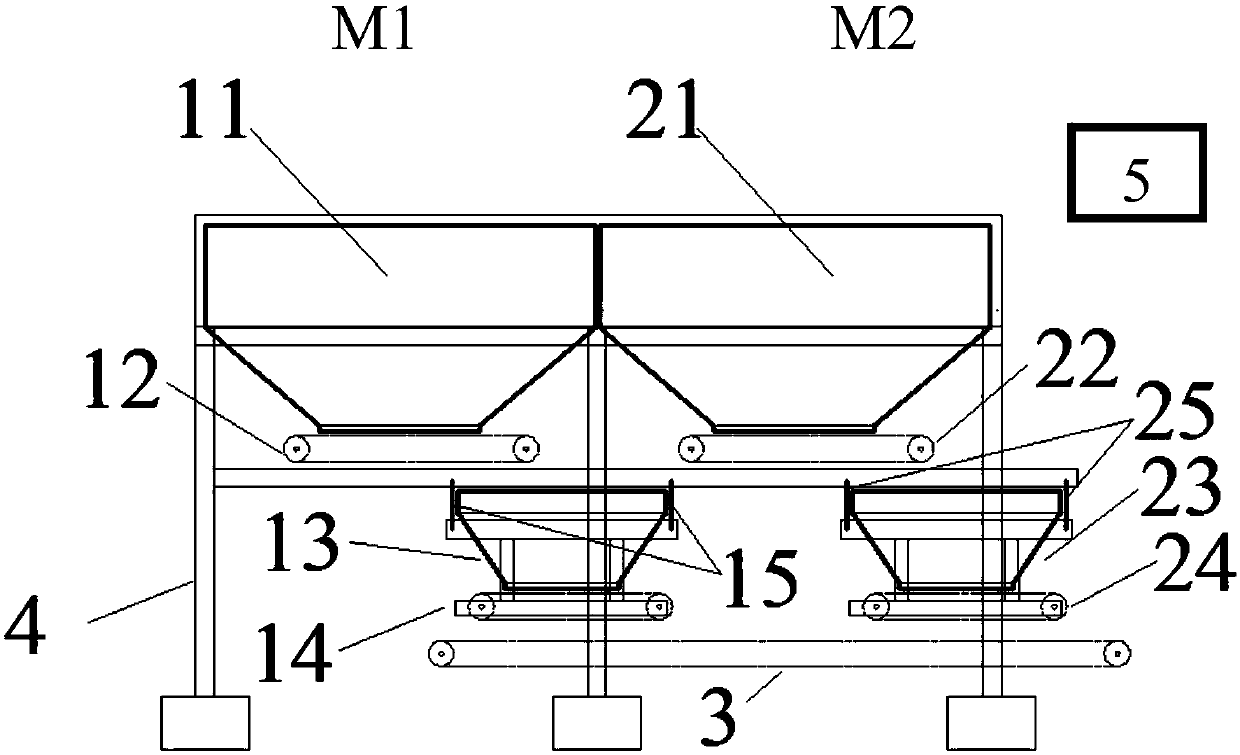

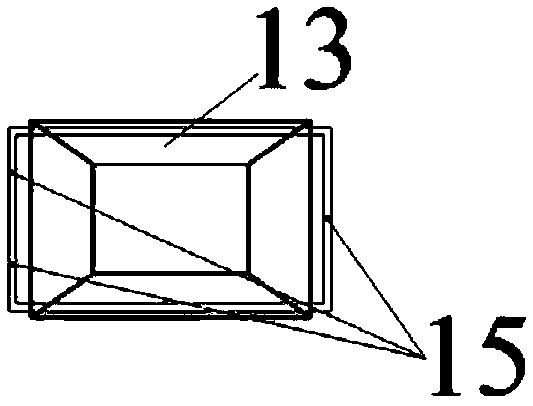

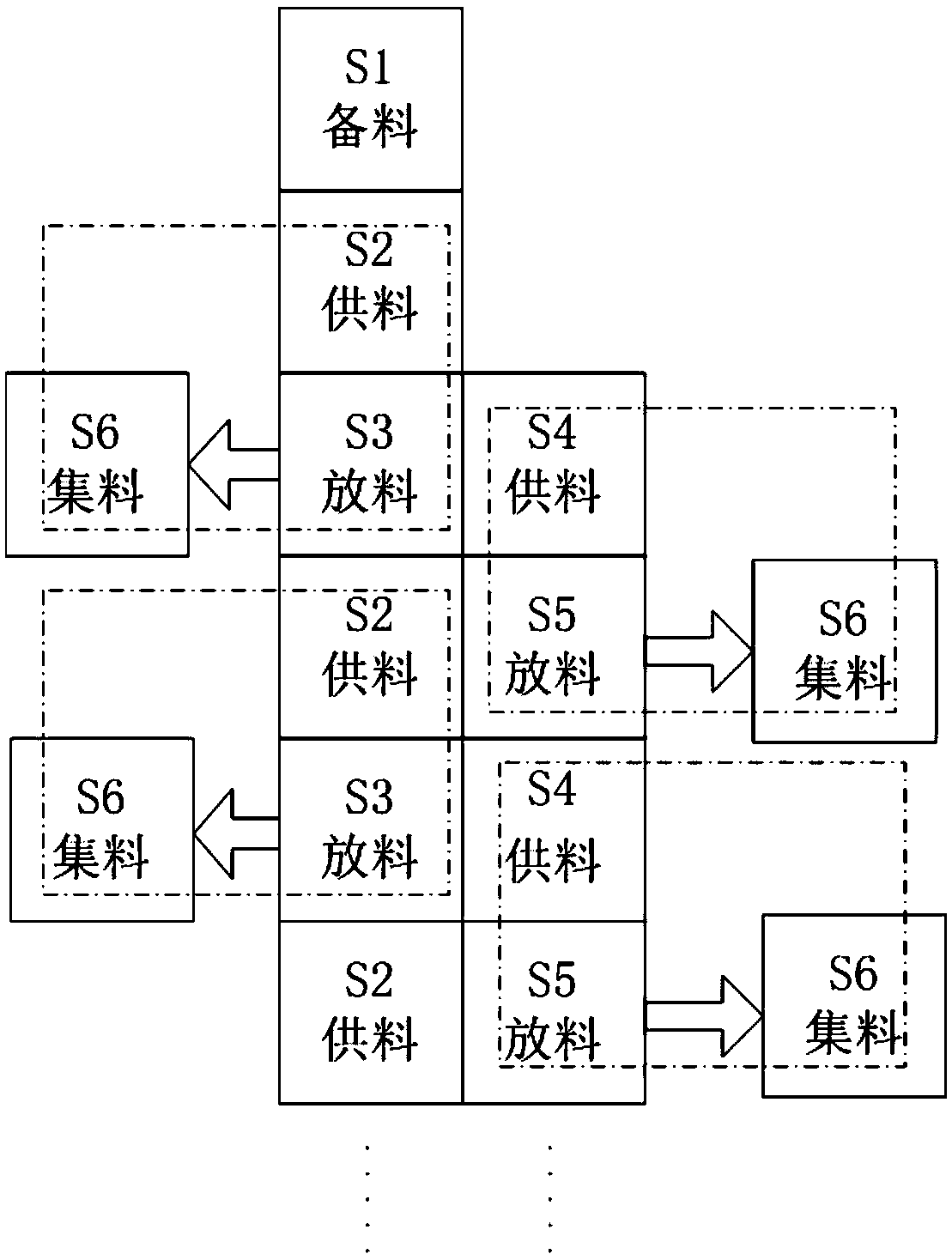

[0027] Such as figure 1 As shown, according to a preferred embodiment of the present invention, an aggregate batching system for civil construction materials includes: a first batching module M1, including a first aggregate bin 11, a first feeding belt 12, and a first weighing hopper 13 , the first discharge belt 14 and the first weighing sensor 15; the second batching module M2, including the second aggregate bin 21, the second feed belt 22, the second weighing hopper 23, the second discharge belt 24 and The second weighing sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com